Cassava has become a major cash crop for Thailand: in 1993, production was about 21 million tons, and increasing (TDRI, 1992). About 90% of total production is exported, mainly to Europe. Although cassava is mostly processed into pellets and chips for animal feed, the volume of these products has decreased slightly during the last decade in favor of cassava flour and starch for domestic industry and export (Table 1).

| Year | Sago | Chips | Pellets | Starch | Total prod. (x1000) |

| 1982 | 2,397 | 523,059 | 6,892,786 | 396,754 | 17,788 |

| 1983 | 2,948 | 279,913 | 4,554,332 | 359,298 | 18,989 |

| 1984 | 5,831 | 137,808 | 5,975,136 | 449,183 | 19,985 |

| 1985 | 7,566 | 123,702 | 6,474,503 | 482,309 | 19,263 |

| 1986 | 5,243 | 35,699 | 5,842,468 | 435,154 | 15,255 |

| 1987 | 7,420 | 72,833 | 5,777,137 | 353,594 | 19,554 |

| 1988 | 6,663 | 312,460 | 7,334,446 | 452,199 | 22,307 |

| 1989 | 9,223 | 130,201 | 9,185,466 | 501,329 | 24,264 |

| 1990 | 8,447 | 210,814 | 7,316,368 | 531,365 | 20,701 |

| 1991 | 10,060 | 113,205 | 6,269,458 | 549,022 | 19,705 |

In 1990/1991, although 96 cassava starch processing factories were registered, only 55 were operating. Total production capacity was 1.5-1.8 million tons, of which 50% was for export, 25% for food-processing, and 25% for nonfood industries.

In 1991, the 55 cassava starch factories could be classified into 46 starch factories and 9 modified-starch factories. Monosodium glutamate (MSG) processing ranks highest among those cassava starch processing industries manufacturing amino acids (Table 2; Rodsri, 1993). Recently, lysine has become available and is used as a nutrient in feed mills. At present, the Thai Government is planning to support research that would help diversify the use of cassava starch in various industries to prevent falling prices. Cassava starch industries only produce 50%-70% of their total capacity, and thus have potential for further development.

| Uses | Percentage of total use |

| Direct consumption | 26 |

| Industry: | |

| Monosodium glutamate | 19 |

| Glucose syrup | 15 |

| Paper | 9 |

| Food | 7 |

| Sago | 6 |

| Textiles | 2 |

| Timber | 1 |

| Other | 15 |

| Total | 100 |

Production and Development of Cassava Flour

Two kinds of cassava flour-processing factories operate in eastern Thailand: traditional and modern.

Traditional factories

Flour-processing factories were first built in the early history of cassava production in Thailand. The model of operation—a family business that employs now-obsolete technology—is still common in some parts of Thailand. Cassava roots are first crushed, then soaked in water. The resulting starch is extracted, sun dried, and pulverized into flour, which, however, is inferior in quality and bulk. It is used for making such products as noodles, desserts, and sago, most of which are sold on local markets.

