Cassava (Manihot esculenta Crantz) is an important food staple for about 500 million people of the tropical world (Cock, 1985). Cassava roots are processed by several traditional methods, which vary widely from region to region. Usually, these techniques are intended to reduce the level of cyanogenic glucosides in the roots and improve palatability and shelf life of the resultant products (Cooke and Maduagwu, 1978). While fermented food products from cassava are popular in many African countries, preparations from dehydrated flour and those from cooked fresh roots are preferred in Asian and many Latin American countries.

Yuca rava and porridge are two novel food products made from cassava roots at the Central Tuber Crops Research Institute (CTCRI), Trivandrum, India. These products are likely to capture the Indian food market because of the ease and relative economy of their preparation (Balagopalan et al., 1988). Before being promoted in potential markets, these two products were evaluated for their quality, rheological and pasting behavior, and residual cyanogen contents. The results are reported in this paper.

Materials and Methods

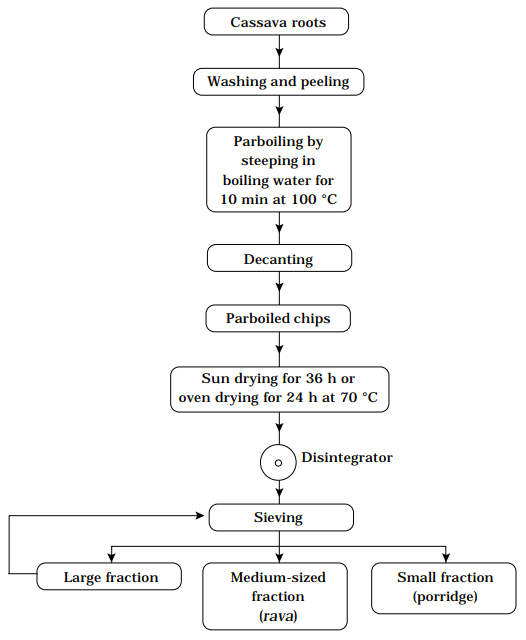

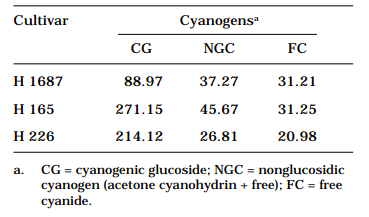

Yuca rava and porridge were prepared (Figure 1) from three cassava varieties: the low-cyanogen cultivar H 1687; and two high-cyanogen cultivars, H 165 and H 226 (Table 1). Normally, varieties requiring less cooking are preferred for preparing rava and porridge as the starch in the roots does not gelatinize completely within the 10-min cooking time. This technique of partial gelatinization, or parboiling, helps in the partial swelling of starch granules. The dried, parboiled chips are powdered to obtain the finer fraction called “porridge” and the coarse fraction called rava.

Conventionally, rava is prepared from round cassava chips which are put into boiling water. An attempt was made to find out whether cyanogen retention in parboiled chips could be reduced with a smaller chip size. The round chips (1 cm thick) were either quartered to equal portions or cut into strips of uniform width before being used to make rava and porridge.

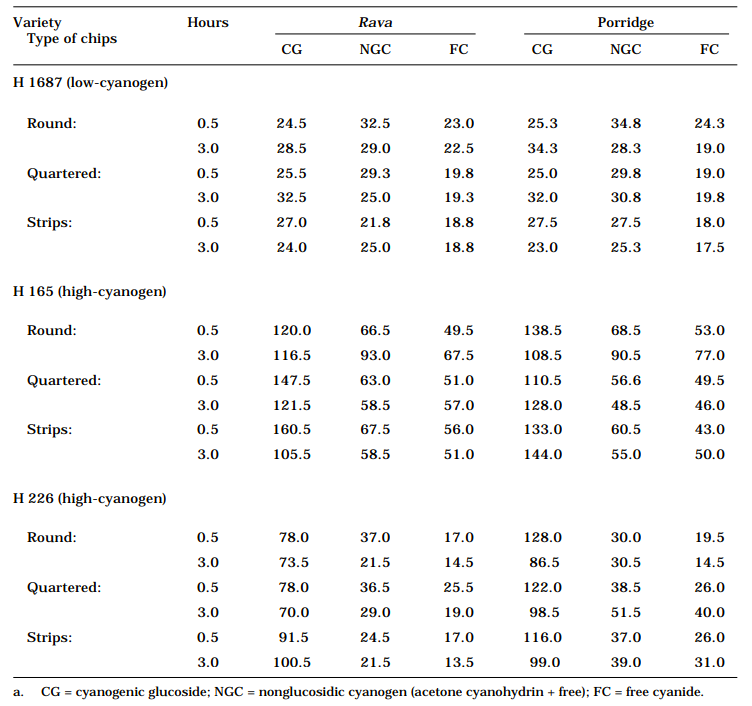

A parallel study was undertaken to find out whether an initial presoaking of cassava chips for varying periods helps remove cyanogens from the roots. Round and quartered chips, as well as strips, were soaked for 30 min, 1 h, 2 h, or 3 h in standing water (1:4 w/v), then the water was drained off. Rava and porridge were prepared from these chips as normal.

