The influence of certain processing conditions on the quality, functional properties, and product potential of flour made from three cassava cultivars are being evaluated as part of a project (DGXII) funded by the European Union (EU). The collaborators in this project are the Universidad del Valle (UNIVALLE), Colombia; CIRAD-SAR, France; the Natural Resources Institute (NRI), UK; and CIAT, Colombia.

The influence of drying temperature (40, 60, and 80 °C), milling procedure (hammer, roller, pin, and paddle), and particle size (< 250 µm and < 160 µm) on the quality, functional properties, and product potential of flour from three cassava cultivars are being evaluated. The influence of genetic variability on starch quality is also being evaluated, using starches made from cultivars chosen from the cassava core collection established at CIAT.

This chapter outlines the results so far.

Materials and Methods

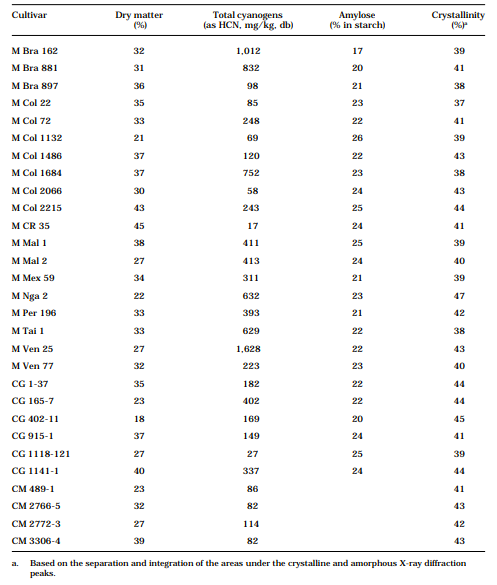

The cassava cultivars used in this research were selected after the cassava core collection, held at CIAT, Cali, Colombia, was evaluated (Wheatley et al., 1993). Cultivars were selected to represent a broad variability in root contents of cyanogens, dry matter, and amylose.

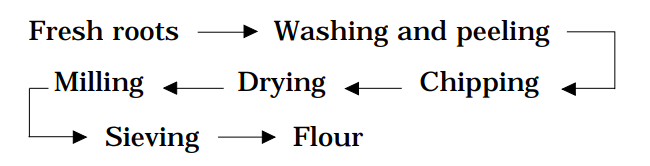

Experiments were designed to determine how flour preparation influences the resultant quality of the end product. In October 1992, 1,500 kg of fresh roots of the cassava cultivar CM 3306-4 were harvested at CIAT. The roots were processed into flour as outlined:

In August and September 1993, two more cultivars of cassava (CM 3306-4, M Ven 25) were harvested 10 months after planting and similarly processed.

Before drying, the chips from each cultivars were divided into three lots of 475 kg. They were then dried in a layer, about 15 cm thick, on the floor (3 m2 area) of an airflow bin dryer. Drying temperatures used were 40, 60, and 80 °C.

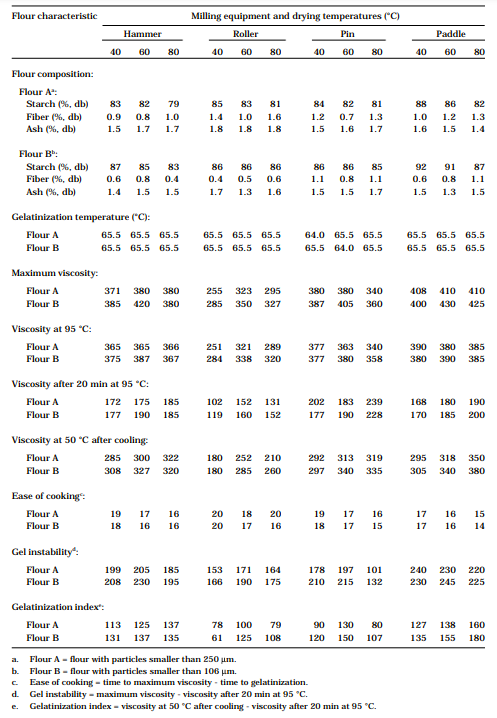

Four different types of mill were used to grind the resultant dry chips: (1) hammer mill (set at 5,800 rpm and with a 1 8 -inch screen), (2) roller mill (first pass with rollers set at 300 µm apart and second pass with rollers set at 30 µm), (3) pin mill, and (4) a paddle auger in a cylindrical sifter with a 5-mm and 250-µm screen. The flours produced were divided into two sieve fractions to give two particle sizes: smaller than 250 µm, and smaller than 106 µm.