Modern factories

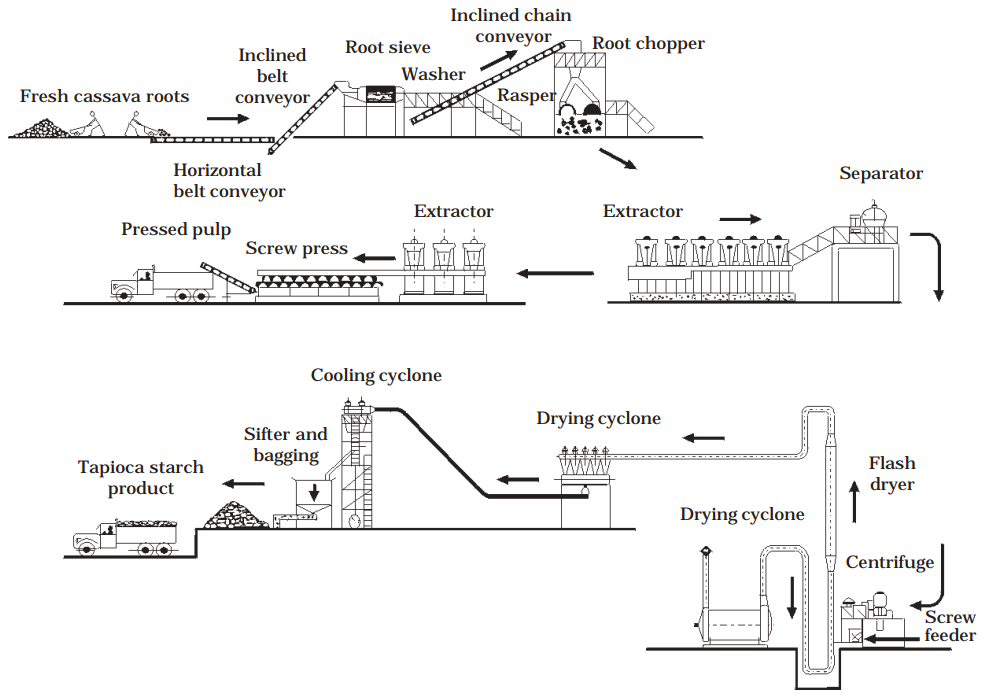

Many flour-processing factories have been modernized since World War II to produce high-quality cassava flour for export and use in domestic industry. The role of cassava thus changed from being a local crop for domestic consumption to a major commercial crop for export. At present, modern processing equipment is being developed for export to neighboring countries such as China, Vietnam, and Indonesia. The capacity of such equipment ranges from 50 to 100 t/day (Figure 1). In modern processing:

- Cassava roots are weighed and measured for their starch content.

- The roots are precleaned by a soil separator, then passed through a cleaning machine and peeler. Peeling makes extracting starch easier.

- The roots are then crushed and liquid starch is extracted, leaving a cake, which is sun dried before being used as a supplementary feed or for producing cassava chips and pellets.

- The liquid starch is purified by passing it through a sulfur vapor to rid the starch of sap.

- Water is then filtered out and the starch dried mechanically. It is then packed and shipped to markets.

On the average, 1 kg of fresh roots yields 200 g of starch and between 40 and 90 g of cake. Cassava flour quality depends on the manufacturing process. If the process is efficient and clean, the flour will be of high quality. Quality is judged by granule size; flour color, smell, and purity; fiber and ash contents of flour; humidity, acidity, and viscosity of liquid starch; and cake. At present, a cassava breeding program has been established to develop varieties that have high starch content: 22%-24%, depending on the growing season.

Standard Specifications for Starch for Export and Local Markets

The Ministry of Commerce has established specifications for inspecting and controlling cassava flour and starch for export.

Certified products must be inspected according to Ministry standards and/or importer specifications. “Cassava flour/starch” is defined as that “obtained from cassava root [as] a white or cream-colored powder that does not include modified starch.” Cassava flour and starch are graded at three levels, each with its own specifications (Table 3; Ministry of Commerce, 1993).

| Characteristics | Supreme grade | First grade | Second grade |

| Starch (day basis) (%) | 85 | 83 | 80 |

| Moisture content (%) | 13 | 14 | 14 |

| Ash (%) | 0.2 | 0.3 | 0.5 |

| Fiber (cm3/50 g flour) | <0.2 | <0.5 | <1.0 |

| pH | 4.5-7.0 | 3.5-7.0 | 3.0-7.0 |

| Particle size (mesh hole = 150 µm) (%) | 99 | 97 | 95 |

Standards for cassava flour and starch used locally were established in 1974 by the Thai Industrial Standard, Ministry of Industry: “Flour/starch obtained from cassava roots (Manihot utilissima) has starch granules of microscopic appearance, consisting of a cluster of two to eight granules, each granule measuring 5 to 35 µm and having an average diameter of 15 µm. Most starch granules are oval or truncated at one end to form a kettledrum shape while the other end has a cutting edge with the inner surface concave or irregularly flat. Starch granules clearly show an eccentric hilum with segment lines.” The quality of local flour and starch is classified into three grades (Table 4; Ministry of Industry, 1978).

| Characteristics | Grade 1 | Grade 2 | Grade 3 |

| Starch (dry basis) (%) | 97.5 | 96.0 | 94.0 |

| Moisture content (%) | 13 | 14 | 14 |

| Ash (%) | 0.15 | 0.30 | 0.50 |

| Ash (acid insoluble) (%) | 0.05 | 0.10 | 0.15 |

| Protein (%) | 0.3 | 0.3 | 0.3 |

| Fiber (cm3/50 g flour) | 0.2 | 0.5 | 1.0 |

| pH | 4.5-7.0 | 3.5-7.0 | 3.0-7.0 |

| Particle size (mesh hole = 150 µm) (%) | 1 | 3 | 5 |

Both bulk and retail packers can stamp the appropriate grade mark on packets for consumers’ selection. Retail packs are for home cooking. Information on using composite flour (that includes cassava flour) in foodstuffs is readily available at local bookshops.

