CIAT has developed a strategy to design and implement cassava projects, integrating aspects of the crop’s production, processing, and commercialization in northern Colombia. Within this framework, three phases of development can be distinguished:

(1) Research: developing technology for cassava processing, and studying in detail the technology’s market opportunities, both on a national and regional basis. (2) Pilot project or market test: producing and marketing on a small scale under real market conditions. (3) Commercialization or expansion: consolidating the market for new products and replicating the processing units.

A project to develop, under this strategy, a rural cassava flour industry was begun, and its progress so far is reported here.

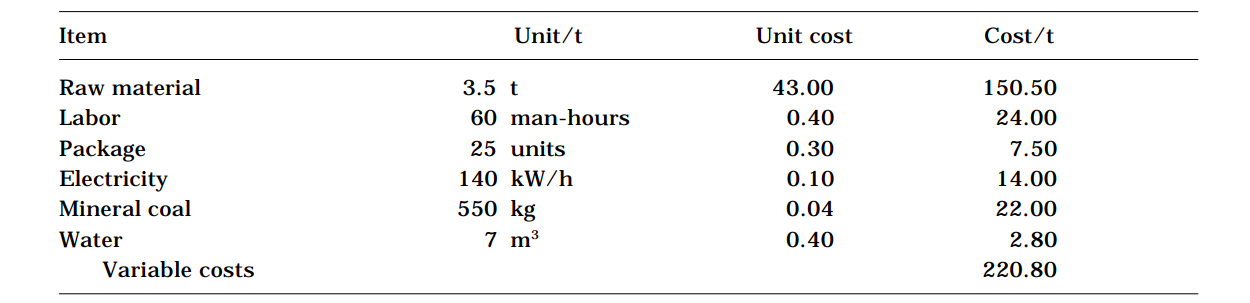

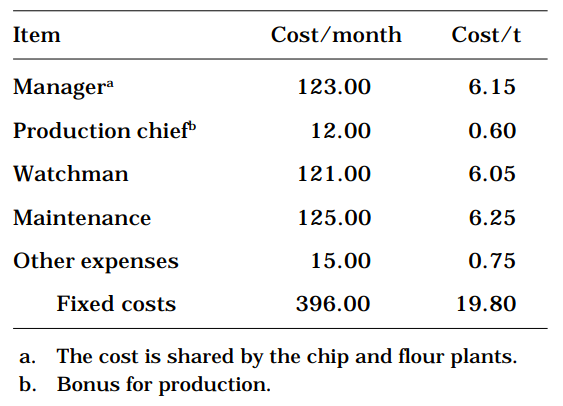

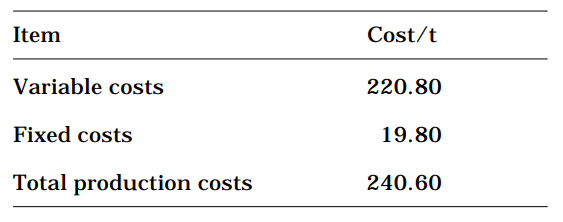

Results of phase I (research) indicated that, under the cost and price structures of cassava and wheat in Colombia, producing cassava flour at a price competitive with that of wheat flour was economically feasible (Tables 1, 2, and 3). Hence, the next phase, that of the pilot-project, was initiated.

In the research phase, baked products had been considered as the main market, where cassava flour would substitute 15% of wheat flour. But, because bakers saw a high risk of decreased product quality when using cassava flour, phase II was focused on other food categories where cassava flour would not present high risks.

With phase II, the production, processing, and marketing components of the cassava flour system were integrated under the real conditions of a cassava-growing region in Colombia. These results can be used by both public and private enterprises to promote the replication of rural, cassava flour-producing plants and the product’s use in the national food industry.

The institutions participating in the project are CIAT, Cali; Universidad del Valle, Cali; the Fondo de Desarrollo Rural Integrado (DRI) of the Colombian Ministry of Agriculture; and the Fundación para la Investigación y el Desarrollo de Tecnologías Apropiadas al Agro (FUNDIAGRO). The donor agency is the International Development Research Centre (IDRC), Canada.

Methodology Used in the Integrated Cassava Project

The integrated cassava project is a rural development strategy. It is carried out by small-scale, rural producers and inhabitants. It is implemented in three phases, and promotes cassava’s transformation in agroindustry by integrating functions of production, processing, and commercialization. It is supported by governmental and nongovernmental organizations.

