Maltodextrin (DE 15-25) produced from liquefied starch is commercially valuable for its rheological properties. Maltodextrins are used in the food industry as fillers, stabilizers, thickeners, pastes, and glues. When saccharified by further hydrolysis using amyloglucosidase or fungal α-amylase a variety of sweeteners can be produced, having dextrose equivalents in the ranges 40-45 (maltose), 50-55 (high maltose) and 55-70 (high conversion syrup) (Reichelt, 1983). Applying a series of enzymes including β-amylase, glucoamylase and pullulanase as debranching enzymes, intermediate-level conversion syrups having maltose contents close to 80% can be produced (Norman, 1982).

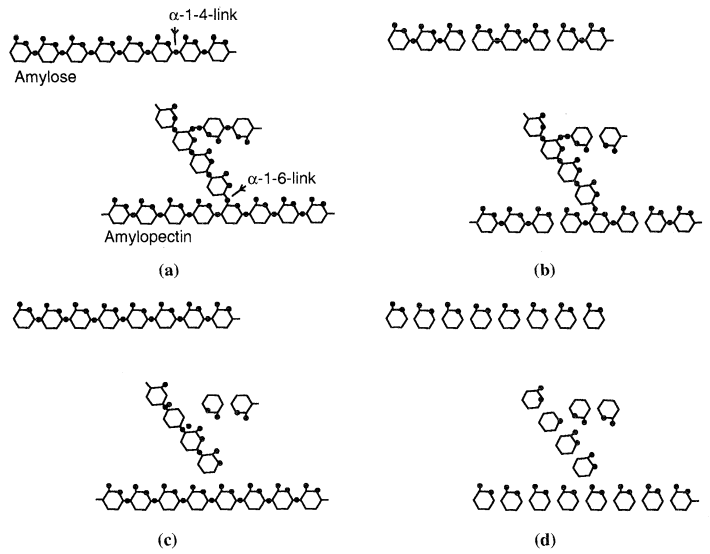

A high content of glucose (95-97%) may be produced from most starch raw materials (corn, wheat, potatoes, tapioca, barley, and rice). The action of amylases and deb ranching enzymes is shown in Figure 2.3.

Use of maltose syrups

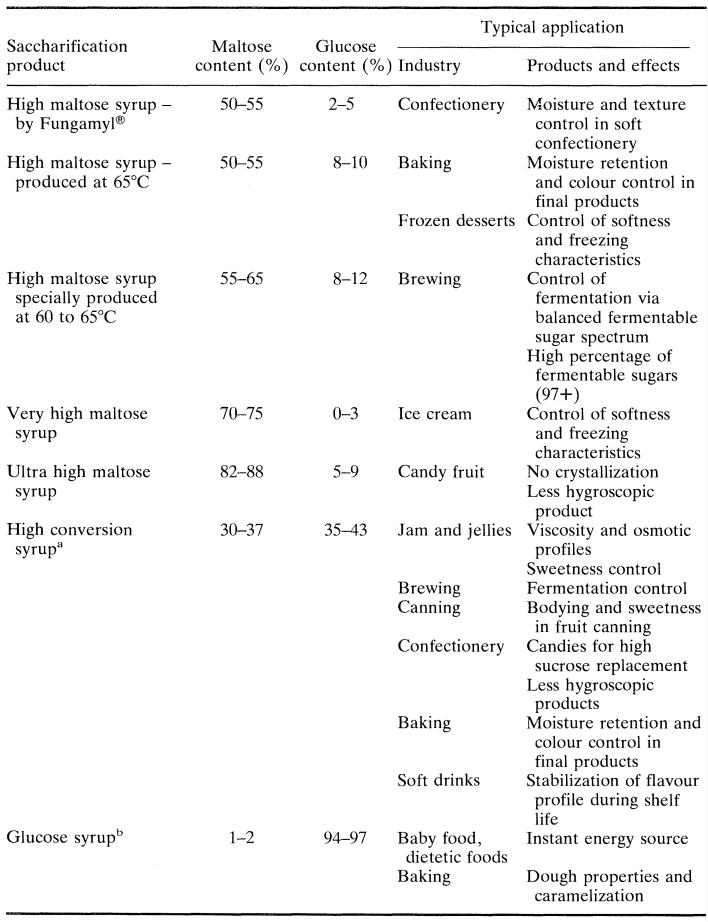

Maltose syrups are characterized by having a low content of glucose and a high content of maltose. Because of the low content of glucose, high maltose syrups show a low tendency to crystallize and they are relatively non-hygroscopic. Various specifications (maltose and glucose content) of saccharification products and some applications of maltose syrups are shown in Table 2.4

