Earlier surveys revealed that cassava chipping is traditional among women in Mabagon, a cassava-growing village in the Philippines. This paper discusses the experiences gained from the pilot project conducted there to increase the women’s processing efficiency by improving cassava chip and flour processing technologies and to assess opportunities for market expansion.

An association, consisting mostly of women (16 out of 19 members), was organized and trained to operate the pilot plant and to promote and market the cassava flour produced. The pilot operation began in October, 1991. The association now produces 20-75 bags (at 20 kg/bag) of cassava flour per month. These are sold to nearby bakeries, which use the cassava flour to prepare different baked goods. Plans for a full-scale commercial expansion are already under way.

Introduction

Root crops are given high priority because of their ubiquity in upland areas, which comprise about 15%-20% of land use in the Philippines. About 500,000 small-scale and marginal farmers rely on root crops for food security and supplementary cash income. Because the traditional ways of consuming root crops are few, optimizing their uses depends on an expanded agroindustrial market. This means focusing on postproduction technology.

Studies in Asia and Africa have shown that women farmers are largely involved in postharvest activities, particularly selling and processing. Thus, the “Women in Postproduction Systems” (WIPS) Project” was conceived to improve women’s efficiency in postproduction activities and increase household incomes. This was first spearheaded by the Southeast Asian Regional Center for Graduate Study and Research in Agriculture (SEARCA), collaborating with the Philippine Root Crop Research and Training Center (PRCRTC), the National Postharvest Institute for Research and Extension (NAPHIRE), and the Isabela State University (ISU) for root crops, rice, maize, and groundnuts. Funding came from the International Development Research Centre (IDRC).

Previous surveys in the Philippines showed that women are active as farm helpers, sellers, and processors of root crops into native delicacies. An important finding was the indigenous processing of cassava into dried chips in the islands of Leyte, Bohol, and the Camotes, and Misamis Oriental Province, for feed, food, and trade. Women were largely involved. This finding provided an opportunity for intervention by the project.

A diagnostic survey of root-crop farming households in Leyte Province, and an inventory of possible technologies that could fit into local systems, helped develop the idea of introducing components of cassava flour technology (which uses dried chips) to women farmers in the area around the town of Hindang, Leyte Province. The chips made in this area are of relatively good quality for flour.

This paper serves as a methodological note on the PRCRTC’s experience in cassava flour processing and commercialization, involving mostly women. This phase, which started in October, 1991, is an integral component of the WIPS Project.

Objectives

The project has the following objectives:

- To introduce root-crop equipment that would improve the efficiency of cassava flour processing in a selected community (i.e., Mabagon village near the town of Hindang, Leyte Province).

- To test storage technology for dried chips and flour.

- To strengthen the capability of beneficiaries in organizational and entrepreneurial skills.

- To assess the effects of the introduced technologies on farming households.

Project Site and Beneficiaries

The project site is Mabagon, a village with a little more than 100 farming households, situated about 3 km to the northeast of Hindang. Copra (from coconut) and palay (from rice) are the main agricultural products of Hindang’s hinterland, But most of the lands planted to these crops are owned by a few, relatively rich, landholders.

Small-scale farmers farm the uplands, 70% of them owning the land they till. A transect showed a predominance of upland cultivation of either sequential cropping or intercropping of cassava, sweetpotato, maize, vegetables (string beans, ampalaya, eggplant), and upland rice, with patches or fringes of taro and banana.

Most men receive income by working as hired hands (planting, harvesting, threshing) in the rice fields, selling upland cash crops (such as root crops, bananas, and vegetables), and raising livestock. Most women are engaged in selling various farm products and processing cassava, on the farm, into dried chips for feed.

This mixed farming system, where indigenous cassava processing plays an important role, was a promising match for village-based, cassava-flour processing and “shovel” feed mixing from byproducts. More especially, the local system fitted the project’s particular concern for gender roles in farming systems and for improving women’s cassava postproduction activities.