Various food products from rice, bean, and wheat flours can improve their texture by substituting with cassava flour or starch.

Because cassava flour and starch are mostly processed with water, they contain no hydrocyanic acid. The Thai Standard for Cassava/Flour Starch Committee does not accept the codex standard for edible cassava flour acceptable to African countries. The African Regional Standard permits cassava flour to contain 10 mg/kg of hydrocyanic acid (FAO and WHO, 1992).

Cassava Flour and Starch in Local Food Products

Studies on incorporating cassava flour into bakery goods for the local market require research on the eating habits of the population. Because consumers prefer wheat-based products, industries using cassava flour have developed products made from mixtures of cassava and wheat flours. Such composite flours impart a unique taste and texture to the products.

Sponge cake made with cassava flour

The effect of composite flour on the quality of sponge cake has been studied by Saencharoenrat (1990). He tested four kinds of wheat flour (chlorinated cake flour = CCF, unchlorinated cake flour, all-purpose flour, and bread flour) with different levels of cassava flour: 0%, 20%, 40%, 60%, 80%, and 100%. He found that, when the level of cassava flour substitution was increased, protein content, ash content, and damaged starch content decreased. Changes in moisture content and pH, however, depended on the kind of wheat flour. The gelatinization temperature of composite flours was in the same range as that of the type of wheat flour used, whereas peak viscosity in gel formation increased. Water absorption, dough stability, resistance to extension, and extensibility also decreased as the mixing tolerance index increased. Sponge cakes made with these composite flours were then evaluated.

Results showed that the different kinds of wheat flour and the levels of substitution affected several characteristics of cakes. Increased levels of substitution increased batter viscosity and specific volume of cake, but decreased specific gravity of batter and palatability of cakes. The kind of wheat flour used affected ease of cutting the cake (bread flour scored the highest), pH (lowest with CCF), and palatability (highest with CCF). Palatability scores agreed with total cake scores. The ideal composite flour was 40% cassava flour and 60% CCF, that is, no significant differences were found (at P = 0.05) in palatability between cakes made from composite flour and cakes from 100% wheat flour.

Cakes stored at room temperature could be kept for only 2 days, whereas refrigerated cakes lasted at least 7 days. Ease of cutting increased with storage time, and moisture content and palatability decreased.

Cookies made with cassava flour

Chananithithum (1986) found that the maximum substitution of cassava flour for wheat flour in baking cookies was 40%. Results showed that the spread was high, compared with that of wheat flour. Most tasters found the composite-flour cookies to be palatable.

Spread in composite-flour cookies can be markedly reduced by using an emulsifying agent. Patco-3 (50% sodium stearic lactylate and 50% calcium stearic lactylate) and BV-15 (commercial cookie improver), used at 0.5% (flour basis), produced a cookie with a spread factor not significantly different from that of cookies made with commercial cookie flour. Nor were its organoleptic properties significantly different from those of the commercial cookie.

The storage life of composite-flour cookies was not significantly different from that of wheat-flour cookies. Composite-flour cookies could keep an acceptable texture for about 3 months when stored in polythene bags, rigid plastic containers (polyvinyl chloride [PVC]), or tin boxes. The 40%-composite flour can reduce cookie prices by almost 2%, compared with wheat flour. The production of composite-flour cookies has been scaled up, using cassava flour as a raw material.

Where cookies were made with 15% full-fat soybean flour, cassava flour could substitute wheat flour by as much as 50% (Boonyasirikool et al., 1987). The product still has more than 10% protein. Palatability tests showed no significant difference between these two types of cookies. Using vanilla and cocoa flavors can enhance product quality and make it highly acceptable.