a High conversion syrups should be stable enough to resist crystallization at temperatures above 4°C and 80-83% DS. The content of glucose in these syrups should therefore not exceed 43% on DS basis.

b Apart from the food industry, syrups and crystalline glucose (dextrose) also have applications in the pharmaceutical and chemical industry.

Production of maltose syrups

Maltose syrups are produced by saccharifying liquefied starch with maltogenic exo-enzymes. Enzymes for this purpose are fungal α-amylase (e.g. Fungamyl, Maltogenase, Promozyme) or barley β-amylase (e.g. SpezymeBBA). Saccharification is conducted at 55-65°C, pH 4.8-5.5, and at a solids level DS 30-40%. The sugar spectrum obtained depends on the enzyme dosage and on the reaction time. The enzyme dosage may be in the range of 0.3-3 kg enzyme products per ton of starch (DS) and the reaction time may be in the range of 20-42 h. In the following examples, saccharification systems and reaction conditions are shown for the various maltose syrups mentioned in Table 2.4. The influence of reaction parameters on the composition of the syrups is illustrated by graphs, bar diagrams and carbohydrate spectra. All these data are from the enzyme development laboratories and pilot plant at Novo Nordisk A/S.

High maltose syrup-by Fungamyl®

High maltose syrups are produced by saccharifying enzyme-liquefied starch (DE 10-20 may be used) with Fungamyl 800L. The process should be carried out at 55°C and pH 5.5. It is important that the pH does not drop below pH 5, as the stability of Fungamyl is poor at lower pH values. Starch, dextrins and oligosaccharides have a stabilizing effect on the enzyme.

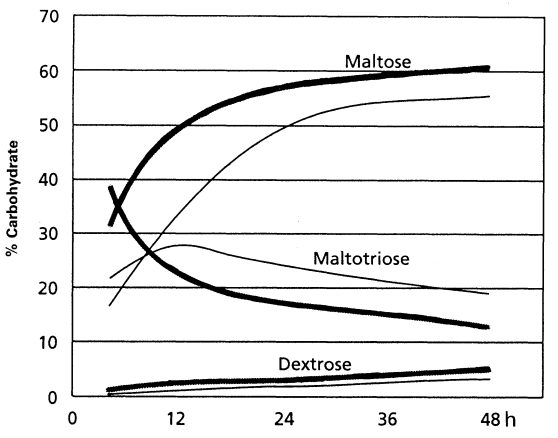

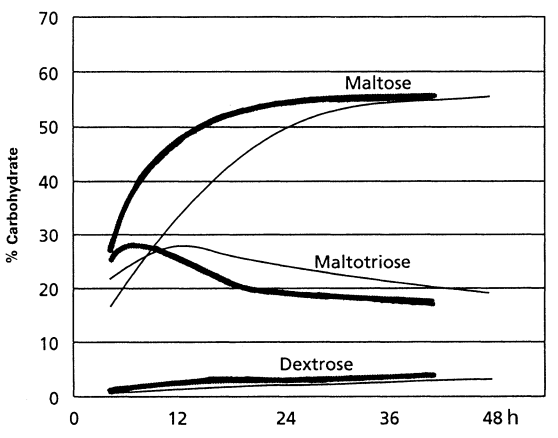

Saccharification with Fungamyl is normally carried out at 30-40% DS, and no adjustment of the dry substance concentration after liquefaction is necessary. Calcium ions also stabilize Fungamyl. Satisfactory stability is achieved at about 50 ppm Ca2+. Figure 2.4 shows the effect of two dosages (0.2 kg/t DS and 0.4 kg/t DS) of Fungamyl 800L and Figure 2.5 shows the effect of the temperature. The highly significant effect of the two reaction parameters on the composition of the syrup demonstrates the importance of being able to analyse and control the reaction while it is going on.