The Mabagon Root Crop Association (MARCA), the core group of collaborators, consisted of 19 farmers and processors: 3 men and 16 women. It was formed after several consultations among the local people and was finalized during the general assembly in December, 1991. Membership was voluntary; interest, commitment, and availability for the groups’ activities were prerequisites. Currently, MARCA’s registration as a cooperative is in process, with all requirements already met.

Technologies

The component technologies, pilot tested for cassava flour processing, included:

- PRCRTC-developed,.village-level, cassava flour processing machines (chippers, modified tapahan dryer, grinder, and flour finisher).

- Storage for chips.

- Technology for byproduct use, that is, a neutral-scale “shovel” technology, in which cassava meal is mixed with other ingredients to produce a feed for swine.

In the initial phase of commercialization (toward the middle of the second year), expansion of market uses was explored. This led to new food-processing products technologies and, therefore, new bakery products being introduced to bakeries and to MARCA (e.g., cacharon [a puffed product with various flavors], polvoron, and processing cassava sticks and chips from fresh roots).

Methodology

The project took an integrated process approach, that is, a set of strategies was developed to coordinate needed components and was flexible enough to allow redesigning as new or improved methods were tested, refined, and disseminated through the targeted beneficiaries. This approach was essential for the project’s success at the village level, where uncertainties were common and the reaction of people to introduced innovations unknown. The project was integrated in the sense that a multidisciplinary team implemented it, coordinating the phasing of various components, both technical and socioeconomic.

This approach is characteristically systems-oriented, interdisciplinary, participatory, and oriented by users’ perspectives, local knowledge, practices, and norms.

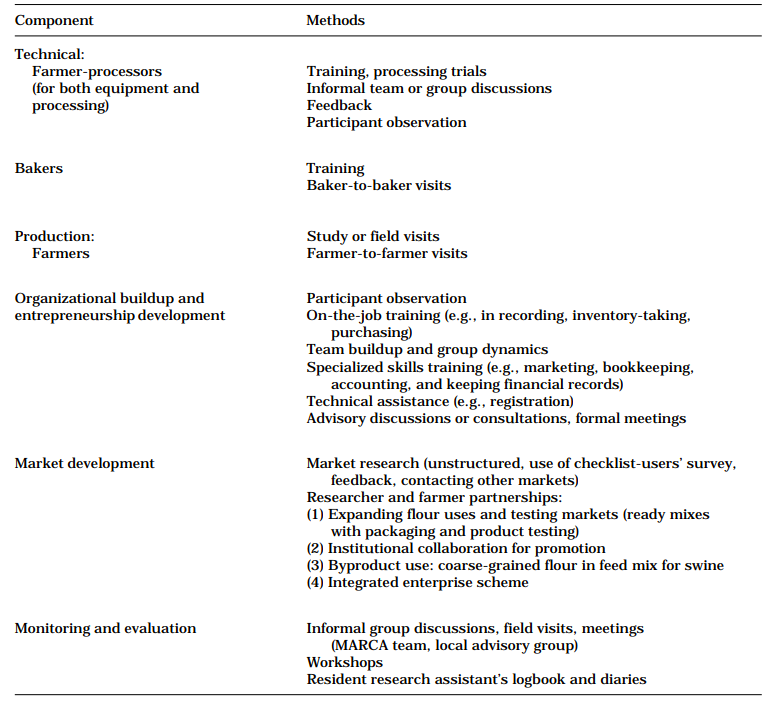

Project implementation involved carrying out activities of different components designed in a stepwise but interphased manner to effectively transfer the technology to a functioning enterprise (Table 1).

MARCA: Its Progress to Date

Registration

By consensus, MARCA was first organized as an association and registered with the Department of Labor and Employment (DOLE). This was partly because about half of the members, at first, resisted a cooperative registration, seeing a conflict of interest with an already existing cooperative in the village. Later, realizing the benefits of forming a cooperative, particularly that of obtaining funds, MARCA members voluntarily agreed to registration as a processing cooperative.

With the registration, the cooperative met the requirements to receive support from the Countrywide Development Fund (CDF) for the processing facility. The registration and fulfillment of other requisites (including articles of cooperation, constitution and bylaws, seminar, and economic survey) also brought support from the Cooperative Development Authority (CDA). MARCA also received assistance in registering with the Department of Trade and Industry (DTI), Bureau of Food and Drugs (BFAD), and a local nongovernmental organization.

