Wheat flour is often used as the starting material for separating starch and gluten because it has a higher starch content and fewer by-products than whole grains. Major components of wheat flour include proteins, starch, nonstarch polysaccharide, lipids, and fiber.

In cereal technology, the hardness of wheat kernels is an important factor in milling because it affects yield, particle diameter, density, and starch damage. Diversification and classification of wheat grain for different technological purposes are necessary to achieve optimal flour quality and end-use properties.

Wheat grains contain two types of starch granules: larger A-type granules and smaller B-type granules. Separating flour into starch and gluten fractions can be difficult due to the adverse particle size distribution of starch granules, especially the presence of small granules. Preliminary studies of flour are necessary to determine its usability for starch production.

Water is used to extract starch from flour because it causes minimal damage to the starch and is safe and cost-effective.

Gluten and starch are separated based on their insolubility, density, and particle size, and industrial processes such as centrifugation and sieving are used for this purpose.

B-grade starch is obtained after extracting the gluten and A-grade starch, and it can be further refined through particle extraction.

Different types of starch have different processing requirements based on their particle size, which can be affected by factors such as the age of stored flour, chlorination, or heat treatments.

The binding force between starch tailings and prime starch is hydrophobicity, which increases with age, chlorination, and heat treatments.

Several processes, including the conventional Martin and Batter processes, and the modern Alfa-Laval/Raisio, hydrocyclone, and HD processes, are used for the wet milling of wheat flour.

In the Martin process, wheat flour with 15% moisture content is mixed with water and matured to form a gluten matrix. The dough is then washed to separate starch milk and wet gluten. Starch milk is refined using decanters and then transferred to a vacuum trap and pneumatic dryer to obtain pure starch with 12% moisture content. B-type starch is obtained from the material discharged from the decanters, which can be used for the production of spirit or as a component of animal feed. The Martin process yields around 60-85% A-starch and 5-10% B-starch.

Decanters are used to separate compounds with high concentration and dry matter content. Different types of decanters can produce three concentrated fractions: the lightest, containing water-soluble compounds such as nonstarch polysaccharides, proteins, and salts; the medium fraction, containing concentrated gluten, parts of the seed coat, and B-type starch; and the most dense and most dry fraction, consisting mostly of A-starch. These fractions are concentrates and require further processing, which includes cleaning of starch and gluten.

The Martin process fails to wash out approximately 5% of starch from the dough. The B-starch stream can be further split to produce a lower grade C-starch, depending on the product requirements.

European research projects have achieved good results in terms of yield and purity of starch by using “super soft” wheat flour and separating protein fraction and starch with a stream of air. The research is also focused on breeding wheat varieties with higher A-starch content without reducing the total starch content.

In the Martin process, the starting material is wheat flour with a moisture content of 15%. The dough is matured and washed to separate starch milk and wet gluten, which are refined to obtain pure starch and B-type starch. The Martin process yields around 60-85% A-starch and 5-10% B-starch, depending on the product requirements. Decanters are used to separate compounds with high concentration and dry matter content, and further processing is required to clean the starch and gluten.

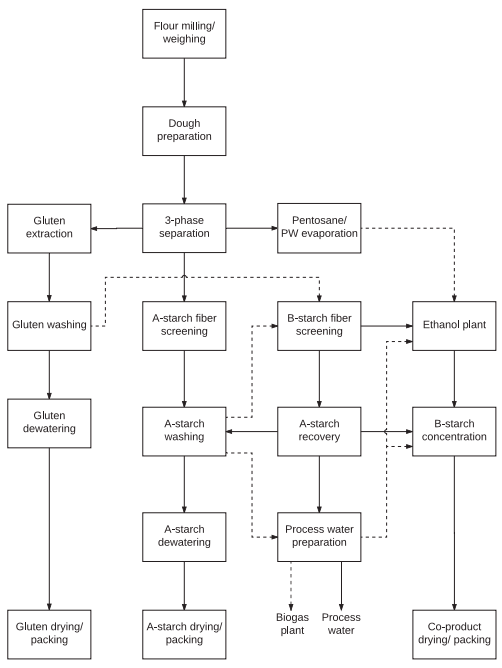

In modern technologies (Figure 1), the raw material-wheat flour is mixed with water and then subjected to conditioning and homogenization using a pressure homogenizer. Such prepared dough is separated on a three-stage horizontal centrifuge (three-stage separator) into three phases: starch milk into A-starch, starch milk (into B-starch), gluten, and pentosans.

Starch milk is processed into A-starch by sieving, refining, dehydrating, and drying. The by-product is the light phase which contains pentosans and solutes. The stream is sieved, dehydrated, and dried to obtain B-starch. The concentrate is returned and the rest is sewage. The gluten phase is screened off, washed, and dried to become Vital Gluten. The waste after refining and washing gluten is transferred onto a recuperative separator and then a thickening one. The obtained concentrate is combined with a fraction of B-starch milk before entering the dehydrating decanter. The modern technology used is the three-phase decanter which allows for more efficient washing of the starch milk, making further purification more efficient.

Starch can be obtained by using laboratory-milled flour with either a 0.1% aqueous solution of sodium chloride (traditional method) or a 0.5% aqueous solution of sodium hydroxide (NaOH). Starch isolated by NaOH has a lower content of noncarbohydrate components. Using NaCl allows for obtaining wet gluten which can be used for different purposes. The method using NaCl also allows for obtaining starch pastes with a higher maximum viscosity in comparison with the method using NaOH solution.

The NaCl solution method does not inactivate the amylolytic enzymes contained in flours which are responsible for a partial hydrolysis of starch during its isolation, altering its original properties. The use of NaOH solution during the process of starch isolation prevents the occurrence of adverse changes, as evidenced by a lower reactivity of obtained starch. Both methods of starch isolation allow us to obtain high-purity products. pH treatments of wheat starch solutions affect the amount of recoverable crude starch, the content of lipids, proteins, and pentosans within the various fractions, gelatinization temperatures, and enzymatic hydrolysis activity. The amount of crude starch recovered from starch milk by centrifugation was relatively constant up to pH 8.5, less at pH 10, and none sedimented at pH 11.5.