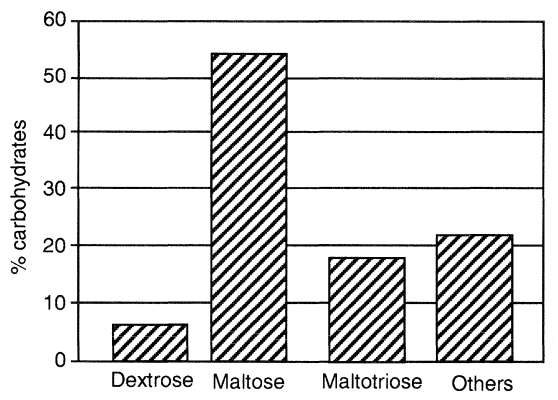

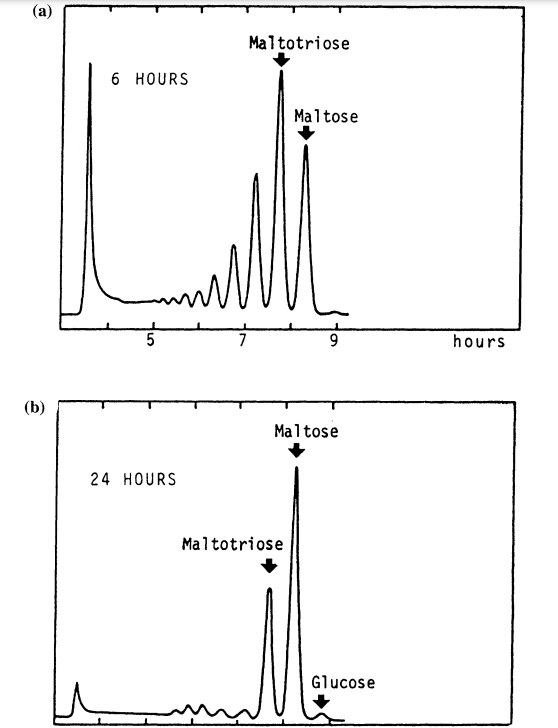

Figure 2.6 shows one example of the composition of a saccharification carried out by use of 400 g Fungamyl 800Llt DS. Figures 2.7(a) and (b) show the carbohydrate spectra of starch hydrolysed by Fungamyl for 6 and 24 h, respectively. Initially, large amounts of maltotriose are formed, but as the hydrolysis proceeds the level of maltose increases. The normal saccharification time is 24-48 h. It is usually not necessary to inactivate the enzyme after saccharification as the reaction is self terminating.

After saccharification, the syrup is filtered and refined by means of activated carbon and, if desired, demineralized by ion exchange and finally concentrated by evaporation,