Group buildup and entrepreneurial development

Building up entrepreneurial skills and strengthening the group were essential components for operational sustainability. These were carried out through:

Sessions on group dynamics. The first four sessions were designed to form values and attitudes that would condition individual members toward effective group endeavor. The remaining sessions concentrated on learning entrepreneurial skills, that is, planning, organizing, operational management, control, and evaluation.

Specialized training in entrepreneurship. Sessions were given in collaboration with the DTI. An initial, one-day, entrepreneurial appreciation session was conducted with emphasis on marketing skills. Other sessions included bookkeeping and marketing skills.

On-the-job training. During field and monitoring visits, researchers gave informal consultations and discussions on business management, marketing, recording, inventory-taking, product quality control, and equipment and facility maintenance. The resident research assistant gave a tutorial as part of the post’s responsibility.

Workshops. Two workshops were conducted at the PRCRTC in August 1992 and March 1993. They were designed as learning exercises for MARCA members in presentation and analytical evaluation. The first workshop included MARCA and the other agencies involved in the project. The second was an attempt by the PRCRTC to encourage the different pilot project collaborators, and governmental and nongovernmental agencies to interact and learn from each others’ experiences and to define their respective roles in this and other development programs.

Changes in the operational scheme

Cassava flour processing follows a decentralized operation where roots are chipped and dried to a specified quality by individual farmers, then sold to the plant. The chips are then milled and stored. MARCA distributes finished flour on a per order basis, once a week. The schedule, organization, and management of operational activities were made according to the members’ time and ability.

Several changes resulted from members’ experiences and feedback. For example, the daily shift for a three-member processing team was changed because some members were unavailable for family and work reasons. Starting January 1993, MARCA hired a regular processor who was paid P40.00 daily. The MARCA members took turns in assisting the regular processor. Each member was paid P35.00 daily.

Developing an integrated enterprise

The viability of the cassava flour processing enterprise is expected to evolve only gradually because of competition from wheat flour and the lag involved in learning to use cassava flour. MARCA needed to engage in enterprises related to its flour processing operations to solve liquidity problems, improve income, and enhance capacity as a market strategy. Thus, in 1993, the following operations were integrated into MARCA’s business activities:

Trading. MARCA buys fresh roots from farmers and sells them to a starch plant situated about 80 km to the north. Trading is carried out from May to December when cassava drying is difficult because of the rainy season. Dried chips are bought during the dry season (January to April). Trading starts in the last week of November.

Operating a cooperative store to promote flour and feed. In November 1993, MARCA opened a village store (Mabagon is strategically located, serving mountain barangays) to sell flour, feed, and other cassava-based food products. Noncassava feeds for swine, such as the widely used base feed, were also sold to promote the MARCA feed mix, which had a higher protein content (14%-16% crude protein).

Market Development

Flour

The market target (25-30 bakeries, with a daily average total of eight bags, 10% cassava to wheat ratio) that would optimize plant use (4 t flour/month) was not reached within the first 6 months of operation. Only four bakeries were regular users and eight others were irregular, resulting in an average plant use rate of only 20%-30%.

The reasons for the slow penetration of the market were, first, learning how to handle cassava flour dough requires time, if both owner and baker are interested. If the price incentive was too low or the learning time too long, owners and bakers lost interest. Second, the number of bakers trained unexpectedly fell below target for the first 6 months. Third, the existing market used flour at a lower rate than expected (i.e., less than eight bags per day). Fourth, during the first year, the pilot project was still testing the stability of chip and flour quality, as well as test marketing, and an intensive marketing campaign was not being pursued at the time.

Given the results of this phase, the following marketing strategies were undertaken:

Visits and training. Consultation workshops, baker-to-baker visits, and training sessions were conducted to create the market for cassava flour. Twenty-five bakeries on Leyte Island were involved, from Maasin (about 45 km to the south) to Ormoc (about 80 km north). Visits between bakers gave them a chance to exchange ideas and experiences, and were more effective in transferring techniques and knowledge than was training. Because of the peculiarities in handling cassava-wheat composite flour, further market expansion will take time, as more training and exchanges are needed.