Chemically Modified Cassava Starch for Use in the Food Industry

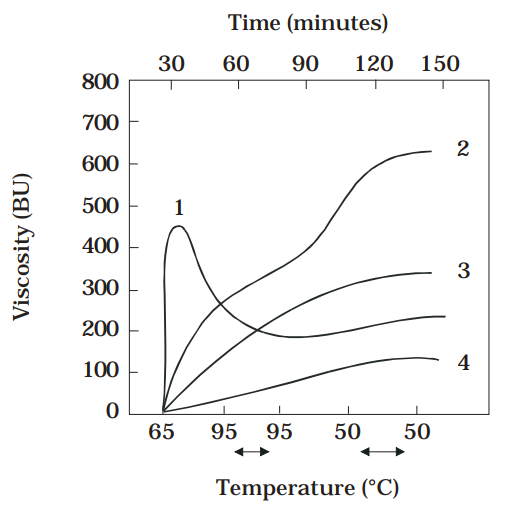

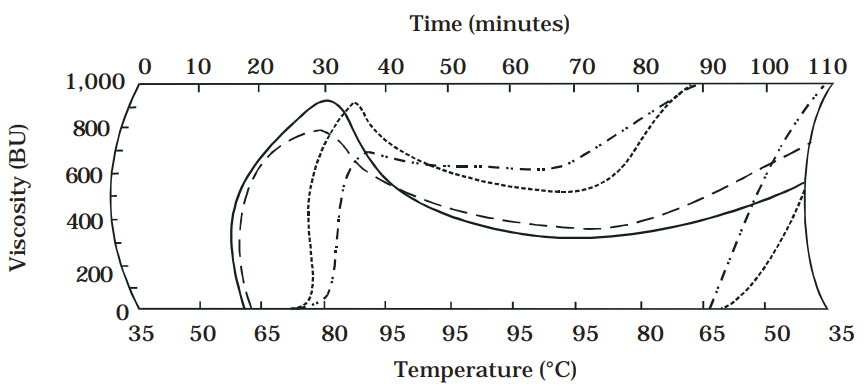

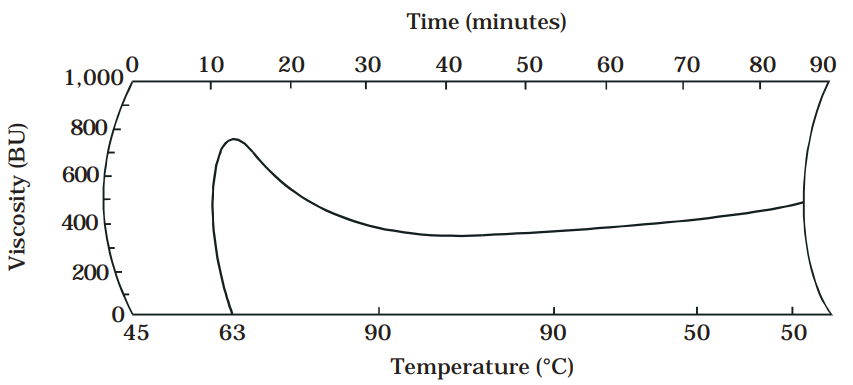

Cassava starch is a typical root starch and is used in the production of foodstuffs and adhesives. Direct use of native cassava starch is more frequent in home cooking than in industry. Root starch granules, when cooked, swell more and are more fragile (i.e., they break down easily and thin out during stirring) than are cereal starch granules. The viscosity of these starch pastes can be determined by using a Brabender viscoamylograph. After stirring, tapioca starch shows the lowest viscosity (Figures 2 and 3). When certain chemicals are introduced, they cross-link within the granule, tighten up the molecular network, restrict granule swelling, and so stabilize the viscosity of starch pastes against breakdown by agitation.

Various modified cassava starches have been developed and promoted for use in the food industry.

Cassava starch phosphate

Industries manufacturing transparent noodles, sauces, and custards have been encouraged to use cassava starch phosphate as a replacement for mung bean starch (Maneepun and Sirirojana, 1990) and as a thickening agent in sauces (Sirirojana, 1987) and custard spreads (Parvet, 1988).

Niyomvit et al. (1990) studied the use of premixed cassava starch phosphate and native cassava starch for the traditional Thai dessert, “kanom chen.” Their experiments showed that the cassava starches changed their viscosity after cross-linking with the phosphate (Figure 2). Products were prepared for tasting panels, who determined that the premixed cassava starch phosphates, of 15% (2 h), 30% (4 h), or 15% (6 h), were highly acceptable. The characteristics required were transparency, easily separating layers, and stable texture. The Instron Food Tester showed that the texture was 60%-70% more stable than that of unmodified, mixed cassava starch.