High maltose syrup produced at 65oC

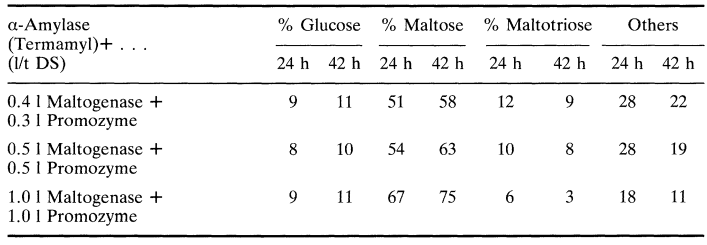

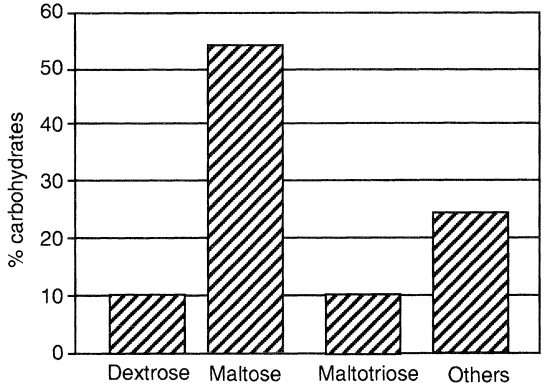

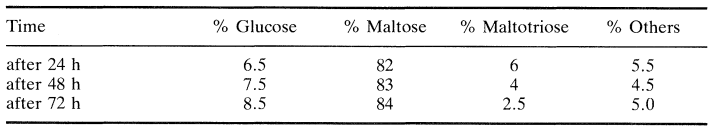

A way to increase the maltose content and at the same time reduce the content of maltotriose is to use an unconventional combination of enzymes containing 0.4 kg Termamyl 120Llt DS and Maltogenase and Promozyme in varying doses. The process should be carried out at 65°C and pH 5.0. The carbohydrate spectrum varies according to the reaction time and the level of addition of enzymes as shown in Table 2.5 and Figure 2.8.

High maltose syrup specially produced at 60 to 65°C

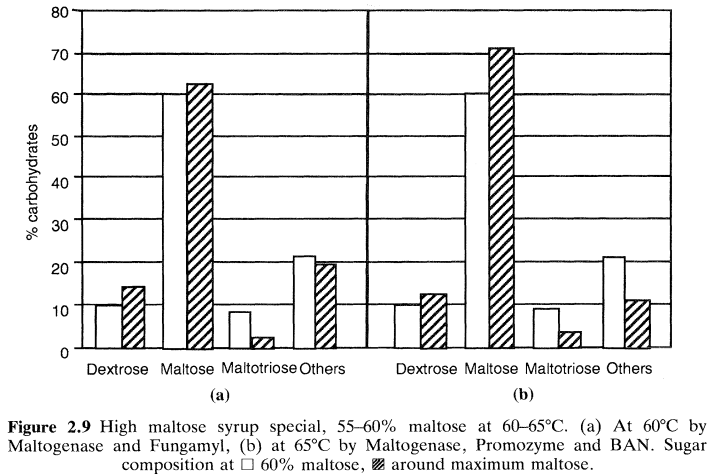

These brewing syrups can be characterized by 55-65% maltose content and a low content of maltotriose and some glucose. The enzyme-liquefied starch (DE 10-20) can be hydrolyzed at 60°C, pH 6 using Maltogenase (0.25-1.0 lit DS) + Fungamyl (0.4–1.0 kg/t DS), or at 65°C, pH 5 using Maltogenase (0.5-1.0 l/t DS) + Promozyme (0.5-1.0 l/t DS) + 0.25 kg/t DS BAN 240L to all. For BAN, see α-Amylases. Carbohydrate compositions are shown in Figure 2.9.

Very high maltose syrup

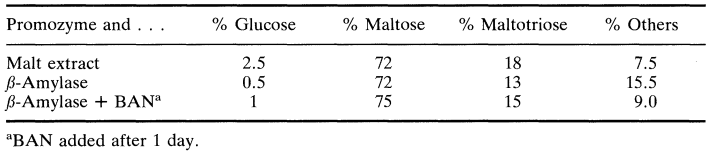

An extremely low glucose content can be secured by use of malt extract, approx. 400° Lintner (3-4 kg/t DS) or β-amylase 1500oLintner (1 kg/t DS) + Promozyme 600L (1 l/t DS). An addition of BAN to the fl-amylase saccharification after reaction for one day increases the maltose content. Furthermore, it improves the filterability of the syrup.

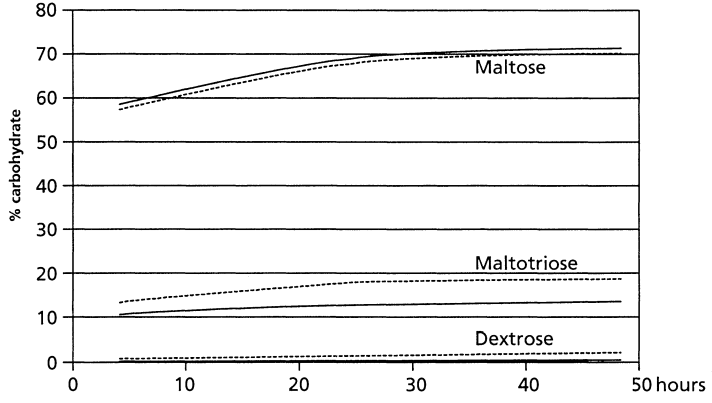

The DE after liquefaction influences the final amount of maltose; the higher the DE, the lower percentage of maltose. So, in this case certain constraints are set for the reaction parameters in order to obtain the very high maltose level. The enzyme-liquefied starch must have a maximum DE of 10, at DS = 30%. The temperature must be adjusted to 58°C and pH to 5.5. The composition shown in Table 2.6 will thus be obtained after 2 days. The time course of the saccharification is shown in Figure 2.10, and it can be seen that the increase in percentage maltose is minimal after 30 h.