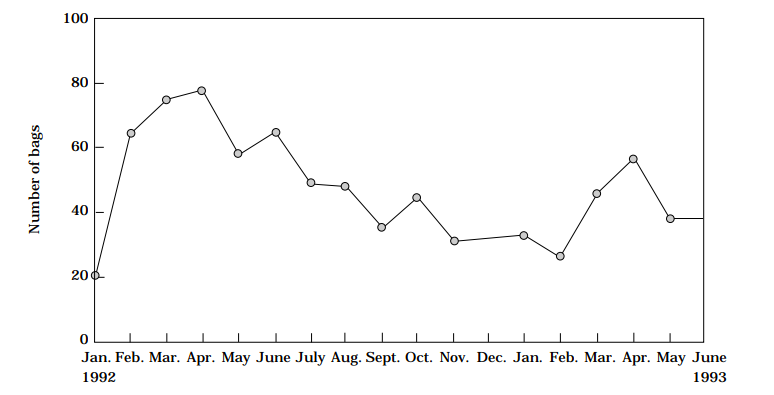

Market survey. The main constraints remained the lack of skills in using cassava flour for bread and the lack of price incentive. In 1993, cassava flour sales declined by more than 50%. From the informal market feedback, the nonsustainability of even the previous regular market may have been partly a result of the MARCA personnel’s inadequate marketing efforts (Figure 1). This meant that the trainees needed intensive exposure and training during the remaining months.

Promotional posters for cassava flour. Initially, 150 promotional posters were produced with funding from the PRCRTC’s extension program. These are now distributed in Leyte and Samar Islands and Surigao Provinces, and at the trade exhibits in the city of Cebu and at the Philippine Council for Agriculture and Resources Research and Development (PCARRD) at Los Baños (near Manila).

Testing other product ideas. Mixes with cassava-wheat composite flour were developed for the convenience food market. The 500-g packages, with recipes and an improved packaging design, was ready for promotion in November 1993.

Other markets explored. A distribution chain of native food products, with 150 outlets throughout the country and based in Manila, expressed interest in cassava flour. Samples of cassava flour, cassava meal (2 grades), and dehydrated cassava gratings were sent for testing. The cassava flour passed the quality test but the texture needed to be finer, to pass through a 60 mesh (down from the current 80). The dehydrated gratings were also acceptable and the firm is interested in placing an initial order. Grating equipment has been installed for processing and marketing trials for the first quarter of 1994. The cassava meal was unacceptable for ready mixes.

Processing other food products from cassava flour

To expand the market for cassava flour, MARCA members were trained in food processing. Three training sessions on various food products from cassava flour and fresh roots were conducted for MARCA members, one at Visayas State College of Agriculture (ViSCA) and two at the site. Because of a more promising market, MARCA decided to concentrate on cacharon and polvoron. The equipment is made and processing trials are expected to start during the first quarter of 1994.

Use of byproducts: cassava meal

Markets for cassava meal were explored. The flour is made into a native delicacy (ira-id) but the market is limited. About 2,000 kg of cassava meal were also sold to the ViSCA feed mill at P3.50 per kg. But this market is unstable.

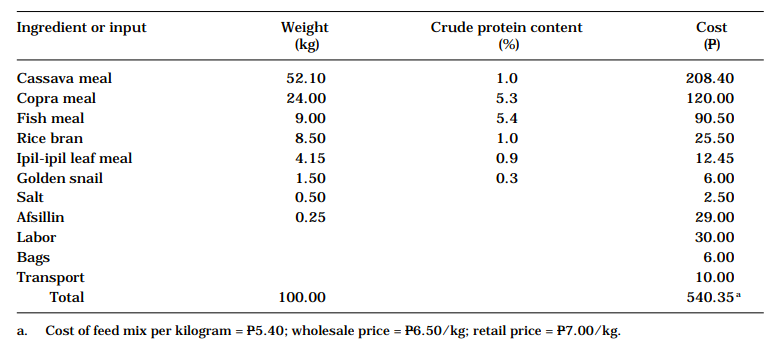

A more promising venture is to use cassava meal in swine feed mix. The ration was market tested in outlets in the nearby towns of Hindang and Hilongos. The formula contains about 15%-16% crude protein, as tested by the PRCRTC Laboratory. The price was competitive, being only about 72% of that of the popular base feed for swine.