The total and intermediate (nonglucosidic, i.e., acetone cyanohydrin, plus free) cyanogens, and free cyanide were quantified in the rava and porridge prepared from the three cultivars. The methods for extraction and initial stages of cyanogen determination up to the formation of cyanogen chloride were adopted from O‘Brien et al. (1991). The coupling of cyanogen chloride was done with the barbituric acid pyridine reagents used in the Nambisan and Sundaresan (1984) procedure.

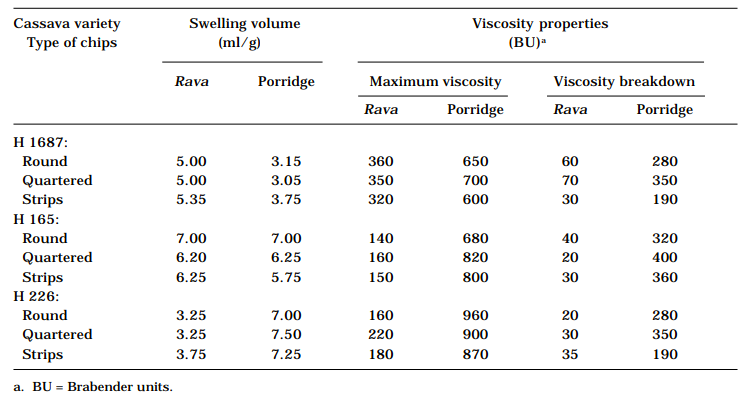

The viscographic behavior of rava and porridge samples from the three cultivars was studied with a Brabender viscoamylograph. A concentration of 10%-20% by weight of sample was studied at a heating rate of 1.5 °C per minute. The peak viscosity at 97 °C and viscosity after cooling were recorded. The swelling volumes were determined by standard procedure (Schoch, 1964). A sample of 400 mg rava or porridge was suspended in 40 ml water, heated to 95 °C, maintained at that temperature for 15 min, then cooled and centrifuged at 2,200 rpm for 15 min. The volume of the gelatinous precipitate obtained was taken as the swelling volume.

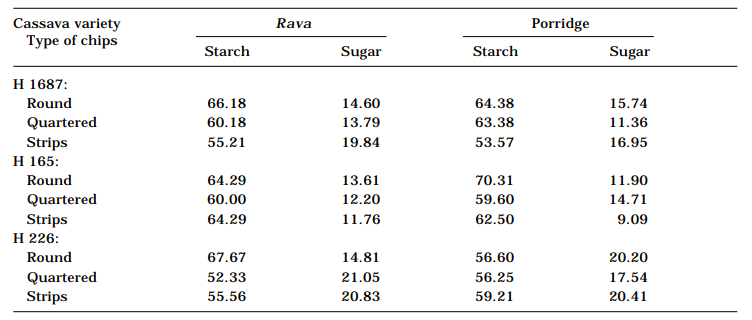

Starch and sugar contents of rava and porridge were determined by a standard titrimetric procedure (S. N. Moorthy, personal communication). Using 80% alcohol, sugars were extracted from samples by standing overnight. The remaining residue was hydrolyzed with 2N HCl to convert starch to sugars. These released sugars were quantified through ferricyanide titration (S. N. Moorthy, personal communication) and the starch value computed, using a factor of 0.9.

Results and Discussion

Of the cassava-consuming areas of the world, India is perhaps unique in making pregelatinized, dried preparations from cassava. Yuca rava and yuca porridge are two novel products that can be easily prepared, have an acceptable shelf life, and are tasty.

Cyanogen changes

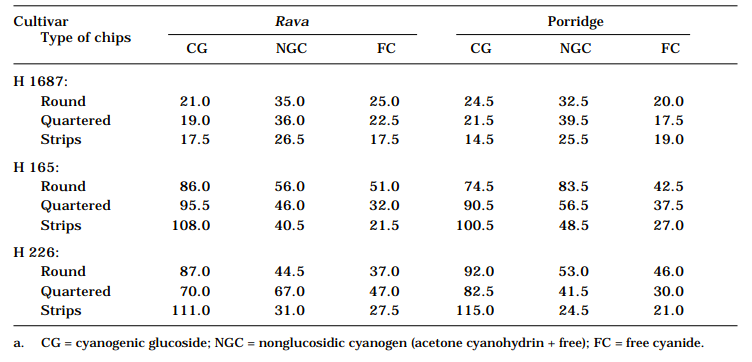

The residual cyanogenic glucosides (CG) in rava made from the low-cyanogen cassava cultivar H 1687 ranged from 17.5-21 mg/kg DM and, in porridge, from 14.5-24.5 mg/kg DM, according to the type of chips (Table 2). These ranges were much lower than those for the products made from the two high-cyanogen cultivars, H 165 and H 226. The initial CG values were much lower for H 1687 roots (88.97 mg/kg DM), compared with the high-cyanogen cultivars (Table 1).