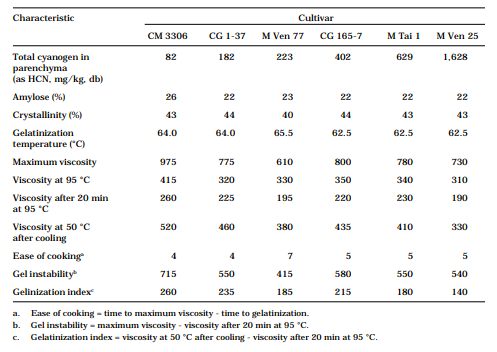

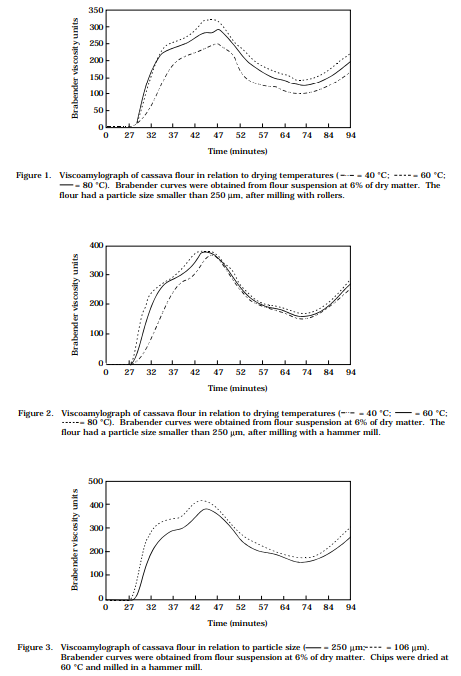

The flours produced by the different treatments were analyzed with a Brabender amylograph (BA). Gelatinization profiles were determined from 6%-starch solutions, using a heating and cooling rate of 1.5 °C/min. The temperature was increased to 95 °C, held for 20 min, and cooled at a rate of 1.5 °C/min to 50 °C. The viscographs obtained were used to calculate the following parameters: the initial temperature of gelatinization, peak viscosity, ease of cooking, gel instability, and gelatinization index.

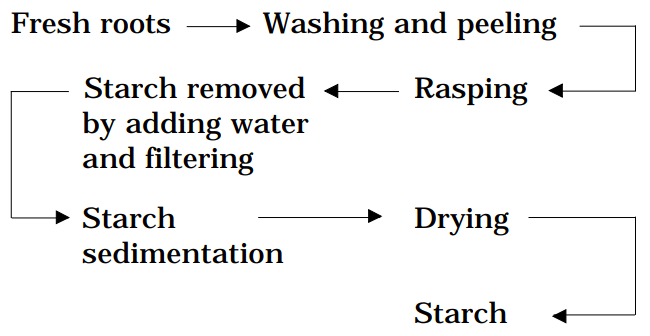

In October 1992, 29 cassava cultivars were harvested at CIAT 10 to 12 months after planting. Starch samples were extracted as outlined:

Starch samples were also prepared from another 33 cassava cultivars, including the same 29 cultivars, harvested at CIAT in July 1993 9 months after planting.

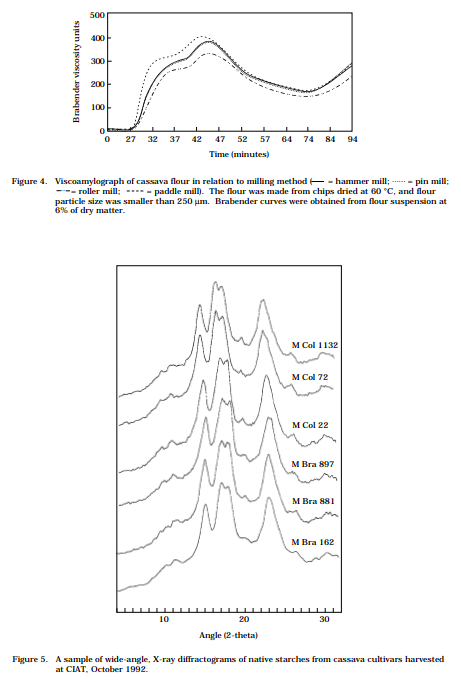

The starch samples extracted from the cassava cultivars in 1992 were analyzed with a BA. Gelatinization profiles were determined from 6%-starch solutions as described above. The amylose contents were determined, using an iodo-colometric test and a calibration curve prepared from potato amylose and amylopectin. The crystallinity of the starch granules was determined with an X-ray diffraction system. The diffraction data were collected over an angular range from 4° to 32° 20’.

Starch samples from both harvests will be examined for granular size distribution,.amylose-to-amylopectin ratio, chain length, degree of polymerization, X-ray diffraction patterns and absolute crystallinity, differential scanning calorimetry (DSC) analysis, pasting and rheological characteristics, swelling power and solubility, and water-binding capacity.

Results

Flour

The various processing procedures used in these experiments all influenced the gelatinization profiles of the resultant flours (Figures 1 to 4; Table 1). Whether the differences obtained in gelatinization properties are enough to significantly influence the potential uses of the flours is yet to be determined. At the time of writing, the flours prepared from the cultivars harvested and processed in August and September 1993 were not yet analyzed.

Starch

Figure 5 shows a sample of the X-ray diffractograms obtained from starches made from the roots of the October 1992 harvest. All spectra of the 29 cultivars analyzed showed an A-type, X-ray diffraction pattern. Table 2 gives values calculated for starch crystallinity and amylose content, together with the analysis reported by CIAT of root dry matter and cyanogen contents. Table 3 gives the gelatinization profiles of starch samples analyzed. The results obtained show a similar trend to that reported by Wheatley et al. (1993). Differences in starch viscosity characteristics were observed between cultivars with high and low cyanogenic content. Research is continuing with the 33 starch samples obtained from cultivars harvested in July-August 1993.