The MARCA feed mix is made from pre-mix, and meals of cassava, fish, copra, and ipil-ipil leaves. Local women and children supply the leaves (Table 2). Profitability ranged from P0.50 to P0.75 per kg, depending on the sources of protein used. Other mix combinations, including kohol (a snail), will be tried out to determine the most efficient mix.

A plan is under way to promote the feed mix by integrating into MARCA’s operations the sale of complementary feeds, such as the swine base feed, which farmers commonly use.

Machine Evaluation and Improvement

Flour finisher

The first finisher brought to the site was a manually operated machine with a capacity of 20-40 kg/h when tested at the PRCRTC. But when used by the farmer-operator, it did not perform as expected. The flour clogged the screen, barely flowing out of the finisher. This was withdrawn and a temporary, manual one used until a new one was designed and made.

Motor-operated, the new finisher had a fan which forced the fine flour to pass through the screen. This machine had a higher capacity than the old one: at least 50 kg/h in a single pass. The cooperative’s members used it until another, improved, machine was made, based on farmer-operators’ evaluations.

The design now used has two main improvements: the feeder hopper was enlarged to accommodate a larger flour volume, and a metering device was mounted. These modifications improved the operation’s efficiency by removing the tedium of manually feeding and frequently stirring the ground chips in the hopper. They also reduced finishing time by about 50%.

Portable chipper

A portable chipper introduced to the cooperative was expensive for the members, having an estimated cost of P500. In contrast, the andolan—a local chipper made from a perforated GI sheet mounted on a piece of wood— costs about P15.00 per unit. The chipper was therefore not cost effective for individual households, because of the very small scale of home processing. The portable chipper also had to be mounted for the operator’s convenience.

However, the expected advantages of the portable chipper are an increased yield of chips and eliminated risk of abraded hands while processing. Cost-sharing among households may make the chipper more cost attractive.

Modified tapahan dryer

Dryers were used only during the rainy season, when sun drying was impossible and orders for flour had to be satisfied.

A dryer was constructed on site and tested. In the first two tests, it was too heavily loaded (463 and 200 kg of fresh chips), and the mixing turned the chips brown and hence unsuitable for flour production. In the third test, the chips were not mixed and their color was more acceptable for flour production. In the fourth test, the farmers evaluated the dryer, loading it with 190 kg of chips. The chips were not mixed, and dried in about 12 h. Their color was lighter than in the third test.

Improving Cassava Production Systems

Although the issue of environment friendly cassava production on sloping land was raised during informal discussions with farmers, it became a pressing concern with increasing commercialization. The issue of sustainability of cassava production and processing systems became integrated into the project. Two groups of cassava farmers from Hindang visited farming-system projects in Matalom, where model contour farms were shown. The farms had cropping systems similar to those of Mabagon and other cassava-producing communities. Farmers discussed the benefits of contour farming and the disadvantages of irresponsible farming. After two visits, seven model contour farms were set up in Hindang. These are still being followed up.

Project Management: Monitoring and Evaluation

Interdisciplinary team approach

Active interaction among team members was tried informally during field visits and discussions, and formally through monthly meetings. Although the independent contribution of each discipline was valuable, team members were constrained by having other responsibilities.

Resident research assistant

Living in the village enabled the resident research assistant to observe social behavior and norms. The assistant had to observe, facilitate, train, and catalyze the farmers, and monitor results in logbooks or diaries. The assistant left the village in July 1993 as farmers took over the flour production project.

The local advisory group

This interagency group consisted of local government representatives, the DTI officer, a technician from the Department of Agriculture, and representatives from the village and the farmers’ group, MARCA, and the PRCRTC. The local advisory group was to build up local management capability and to continue assisting MARCA after the PRCRTC left Mabagon in March 1994.