Acetylated cassava starch (A starch)

Most countries permit the use of A starch as a direct food ingredient. The degree of substitution (DS) of starch acetate is determined by hydrolyzing with excess sodium hydroxide. The digestion of sodium hydroxide is almost equivalent to acetyl content (Institute of Food Research and Product Development [IFRPD], unpublished data). Amylograms showed that the peak viscosity and stability of acetylated cassava starch are comparable with those of starches from potato, maize, and wheat (Figure 3). The acetyl substitution lowered the rate of retrogradation of cooked pastes.

When cassava substituted 30%-50% of starches from mung bean, potato, or sweetpotato in the manufacture of jelly bean sticks, the resulting product was smooth, and had good texture, gloss, and flexibility.

Acetylated and slightly cross-linked cassava starch (A/C starch)

This is called acetylated di-starch phosphate and is usually cross-linked with phosphate. The DS of acetate can be determined by hydrolyzing a hot-water-soluble, acetylated di-starch phosphate with excess sodium hydroxide (IFRPD, 1993, unpublished data). The digestion of sodium hydroxide is almost equivalent to acetyl content.

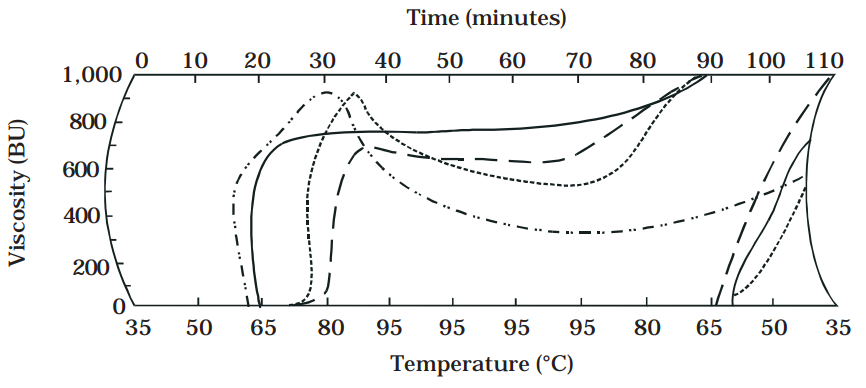

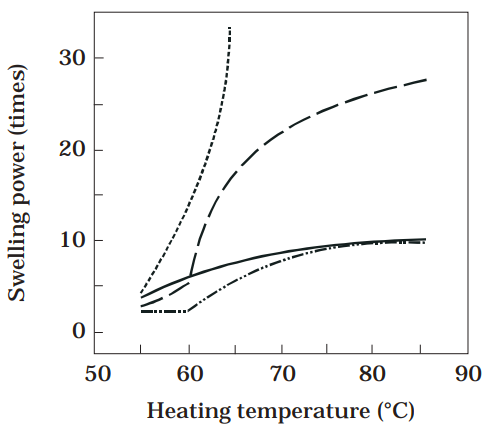

Amylograms showed that the peak viscosity and stability of viscosity were higher in A/C starch than in potato, maize, or wheat starch (Figure 4). Swelling power is also greater in A/C starch than in wheat or maize starch but lower than in potato starch (Figure 5). The A/C starch is stable under conditions of freeze-thaw, high cold storage, and acidity. It has a short texture and high transparency. The product used depends on the viscosity of final products and is recommended for use in sauces made with vinegar or fruit juice. Because A/C starch has a good affinity with raw meat and is hard to retrograde, it can be used for boiled fish paste, deep-fried fish paste, fish ham, sausage ham, sausages, and meat balls.

Both A and A/C starches can be used for making wheat noodles (oriental type), resulting in smooth noodles whose texture when cooked is stable during cold storage.

Cassava starch ether (hydroxypropyl)

The cassava starch ether is used as a food ingredient in most countries. The degree of substitution of hydroxypropyl in starch ether is ascertained by hydrolyzing with hot sulfuric acid to propionaldehyde, which is then measured with a spectrophotometer after complexing with ninhydrin (IFRPD, 1993, unpublished data). Amylograms showed that cassava starch ether has a high peak viscosity and good stability, which means it can reduce retrogradation of cooked paste (Figure 6). This starch ether is being tried out in sauce-making (acid conditions).