Ultra high maltose syrup

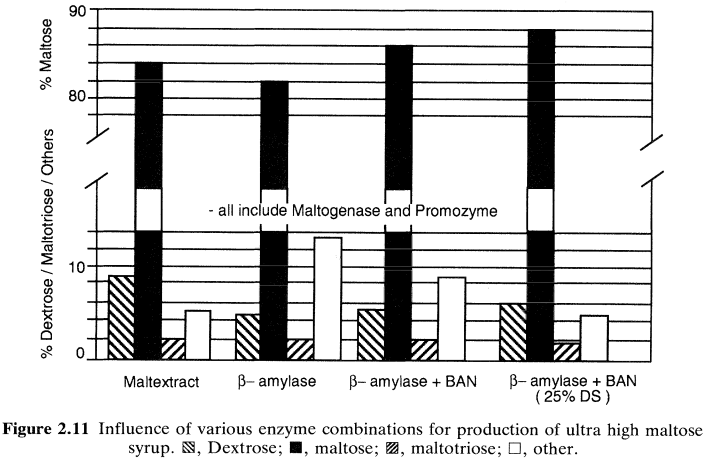

The procedure for manufacture of ultra high maltose syrups requires, as above, that the enzyme-liquefied starch has a maximum DE of 10, at DS = 30%. The temperature must also be adjusted to 58°C and pH to 5.5. These syrups are characterized by having an ultra low content of maltotriose and, as indicated, an ultra high content of maltose. In fact these syrups have the highest maltose content seen for enzymatically produced sugars. The enzyme systems used are Maltogenase (1.5 l/t DS) + Promozyme (1.0 l/t DS) + malt extract (1 kg/t DS). If malt extract is replaced by β-amylase, the maltose content will be around 2% lower. This can, however, be more than counteracted by the addition of BAN, so that the final maltose content will be 1 to 2% higher than the figures shown in Table 2.7. In Figure 2.11 the influence of various enzyme combinations, using the above mentioned enzyme products, are shown.

High conversion syrup

High conversion syrups are produced from enzyme-liquefied starch or from acid-liquefied starch by using a combination of Fungamyl 800L and AMG 200L. Higher maltose and lower glucose levels are obtained with enzyme-liquefied starch. The following conditions can be used for the production of high conversion syrups.

The process may be carried out at 55°C and pH 5.0. The dry substance should be in the range 30-40% and no adjustment of dry substance concentration after liquefaction is, therefore, necessary. The saccharification time is normally about 40 h, but shorter or longer reaction times may be used with proportionally higher or lower enzyme doses.

It is very important to inactivate the AMG when the required DE and sugar composition have been reached. If the reaction is allowed to proceed more glucose will be produced, which crystallizes when the syrup is concentrated and stored. The reaction may be stopped by heating the syrup to 80°C for about 40 min or to 85°C for about 5 min. The syrup is then filtered, carbon treated and, if desired, ion exchanged.

