Commercial starch hydrolysates are classified on the basis of dextrose equivalent (DE). Maltodextrins are by definition starch hydrolysates (nonsweet saccharide polymers) that consist of α-D-glucose units linked primarily by (1->4) glycosidic linkages with a DE of less than 20, and a general formula of [(C6H10O5)nH2O].

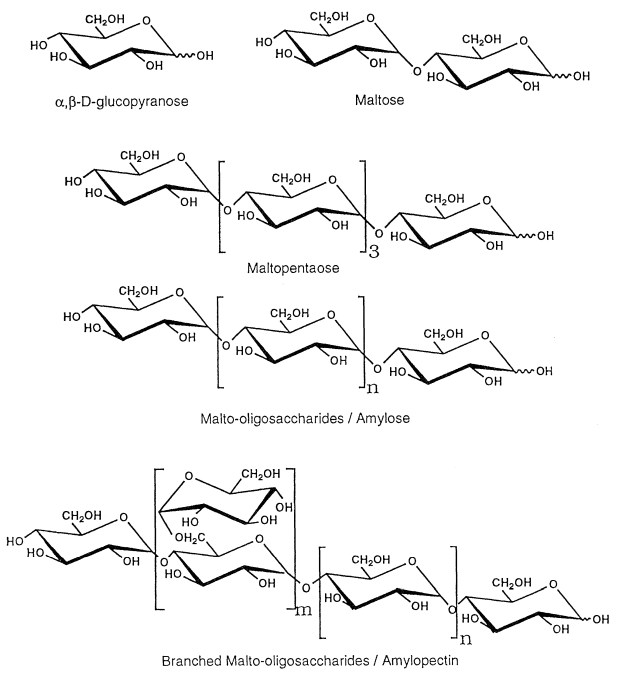

DE is defined as the percentage of reducing sugar in a syrup calculated as dextrose on a dry weight basis. The definition of maltodextrins can thus be taken further as those materials have a dextrose equivalent of between 3 and 20. They, therefore, essentially bridge, in terms of molecular size, the gap between starch and sugar (Morris, 1984). The DE reflects reducing power, and therefore indicates stability and functionality. Starch hydrolysates with a DE greater than 20 are designated as various kinds of syrups depending on their source (e.g. corn syrups). Figure 3.1 shows the structural components of a maltodextrin mixture. Starch hydrolysates are increasing in commercial importance due to their unusual properties. In general, maltodextrins are fully soluble carbohydrates of low bulk density, they can be metabolized in a similar way to starch and in some applications are therefore suitable for diabetics (Anon, undated (a)). Interestingly maltodextrins have very little or no sweetness and a bland, not starchy flavor that does not mask other flavors (Morris, 1984; Anon, undated (a)). Due to these properties, maltodextrins are finding a considerable number of applications within the food industry, particularly in convenience and processed foods.

Maltodextrin production

The production of maltodextrins is, by definition, achieved by the hydrolysis of starch down to glucose polymers with an average chain length of 5-10 glucose units/molecule. Theoretically, they can be produced by controlled hydrolysis by either enzymic (α-amylase) or acidic (usually hydrochloric acid) means (Anon, 1989a), however in practice acid hydrolysis produces too much free glucose and maltodextrins thus produced have a strong tendency to retrograde, resulting in the formation of hazy solutions.

Linear starch fragments in low DE acid hydrolysates large enough to reassociate form insoluble aggregates causing hazy solutions which are undesirable for some applications. Therefore on a commercial level maltodextrins are invariably prepared from starch by controlled enzymic hydrolysis (Morehouse et al., 1972a, b). A starch slurry is initially liquefied by heating to 70-90°C at neutral pH in the presence of a bacterial α-amylase to a DE of 2-15. The liquid starch hydrolysate is then autoclaved at 110-115°C to gelatinize completely any remaining insoluble starch and, on cooling, subjected to further enzymic treatment to reach the desired DE. Some hydrolysis schemes, however, employ both acid- and enzyme catalyzed hydrolysis. Initial acid-catalyzed hydrolysis of a starch slurry to a DE of 5-15 followed by neutralization and further hydrolysis with a bacterial amylase-amylase such as that obtained from Bacillus subtilis or Bacillus mesentericus is a recommended procedure to produce maltodextrins that are haze free and exhibit no retrogradation upon storage (Armbruster and Harjes, 1969, 1971). Such systems overcome the problem of hazy solutions and result in maltodextrins with low hygroscopicity and high water solubility. The source and variety of the starch is unimportant for these processes.

Following hydrolysis, the pH of the crude maltodextrin solution is adjusted to about 4.5 and the solution is filtered to remove small amounts of fiber, lipid and protein. Filtration can prove difficult due to the high viscosities of maltodextrin solutions and this processing stage can lead to substantial losses in yield. The clarified solution is then further refined by one or more of the procedures used for corn syrups, such as carbon refining. The refined solution is then concentrated in vacuum evaporators to give finished syrups containing about 75% solids, or more regularly, is spray dried to a white powder containing some 3-5% moisture.

| DE | Glucose (%) | Maltose (%) | Maltotriose (%) | Higher saccharides (%) |

| 15 | 0.6 | 4.0 | 7.0 | 88.4 |

| 20 | 0.8 | 5.5 | 11.0 | 82.7 |

Two types of maltodextrin are in commercial use: those ranging from about 10-14 DE and those ranging from about 15-19 DE. The compositions of these products depend not only on DE, but also on the method of hydrolysis employed in their manufacture. The saccharide component profiles of maltodextrins obtained by acid-catalysed hydrolysis are somewhat different from those obtained by enzyme- or acid/enzyme-catalysed hydrolysis, even though they can possess the same DE. Acid hydrolysates tend to contain greater proportions of high molecular weight dextrins, which retrograde easily.