Standards for modified starch for the food industry

Standards were introduced to encourage cassava starch factories to produce modified cassava starch for the local market (Ministry of Industry, 1992). First published in January, 1992, these standards are upgrading modified-starch products as manufacturers apply for grade certification. The standards deal with different types of modified starch, physical and chemical additives used for modification, residues and limiting properties indicators, and methods of analysis.

Fifteen types of modified starches exist:

- pregelatinized starch,

- dextrin,

- thin boiling starch,

- alkaline treated starch,

- bleached starch,

- oxidized starch,

- di-starch phosphate,

- starch succinate,

- hydroxypropyl starch,

- starch acetate,

- monostarch phosphate,

- hydroxypropyl di-starch phosphate,

- acetylated di-starch adipate,

- acetylated di-starch phosphate,

- and combination chemical process starch.

Products of Chemical and Microbial Processing of Cassava Starch as Ingredients Used by Food Industries

Some industrial processes use cassava starch as raw material to manufacture final products that are themselves used as ingredients in foodstuffs. Such products are typically either seasonings or sweeteners. and have been developed locally and overseas. Most of the technology has been brought from developed countries with experts as consultants. Local institutions sometimes collaborate to promote further local development.

The processes are complex, involving chemical and microbial technologies that require sophisticated machinery. The final products are costly. Table 5 shows estimates of the cassava starch consumed by these industries (TDRI, 1992).

| Products | Cassava starch used (t/year) | Yield from 1 kg cassava starch (kg) |

| Seasoning industry: | ||

| Monosodium glutamate and lysine (1991) | 97,977 | 0.42 |

| Sweetening industry: | ||

| High fructose | 15,000 | 1.00 |

| Liquid glucose | 30,000 | 0.90-0.95 |

| Dextrose (monohydrous) | 12,000 | 1.75 |

| Dextrose (anhydrous) | 100 | 0.50 |

| Sorbitol | 28,000 | 1.20 |

The seasoning industry

Thailand has three seasoning factories, one of which uses cassava starch and the other two molasses as raw material for processing MSG. MSG and lysine products are expected to be in high demand in the future, especially from food-processing industries, for both local and export markets. Lysine processing, a new industry, has raised the consumption of cassava starch in the last few years. In manufacturing MSG, cassava starch is hydrolyzed by using α-amylase enzyme and α-amyloglucosidase to change starch into glucose. The fermentation is then continued with bacteria Micrococcus glutamicus or Brevibacterium spp., which are given urea as nutrient supplement. Eventually, crystalline MSG is formed. The process was first developed in Japan, imported to Thailand, and promoted within the local food industry.

The sweetening industry Thailand first processed glucose syrup in 1950, glucose powder in 1976, and sorbitol in 1980. In 1989, the total sweetening industry consisted of seven factories: four producing glucose syrup, one producing sorbitol, and the remaining two, various sweetening products (Sathetkeingkai, 1989).

At present, the country’s production of glucose syrup is about 76,000 t, which is sufficient for local needs. Considering the potential uses of glucose syrup, it could be used in the confectionery industry, which would add value to cassava starch by as much as 55%. The consumption of confectionery products is still low, and needs to be developed and promoted both locally and regionally.

Glucose syrup can be processed in various ways. At present, a continuous process is being developed to replace the batch process by using several types of reactors for starch digestion. This process, however, requires new equipment (such as a digestion tank, filter technique, and evaporator), which needs to be designed and developed.

Sweetening products also need to be developed and their use promoted in various food industries that manufacture, for example, soft drinks, beverages, ice creams, canned foods, and bakery products. Because of severe competition with the sugarcane industry, food-processing industries are slow to develop sweeteners from starches, including cassava starch.

Conclusions

Because cassava production is predicted to increase during the next decade, research and development are needed on cassava use, for both local and overseas markets. The Cassava Development Institute Foundation has been established to study the nature of the crop’s production, use, and marketing. At present, cassava is still faced with falling prices, which affect growers, industries, and traders. Animal feed and nonfood products can also be developed as the market requires, thus adding value to the crop.