Monitoring and evaluation

These were done, first, by the team, based on observations from market surveys, field visits, and notes and feedback from the resident research assistant; and, second, through MARCA’s regular monthly meetings, and informal discussions with, and feedback from, MARCA. Farmer participation was always encouraged. Findings and observations were used to plan, modify, and improve the execution of activities.

Some Impact Indicators

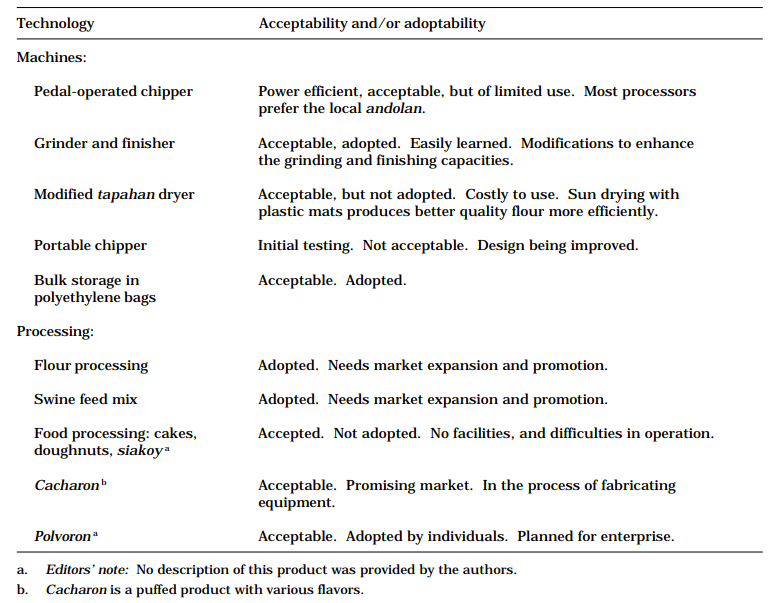

An important objective of the project was to assess the acceptability and adoptability of introduced technologies and their effects on processing and on farming households (Table 3).

Organizing and entrepreneurial skills

Markedly satisfactory performance was observed in terms of growth in cooperation, improved attitudes, processing skills, and enterprise management. It was also evident in group work, attendance at meetings, assemblies, workshops, participation in discussions, and carrying out of assigned responsibilities in operations and marketing.

Enterprise diversification

MARCA is learning to integrate related enterprises to make operations more viable and profitable. An “entrepreneurial” culture at the village level is gradually evolving.

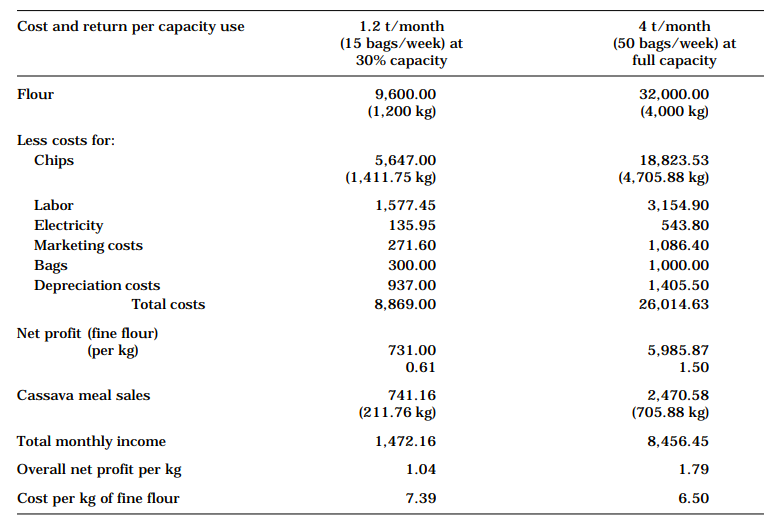

For the first 5 months of operation, at 30% capacity, the net profit per kg of fine flour was P0.61. With 90% capacity, this could improve to P1.50/kg. If cassava meal is included, net profit per kg is 1.04 at 30% capacity and P1.79 at full (Table 4). Financial statements (Jan.-Dec. 1992) show that, during the year’s operation, profitability decreased because plant use dropped to 20% (see Appendix). The enterprise’s profitability was improved with the use of cassava meal in feed mix. Profit per kg ranged from P0.50 to P1.10, depending on the ingredients used, which, in turn, were chosen so to obtain a feed mix price that was P2.50 lower than the popular, base feed brand.