Phase I of the Flour Project: Research (1985-1987)

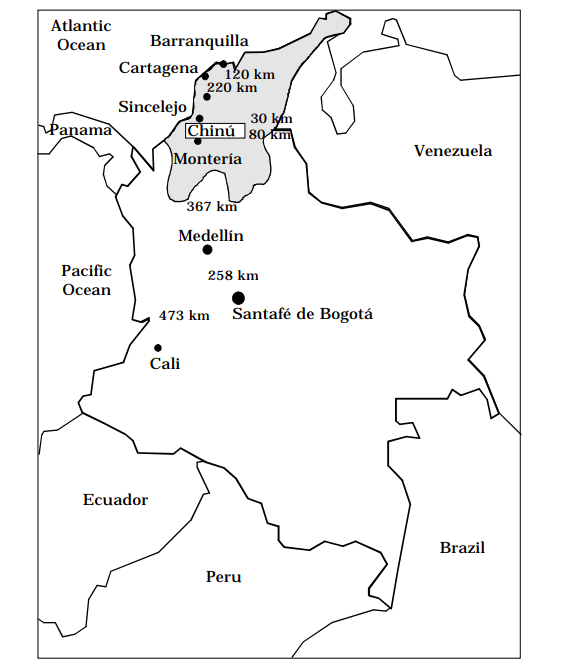

Colombia’s economic situation, the prospects for cassava, and the national potential for cassava-based products were studied to select the most promising product and choose an appropriate site. The Atlantic coastal region (northern Colombia) was also studied as having the greatest potential for developing the project. Aspects such as cassava production, farmer organizations, and markets were taken into account to choose the best site for the pilot plant.

Aim

The objective of this phase was to determine the economic and technical conditions required for the project.

Activities

Studies were made of the cassava production and marketing systems on Colombia’s Atlantic coast. On-farm trials were conducted with improved cassava production technology. Economic studies were made of the wheat milling and baking industries. The experimental cassava flour plant was designed and developed. Trials were made of equipment and processing. Laboratory trials were made on flour quality and consumer acceptance.

Results

The results demonstrated the technical and economic feasibility of producing cassava flour to compete with wheat flour in Colombia.

Phase II: Pilot Project (1988-1992)

A pilot plant was set up in Chinú, Department of Córdoba (Figure 1), with technical conditions for semicommercial operation under real market conditions.

Aims

The major objective was to validate the technology under real field conditions, integrating production, processing, and marketing. Other objectives were to (1) gather reliable data on production costs and on the investment needed to establish this type of plant; (2) produce enough cassava flour to promote its use among consumers; and (3) use the plant as a display model to expand this technology to other regions of Colombia.

Activities

The main activity was to establish the pilot plant. Criteria for site selection included aspects of cassava production, land availability, potential for increasing cassava yields, processing, raw material availability (production, seasonality, access to fresh market), service infrastructure (water, electricity, roads), proximity to terminal markets, institutional presence and support, potential project impact, and socioeconomic importance of cassava.

Alternative sites were surveyed, four potential zones selected, then a site, with farmer organizations close by, was chosen. The pilot plant was redesigned, in which combined natural and artificial drying was eliminated. A designer and builder were contracted and the redesigned plant built.

Results

The pilot plant began operating with adjustments in production, processing, and marketing. A viable and functional model was obtained.

Phase III: Commercial Expansion (1993 Onward)

A market study for the new product was designed and developed, clients were contacted, and test trials conducted with them. Commercializing cassava flour in the meat processing and adhesive industries began.

At the time of writing, project expansion to other areas of Colombia had not yet started, market expansion was still to come, together with a further consolidation of the new rural agroindustry.

Aim

The objective was to market cassava flour and consolidate a rural agroindustry that would benefit farmers, not only in northern Colombia, but also in other regions.

Activities

A marketing plan was designed and executed, and market segments selected. A bibliographical review was made of cassava flour uses. Commercial contacts were established and sales volume and conditions determined.

Results

Commercialization of cassava flour has begun. The model has been evaluated and adjusted and new sites selected. The project is expanding to other zones.

A Cooperative Carries Out

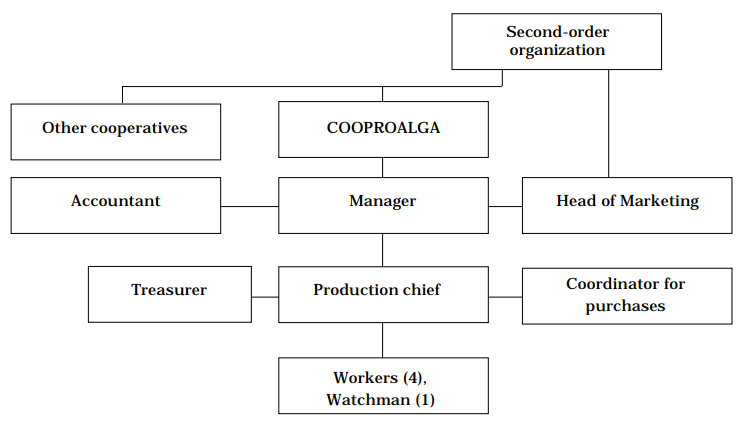

the Project The Cooperativa de Productores de los Algarrobos (COOPROALGA), based in Chinú, is a first-order organization with 43 members, all small-scale farmers dedicated to growing cassava intercropped with maize or yam. Most members pay rent for land and the remaining 20% own it.

COOPROALGA manages two plants, one producing cassava chips for animal feed, and the other the pilot cassava flour plant (Figure 2).

Characteristics of the Plant, Process, and Product

The flour plant

The cassava flour plant is a warehouse with an office, bathrooms, a tool room, a coal storage room, and areas where cassava roots are received, washed, chipped, and dried. The ground area of the plant is 2,058 m2.

