Vietnam’s export of cassava chips and cassava-made products increased in 2020, with 2.76 million tonnes worth $989 million being exported, up 9% in volume and 2.4% in value compared to 2019. China was the largest export market, followed by Taiwan and Malaysia. Although the COVID-19 pandemic caused some problems for the cassava production industry, it was still one of the few agricultural products with a positive growth in export value.

An Overview

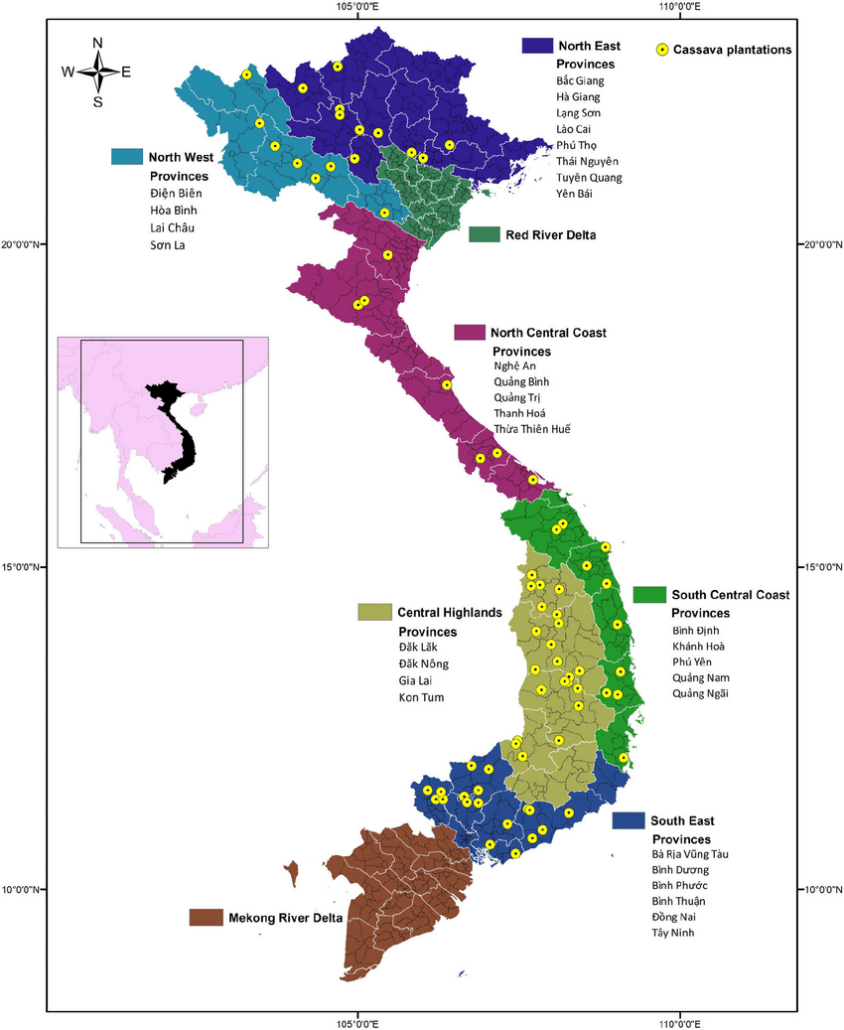

Cassava is cultivated in several regions across Vietnam, including:

- The South: Tay Ninh Province, Binh Phuoc Province, Dong Nai Province, Binh Thuan Province.

- The Central Highlands: Gia Lai Province, Daklak Province, Dak Nong province.

- The Central Coast: Quang Ngai Province, Binh Dinh Province, Phu Yen Province, Quang Nam Province, Nghe An Province, Quang Tri province.

- The North (smaller quantity compared to the South & Central Coast): Yen Bai Province, Son La Province, Hoa Binh Province.

Cassava is typically planted between January and April, depending on the region and climate conditions. In the north, March is the ideal time to plant cassava as the temperature begins to warm with spring rains, while in the north-central region, January is the best month for cultivation. In the south-central area, cassava is planted from January to March when temperatures are generally high and rain is common. In the highlands and south, farmers grow cassava mainly at the end of the dry season, with the rainy season in April or May being the ideal condition.

Production Process

Vietnam is home to 120 cassava starch factories, each with a processing capacity exceeding 15.5 million tonnes, according to the Vietnam Cassava Association. With the advent of high-yielding cassava varieties and sustainable production techniques, cassava farming has become more cost-effective in recent years, especially in the Southeast.

Vietnam tapioca starch is primarily produced through the wet milling of fresh cassava roots. Good-quality, mature cassava tubers may contain about 25% starch. About 60% starch and 10% dry pulp can be recovered from 100 kg of dry cassava chips.

The process involves eight steps:

- Weigh the fresh cassava roots to determine the starch content.

- Remove sand and impurities with a rotary screener.

- Peel, clean, and slice the cassava roots.

- Process the cleaned cassava in the Rasper and decant to remove the protein.

- Remove fiber from the slurry using a screen. Sun-dried fiber can be used for animal feed.

- Use a Centrifuge machine to separate the fine fiber and impurities.

- Dry the starch in a hot-air dryer until it contains only 12-13 percent moisture, making it suitable for sale.

- Sift and pack the fine powder into sacks for sale.

Types of tapioca starch

Vietnam produces four main types of tapioca starch, including native starch, modified starch, progelatinized starch, and waxy starch. Among these, native starch and modified starch are the major products exported to other countries. Native starch is derived directly from the extraction of cassava roots and is widely used in various industries such as food, paper, and textile. On the other hand, modified starch undergoes chemical and physical processes to enhance its properties such as its texture, viscosity, and stability. It is commonly used as a thickener, stabilizer, and emulsifier in the food industry.

Some of the specific types of tapioca starch products that are exported from Vietnam include:

- Pregelatinized tapioca starch: Pregelatinized starch is a modified form of starch that has undergone a thermal and mechanical process to rupture and gelatinize the starch granules, resulting in a product with cold-water solubility and thickening properties.

- Oxidized Starch E1404: obtained by treatment of food starch in accordance with good manufacturing practices (GMP) with sodium hypochlorite. Oxidation involves the deliberate production of carboxyl groups.

- Starch Acetate (E1420): obtained by esterification of food starches with acetic anhydride or vinyl acetate. The esterification/acetylation results in substitution of hydroxyl groups with acetyl esters.

- Distarch Phosphate (E1412): obtained by cross-linking starch using sodium trimetaphosphate or phosphorus oxychloride.

- Phosphated Distarch Phosphate (E1413): obtained by esterification/cross-linking of food starch with sodium trimetaphosphate or phosphorus oxychloride combined with esterification with ortho-phosphoric acid, or sodium or potassium ortho-phosphate, or sodium tripolyphosphate, in accordance with good manufacturing practice (GMP)

- Acetylated Distarch Phosphate (E1414): obtained by esterification/cross-linking of food starch with sodium trimetaphosphate or phosphorus oxychloride combined with esterification with acetic anhydride or vinyl acetate.

- Acetylated Distarch Adipate (E1422): obtained by esterification of food starch with acetic anhydride and esterification/cross-linking with adipic anhydride.

- Starch Sodium Octenyl Succinate (E1450): obtained by esterification of food starch with octenyl-succinic anhydride, and neutralization with either sodium hydroxide or sodium carbonate as a pH buffer.

- Acetylated Oxidized Starch (E1451): obtained by treatment of food starch with sodium hypochlorite followed by esterification with acetic anhydride.

- Native starch: Unmodified tapioca starch that is used as a thickener, stabilizer, and binder in a variety of food products.