The viscosity of glucose syrup in relation to its solids content and temperature is an important factor when the product has to be pumped and stored, as heating may need to be provided for storage tanks and heavy duty pumps required to transfer the material. The viscosity of glucose syrup is directly related to its moisture content and its molecular weight (and thus inversely related to DE). It is also related to the carbohydrate composition of the syrup and this effect is particularly significant when selecting a glucose syrup for confectionery manufacture. A 42 DE high maltose syrup for example has a lower viscosity than a 42 DE acid converted syrup at the same solids content. Temperature is very important in relation to viscosity and viscosity decreases as temperature increases. Hydrogenation, predictably, has no apparent effect on the viscosity of glucose syrup.

Table 1 shows typical values for the viscosity of a range of glucose syrups at 75% solids content over a range of temperature (adapted from Corn Refiners Association, 1975).

| Viscosity (cP) | ||||

| Temperature (°C) | 30 DE | 40 DE | 60 DE | 80 DE |

| 15.5 | 70000 | 20200 | 5500 | 2000 |

| 26.7 | 19000 | 6200 | 1700 | 700 |

| 37.8 | 5500 | 2200 | 650 | 300 |

| 48.9 | 2000 | 900 | 300 | 150 |

| 60.0 | 850 | 420 | 150 | 75 |

| 71.1 | 450 | 210 | 80 | 45 |

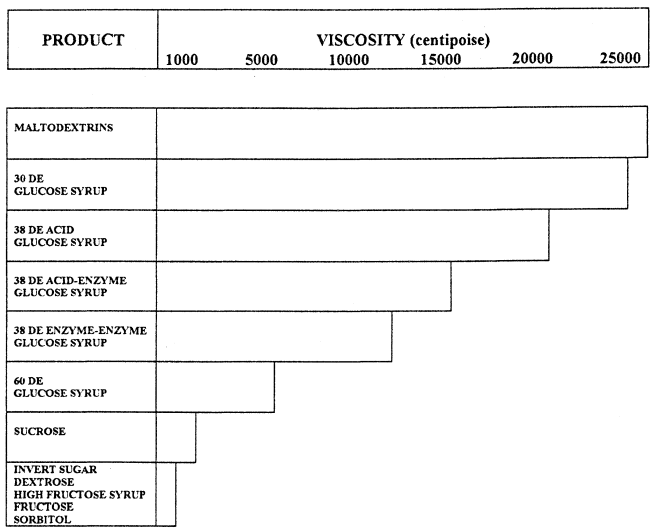

Whilst the above data apply generally to glucose syrups different manufacturing techniques acid/acid-enzyme/enzyme-enzyme result in differences in viscosity at the same DE, all else being equal. For example, acid-enzyme and enzyme-enzyme 38 DE glucose syrups have a lower viscosity than acid 38 DE syrups. This is illustrated in this figure:

For bulk handling of glucose syrups, the temperature of the product is critical both from viscosity and browning viewpoints and also with higher DE syrups to prevent dextrose crystallization. Table 2 shows typical storage temperatures for a range of glucose syrups.

| Syrup | Solids content (% w/w | Minimum storage temperature (°C) |

| 38 DE Acid glucose syrup | 75 80 85 | 40 50 60 |

| 38 DE Acid/enzyme glucose syrup | 75 80 85 | 35 45 55 |

| 42 DE Acid glucose syrup | 75 80 85 | 35 45 55 |

| 60 DE Acid/enzyme glucose syrup | 75 80 85 | 20 30 45 |

Bodying effect is related to viscosity. This is of particular importance in soft drinks where it is often described as mouthfeel and is basically a description of the roundness or fullness of the syrup in the mouth. The higher the viscosity the greater the bodying effect.