Before 1985, the only cassava processing technology known in Ecuador was mechanical rasping and hand-sieving to extract starch from the roots. Since then, new technologies have been introduced, and existing ones improved, to increase processing efficiency and open new markets for both cassava starch and flour.

These new technologies include chipping, drying, and grinding cassava roots to produce meal and flour from peeled cassava roots, and sieving coarse-grained flours to produce fine ones. Improved equipment for starch processing include raspers with saws, continuous flow washer-peelers, vibrating screens, and sedimentation channels.

In Manabí, Ecuador, a participatory approach has been used to facilitate the adoption of improved technologies. The first step was to train the technical team of the Unión de Asociaciones de Trabajadores Agrícolas, Productores y Procesadores de Yuca (UATAPPY). This team copied and adapted some prototype equipment and tools on-site in the Association’s processing plants. The products—cassava starch and flour— were efficiently produced and entered national and international markets.

Flour Processing

Technology introduced from Colombia

In late 1985, trials showed that cassava meal could be technically and economically produced, using a technology introduced from CIAT, Colombia. The technology consisted of chipping, drying, and grinding dried cassava. Chips, produced by a Thai-type, mechanical, disc chipper, are dried on outdoor concrete floors and then ground in hammer mills.

Technology currently used by UATAPPY

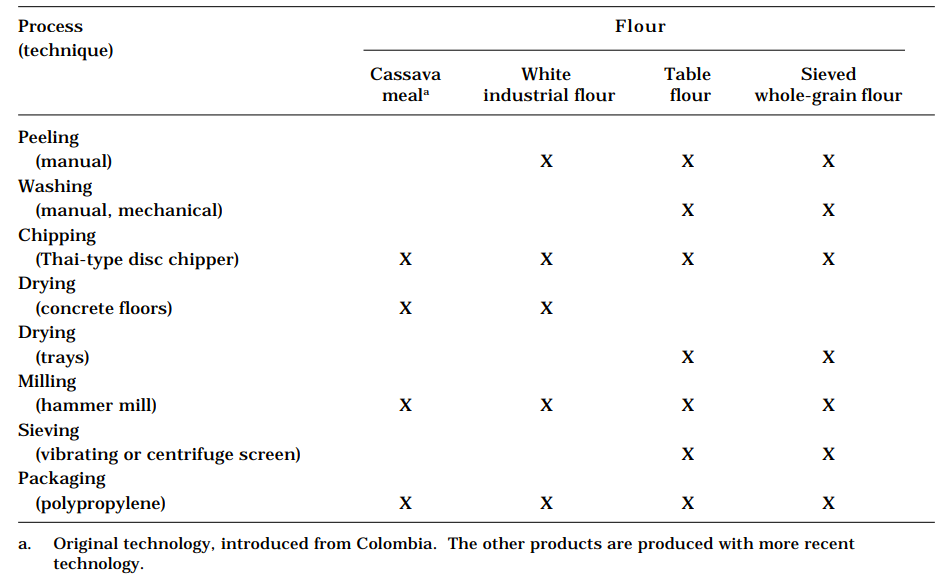

In addition to cassava meal, three other types of flour are produced: white industrial flour, table flour, and sieved whole-grain flour. The technology used to produce these flours differs from that for cassava meal (Table 1). To produce white industrial flour, the roots are peeled by hand before being fed to the chipper. The rest of the process is the same as for cassava meal. To produce table flour, the roots are peeled and washed before chipping, and then dried naturally on trays, or artificially. Once the dried chips are ground, the resulting flour is sieved through a vibrating or centrifuge screen. Sieved whole-grain flour is produced by passing the meal through a vibrating screen as for table flour.

Starch Processing

Traditional technology used in Ecuador

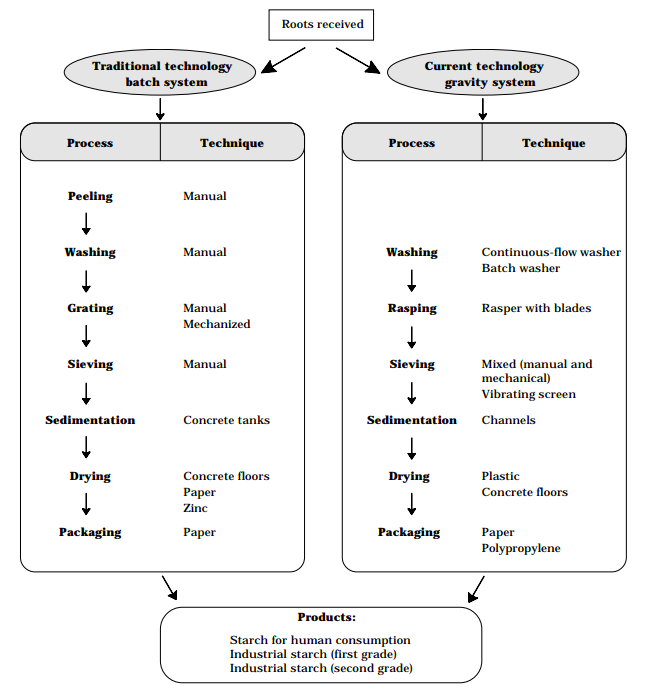

Manual starch extraction in Ecuador dates back about 50 years. Traditionally, to extract cassava starch, roots are peeled and washed by hand, grated by hand or mechanically with an engine-driven wooden drum covered with a perforated zinc plate, then sieved by hand. Sedimentation is carried out in wooden or concrete tanks, and the starch dried on concrete floors or on paper (Figure 1).

Technology currently used by UATAPPY

The UATAPPY is currently extracting cassava starch with mechanized technology developed with the technical assistance of CIAT and the Fundación Adelanto Comunitario (FACE), and with the financial support of the Fundación para el Desarrollo Agropecuario (FUNDAGRO). Cassava roots undergo the following procedures: washing and peeling, in either batch or continuous flow, with Brazilian-type washers; mechanical rasping with Brazilian-type saw blades; sieving, both by hand and vibrating screens; and sedimentation in concrete channels lined with ceramic tiles. Drying is carried out naturally on plastic sheets placed on bamboo platforms. When a finer quality product is required, milling is done in hammer mills (Figure 1).

Experiments

Sour starch production trials were first carried out in December 1992 and renewed in November 1993 at two starch factories, both UATAPPY members. Artificial drying trials with a flash dryer will be conducted, together with mechanized sieving, using vibrating or centrifuge screens.

Training and Institutional Support

To introduce and adapt new cassava processing technologies, especially for starch, UATAPPY received technical and financial support from FUNDAGRO and CIAT. Its technical team has received training nationally and in Colombia and Brazil on elements of processing and technology.

Results

- Product quality (flours and starch) has improved, allowing new markets to be opened at national and international levels.

- Higher yields have been obtained and efficiency has improved.

- Production capacity, especially of starch, has increased.