The plant has two water storage tanks, one underground with a capacity of 39 m3 and the other elevated, holding 6 m3. All the plant’s residual waters flow in two independent lines. The plant’s walls are of concrete blocks, and the roof has a metal framework and is tiled with asbestos.

Construction of the plant had cost US$29,484.00 in March 1990. The Universidad del Valle and CIAT designed the main processing equipment, which was built in Cali.

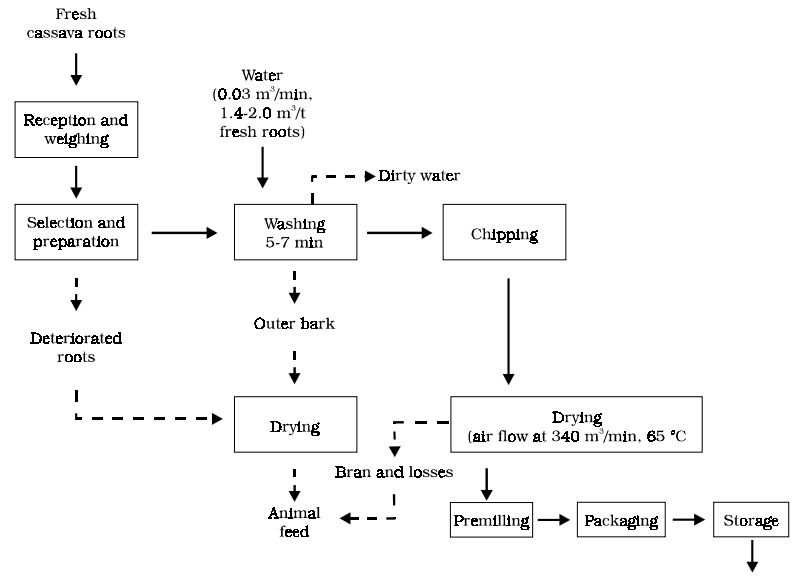

Processing

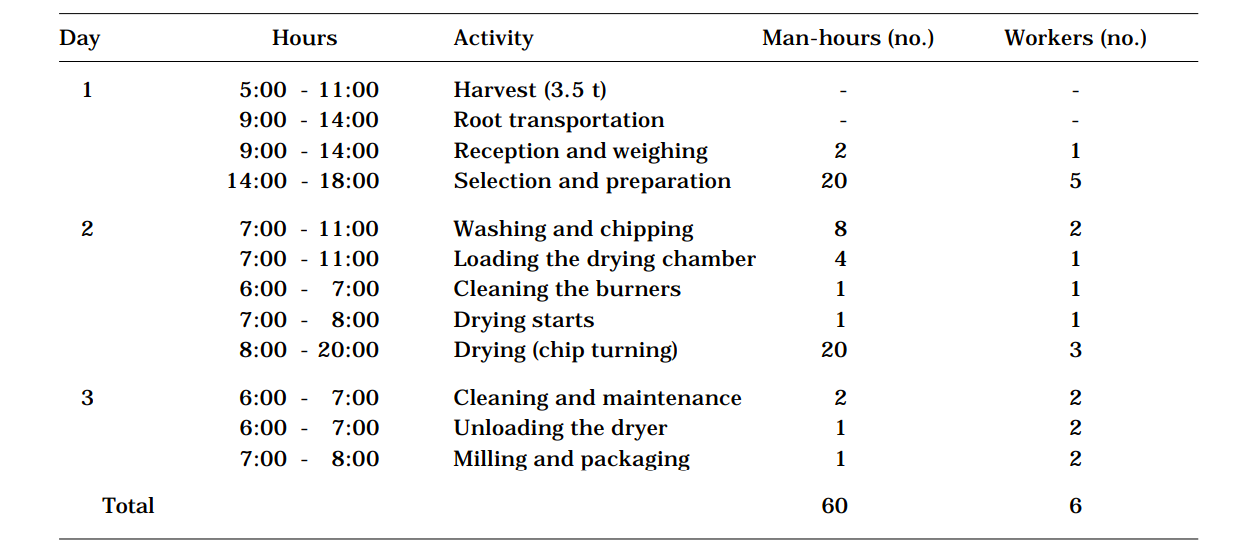

A batch process was implemented and includes the following operations: harvest, transport, reception, weighing, selecting, preparing, washing, chipping, drying, premilling, and milling. The resulting cassava flour is then packaged and stored (Table 4 and Figure 3).

Each batch is processed in 2 days. On the first day, the roots are harvested, transported, selected, and prepared. On the second day, they are washed, chipped, dried, and milled, and the resulting flour stored.

The product

Before harvesting, the farmer prunes the cassava plant, removing aerial parts, and on the next day he harvests and packs the roots, and takes them to the plant.

Cassava roots are received in 50 to 60 kg sacks, and should have been harvested on the day of receipt. They should also be free of diseases, deterioration, or severe mechanical damage, and should be from varieties containing high dry matter content.

After washing, chipping, drying, milling, and sieving through 150 microscreens, cassava flour is finally obtained.