Gelling maltodextrins are obtained by hydrolysis of potato starch with bacterial α-amylase. At concentrations above 10% (w/w) and temperatures below 30°C their aqueous solutions solidify to give thermally reversible gels. Melting takes place as a function of concentration between 45°C and 85°C. Maltodextrin gels are two-phase systems resulting from mutual interactions between amylose molecules and sufficiently long amylopectin chains resulting in the formation of a mixed gel structure (Schierbaum et at., 1986; Vorweg et at., 1988).

Properties of maltodextrins

The varying properties of maltodextrins are indicated by the DE and the degree of polymerisation (DP), which change with the degree of hydrolysis and enzymic treatment (Morris, 1984; Ziesenitz and Siebert, 1987). The solubility of maltodextrins varies with DE and with the method of hydrolysis. Enzyme-hydrolysed products usually contain lower concentrations of the high molecular weight saccharides and are thus more water soluble than acid-hydrolysed products of equivalent DE. Maltodextrins are relatively non-hygroscopic compared with corn syrups, and those having the lowest DE exhibit the least tendency to absorb atmospheric water (Morris, 1984).

The high viscosity of maltodextrins, an important property in many applications, is due to high levels of high molecular weight saccharides (Anon, undated (b)). Since maltodextrins exhibit virtually no sweetness, their main contribution is a ‘bodying effect’ resulting from their relatively high viscosity. The varying DE/bulk density give maltodextrins their varying characteristics and functionality. For example, the high DE maltodextrins have solubility, bulking and bodying characteristics more similar to the corn syrup sweeteners.

The low DE maltodextrins have the binding properties of starch and can function more effectively as fat binders than high DE maltodextrins. Low DE maltodextrins are effective in preventing formation of coarse crystals (Anon, undated (a)). The variety of sugar polymers in maltodextrins prevents the formation of large, gritty crystals as sugar mixtures will not crystallise as readily as pure compounds. The fine particle size of maltodextrins contributes to a smooth, creamy mouthfeel in many food products (Anon, undated (a)).

Applications of maltodextrins in food and related areas

Maltodextrin uses are widespread throughout the food industry and they perform multifaceted functions in food systems; a wide range of products are available in powdered and syrup forms. The functionality of each type varies with extent of starch degradation. If a glucose syrup is spray dried to produce a soluble white powder it gives a product which is convenient and easy to handle. The powder’s characteristics are, to a certain extent, dependent upon its DE, but in all cases, the maltodextrin will be soluble, have a low bulk density and low sweetness.

Batches with a higher DE are more sweet and more hygroscopic than their low DE counterparts. The properties and cost of maltodextrins make them ideally suited to application within the food industry, where their uses include:

- as bulking/filling/carrier agents,

- as sweetness reducers,

- other uses, e.g. oxygen barrier and film forming.

Bulking/filling/carrying

Due to their low sweetness and high solubility maltodextrins are ideally suited for blending into powdered formulations. The purposes for which they have been used include:

- to save costs by replacing (or partially replacing) a higher cost material. Examples are lactose/milk powder in certain applications such as tablet manufacture, albumin in marshmallows etc.

- as a non-flavoured dilutant for concentrated ingredients such as flavourings and flavour enhancers

- to reduce loss of volume on storage or transit

- to absorb oil/fats

- to aid dispersion

- to give a bland taste

- to increase nutritive content

- to increase solubility.

Sweetness reducers

Maltodextrin addition is by far the most effective method for reducing sweetness without altering properties currently available to the food/ beverage industry. Many products can be made more palatable by lowering their level of sweetness without reducing their total solids content. This is of use in foods and drinks containing high sugar concentrations (for example confectionery, preserves, fillings and fondants). Additionally in recent years this utilisation has spread to isotonic energy supplement drinks specifically designed for those in a sporting or active environment. The success of these energy replacement drinks may, however, have a great deal more to do with fashion and successful advertising policy than science.

Specific examples of maltodextrin food applications

Baked goods

Maltodextrins can be used in bakery goods as a gram-for-gram replacement for either sucrose or fat. Examples include Paselli SA2 used in cakes, muffins and cookies as a fat replacer and Amalean I used in reduced fat products such as cakes and cheesecakes.

Frozen desserts

Replacement of sugar often requires a combination of two or more bulking agents in order to directly duplicate the functional properties of that sugar (e.g. freeze point depression, ice crystal control and structure/bulk contribution). Frozen desserts use maltodextrin because its water holding capacity combined with relatively low molecular weight give it freezing point depressant qualities.

Low calorie dry mix

A wide variety of low calorie mixes have been produced with the aid of artificial sweeteners, including hot and cold beverage mixes. Once again the maltodextrin is used to replace the bulking characteristics of the original sweetener since many sugar substitutes have intense sweetness, and therefore are only required in small quantities.

Margarine spreads

Maltodextrins are used in reduced calorie margarine spreads, with a typical reduced calorie table spread containing just 4.5 kcal g-1 as opposed to 7 kcal g-1 for a conventional margarine whilst retaining similar properties (Anon, 1990b).

Reduced fat meat products

Paselli SA2 has been used to decrease the fat levels of meat products. Maltodextrins are also finding use in reduced fat soups and gravy mixes (Anon, 1989b, undated(c)), their purpose again being to reduce fat by direct replacement.

Salad dressing

Maltodextrins have successfully been used in the production of reduced fat salad dressings (Klis, 1984).