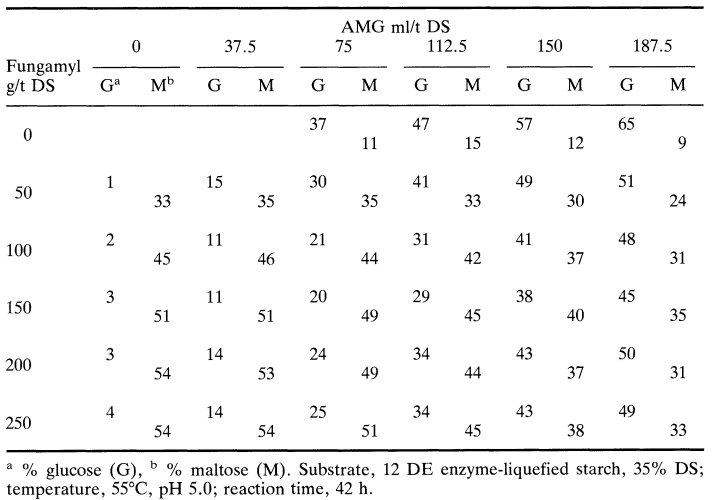

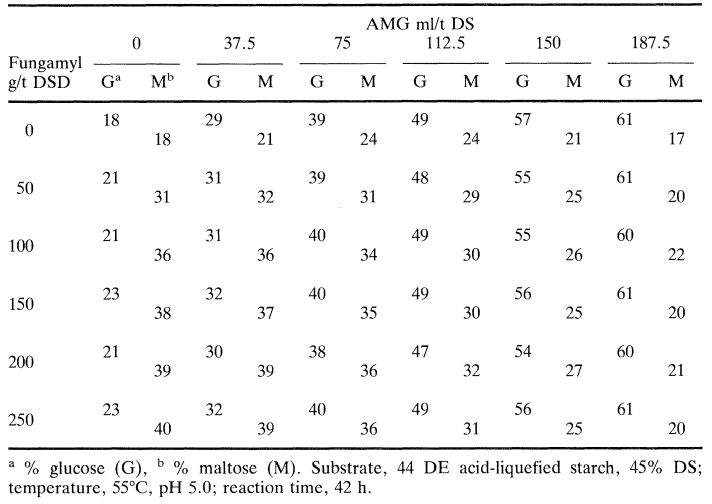

The sugar composition of the final syrup may be altered by adjusting the ratio between the Fungamyl and the AMG dosages as shown in Table 2.8 for enzyme-liquefied starch and in Table 2.9 for acid-liquefied starch. As an example the ‘standard’ high conversion syrup with 41% glucose and 37% maltose can be obtained from enzyme-liquefied starch with 100 g Fungamyl 800L and 150 ml AMG 200L/t DS. Further, the tables show that at a constant Fungamyl dosage, DE and glucose levels increase with increasing AMG dosage, while the maltose content tends to decrease. At a constant AMG dosage, DE and glucose contents are almost constant with increasing Fungamyl dosage, while the maltose content increases until it reaches a maximum at a dosage of 150-200 g/t DS.

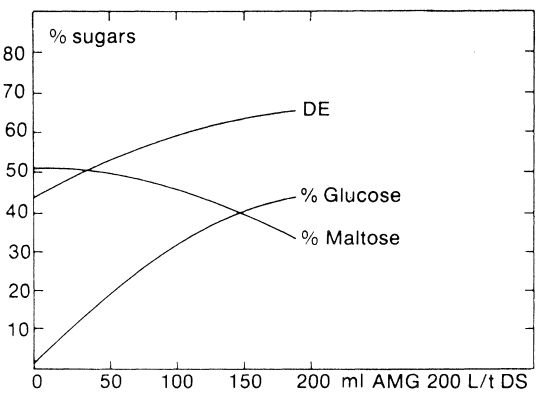

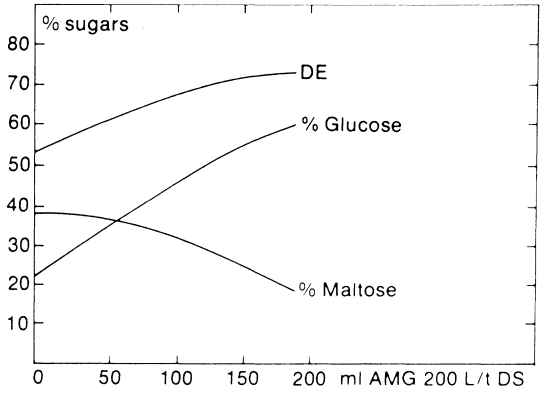

Figures 2.12 and 2.13 show DE, % glucose and % maltose as functions of AMG dosage at a constant Fungamyl dosage of 150 glt DS using enzyme or acid-liquefied starch as starting material, respectively.