For each variety, however, the CG content among the three types of chips (round, quartered, and strips) did not vary significantly when they were put directly into boiling water, parboiled for 10 min, dried, and powdered to make rava and porridge (Table 2). The lack of variation may be a result of the rapid loss of linamarase activity at 100 °C as the roots were directly exposed to this temperature.

The extent of cyanogen removal during the boiling of cassava roots depends on boiling time, volume of water used, and size of root piece (Padmaja, 1993). Ezeala and Okoro (1986) reported that, after 35 min of boiling, cyanogens were undetectable in the roots they used. The initial cyanogen level of 218 mg/kg had dropped to 97 mg/kg within the first 5 min of boiling. However, the authors had gradually raised the chips to boiling point, taking 20-25 min. During that time linamarase could act on the glucosides.

Cooke and Maduagwu (1978) also observed that bound cyanogen was removed at a slower rate only during boiling and 55% of it was retained after 25 min of boiling. Nambisan and Sundaresan (1985) reported that during 30 min of boiling, only 45%-48% of total cyanogen was eliminated from the roots (varieties H 165, H 2304, and H 1678).

We found that the CG content dropped from about 89 to 17-21 mg/kg DM in the low-cyanogen cultivar H 1678 during 10 min of boiling. For the high-cyanogen cultivars, reductions were from 271 to 86-108 mg/kg in H 165, and from 214 to 87-111 mg/kg in H 226.

Fukuba et al. (1984) observed that cultivar variations strongly influenced cyanogen elimination in 1-cm diced roots during boiling or soaking treatments. They compared the effect of slow with rapid boiling. They found that, while 70% of total cyanogen was eliminated from cubes brought to boiling point, only 30%-35% of total cyanogen was eliminated if chips were put into boiling water, even after 10 min of cooking at 100 °C.

Soaking the different types of cassava chips for varying periods from 30 min to 3 h in standing water did not reduce the quantity of cyanogen compared with unsoaked roots (Table 3). Nor did chip type influence cyanogen elimination during soaking. Similar trends were obtained for low- and high-cyanogen cultivars. But cultivar variations are likely to affect the cyanogen elimination during soaking. Fukuba et al. (1984) obtained 54% elimination of total cyanogen from 1-cm diced roots of variety Bogor 397 during 10 min of soaking, while only 5%-6% cyanogen was eliminated from other varieties.

The reduction in CG during the preparation of rava and porridge indicates that cyanogen hydrolysis takes place during parboiling. The free cyanide contents of the rava and porridge obtained from each variety by various techniques vary little (Tables 1 to 3). This indicates that the free cyanide formed is rapidly lost from boiling water, but that a certain amount of free cyanide is retained in dried, parboiled chips.

Rapid parboiling, by adding chips to boiling water, is insufficient to eliminate cyanogen from high-cyanogen cultivars. Rigorous processing is needed to minimize cyanogen retention in high-cyanogen cultivars. But for low-cyanogen cultivars, such as H 1687, rapid parboiling helps reduce operational costs during manufacture of food products.

Rheological and swelling properties

Table 4 shows the rheology of rava and porridge samples of the three varieties. Significant differences in swelling volumes exist among the porridge samples of the three varieties. Swelling volumes were highest for porridge made from H 226 and lowest for that from H 1687. For rava samples, H 165 had the highest values and H 226, the lowest.

No relationship was found between the shape of the chips used to prepare rava and porridge and swelling volume. The values obtained were much lower than those normally observed for corresponding starch samples which have 3-4 times the swelling volumes of rava. The lower swelling volumes can be attributed to the preliminary swelling of starch during parboiling of the chips. Most of the starch granules were already swollen during the rava preparation.

The swelling volumes observed also indicate an almost equal starch distribution in both rava and porridge samples. No significant differences in swelling volumes exist according to soaking period of chips, which was expected. Raja and Mathew (1986) observed the sedimentation volume of powdered, parboiled chips to increase slightly with longer boiling time. But we observed swelling volume to decrease with parboiling.

Viscosity data showed rava samples to have a different viscosity pattern to that of porridge samples. Porridge showed peak viscosity before 60 °C, whereas rava behaved like a starch, with a peak viscosity around 75-85 °C.

Recently, Raja and Ramakrishna (1990) found that parboiling affects viscosity properties. Earlier, Raja et al. (1982) reported that the viscosity of powdered, parboiled chips was lower compared with powdered, dried chips. This corroborates our findings.

Starch and sugar changes

No significant differences were observed in the starch content of rava and porridge samples according to cultivar. Starch content ranged from 52%-66% in the rava samples and 56%-70% in those of porridge. Neither was a relationship found between chip type and starch content of rava and porridge. Total sugar content was higher for the rava and porridge made from H 226 than from H 1687, and lowest for those from H 165. These parameters did not seem to influence the rheological or swelling properties of these food products (Table 5).

Conclusions

The rheological and swelling properties of the rava and porridge fractions made from the three cassava cultivars suggest their suitability as a wheat substitute for breakfast recipes and certain south Indian sweet dishes. However, the retention of cyanogens were found to be slightly high in the case of the high-cyanogen cultivars. We expect to study detoxifying processes in an attempt to develop suitable processing technologies for high-cyanogen cultivars, thereby increasing demand for food products made from such cultivars.