Multiplier effect on the community

Market and income. From January to December 1992, MARCA bought from the farmers a total of 20 t of cassava chips, costing, in total, P73,921.00. This contribution to farmer income was substantial, compared with the chips market before MARCA, in which only about 5 t/year were sold, assuming an average of 3.5 bags/week. Farmers in Mabagon, Himacugo, Katipunan, and Baldoza are some of MARCA’s suppliers.

Improved chip quality. The quality (whiteness, aroma, and brittleness) of home-processed chips improved markedly, conforming to the desired moisture content (12%-14%). Proof of this was that flour quality stabilized.

Supplementary income via wage employment and other social benefits. Members derive satisfaction from earning even a minimal wage by working at the plant. They also feel a sense of achievement from learning new skills and being active in an enterprise—stimulated by motivation, pride, and hope that not all government projects fail. The buildup of entrepreneurial spirit, strengthening local institutions, and improvement in people’s organizational performance and attitudes are benefits which are difficult to measure. Yet they are essential for rural mobilization and growth. The processing plant became a source of prestige to the community, and gave farmers confidence that they could achieve even more.

Conclusions and Recommendations

The approach

This exploited the skills of, not only different kinds of researchers, but also of the beneficiaries themselves. The participatory process eventually gave the farmer-processors a sense of achievement: that through interactive, informal discussion with researchers they could make effective decisions. Such “ownership” of achievement is key to the buildup of capacities, which can only be achieved through gradual experiential learning.

Local people’s involvement in project management also eased the task of team members who were constrained by time and resources. Local agencies shared responsibilities. Once the project ends, their familiarity with it will enable the locals to continue managing the established enterprise.

Defining the focus and making the project small and simple intensified technology learning and enabled the processors to stabilize product quality.

Participatory observation helped discover social processes and interrelationships, facilitating the modification or redesign of introduced technologies. Behavior and attitudes are central concerns in the process of technology transfer, preconditioning technology adoption. The project also facilitated on-the-job learning of technical and entrepreneurial skills. Placing a qualified resident research assistant in the field significantly facilitated technology transfer.

Technology viability

The commercial viability of cassava flour processing depends largely on intensifying the farmers’ understanding of cassava flour use and market expansion. Currently, commercial cassava flour production is not viable without integrating the commercialization of byproducts, expanding end uses of flour as, for example, a raw material in other products and food processing, or trading related complementary products. To encourage farmers to set up a successful enterprise therefore requires a carefully integrated plan, in which each step, made small, simple, and focused, is gradually introduced. The step-by-step process would help farmers understand that every product or additional activity needs a minimal standard of quality, stable supplies, good service, and competitiveness.

A pilot and commercialization project should therefore have the institutional or external support for investment in market research and promotion because farmer groups usually do not have the needed funds to start up marketing activities.

Institutional flexibility

The research team members must be sensitive if they are to successfully collaborate in arranging development activities in such a way that the project has technical, marketing, economic, and operational viability. From the beginning, team members must understand the need for such sensitivity even in the planning process. The project’s success depends on the ability of the team and farmers to respond to changes, and modify plans and strategies to achieve objectives. Planning then becomes an iterative process. But being responsive to uncertainties can be demanding on the team, which demands, if not addressed, may cause delays or even failures.

This implies that some degree of institutional flexibility is needed in teaming up and distributing workloads to ensure that researchers have adequate time to undertake the responsibilities involved in a “commercialization” project. These responsibilities are based on the implications of the integrated process approach: a commitment to (1) using participatory research methods, and (2) ensuring interactive learning between farmers and researchers.

The integrated approach also assumes the availability of a minimum, adequate, institutional support to permit the exercise of the two basic responsibilities and provide the support services needed to make the project work. The policies of the participant institutions should thus be geared toward making the integrated approach work.