The cassava flour project in Colombia began in 1984 with financing from the International Development Research Centre (IDRC). It seeks to increase the income of small farmers in cassava-growing areas by creating an agroindustry focused on the production of cassava flour for human and industrial consumption.

The following discussion of the project “Production and marketing of cassava flour in Colombia” outlines the underlying methodological framework, and describes the project activities executed during the research, pilot project, and expansion phase. Emphasis is given to the pilot project.

Methodological Framework

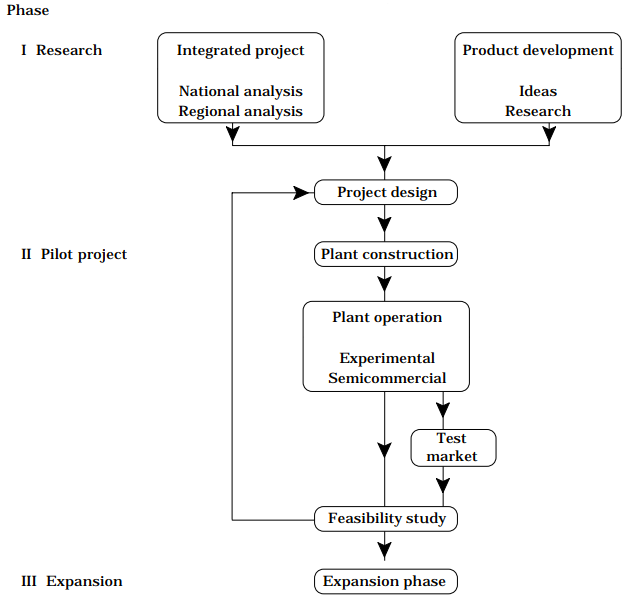

The project uses integrated project and product development methodologies. During the research stage, activities can be seen as belonging to one or the other methodology (Figure 1), but as blending in the pilot project.

Product development concentrates on three main areas: first, the generation, evaluation, and selection of ideas for new products, in this case cassava based; second, the development of a product prototype and process design, accompanied by industrial and/or consumer research; and, third, product presentation, that is, quality specifications, product name, and packaging.

The term “integrated cassava project” describes a rural development strategy, executed in three phases by rural inhabitants, to promote the agroindustrial transformation of cassava through the integration of production, processing, and marketing functions and supported by governmental and nongovernmental organizations.

The research phase is in two parts: national analysis, in which the national economy, the commercial outlook for cassava, and the potential of ideas for new cassava-based products are studied to select new products and a region. In the second part—regional analysis—the selected region is studied in greater detail, especially regarding cassava production, farmer organizations, and nearby markets, to select the best scenario for a pilot project.

During the second phase—pilot project—a pilot plant is established and operated semicommercially under real market conditions to determine the feasibility of the agroindustry.

In the final phase—expansion— the processing units are replicated and the market for the product is expanded to consolidate the new agroindustry.

Evolution of the Cassava Flour Project

Research phase

The objective of this first phase was to determine the technical and economic conditions required for developing the cassava flour agroindustry in Colombia. The main use anticipated for cassava flour was in the preparation of a wheat and cassava composite flour for bread making.

The region selected, the North Coast—also known as the Atlantic Coast—is the main cassava-producing area in Colombia, with the root grown mostly by small-scale farmers. Accordingly, the economy of cassava production in the North Coast was studied, along with the wheat-milling and bread-making sectors. The equipment for small-scale rural processing of cassava was adapted and developed. In addition, the influence of cassava varieties on the quality of cassava roots and derived products was examined. Surveys among consumers and bread makers were conducted to evaluate the acceptability of breads made from composite flours of wheat and cassava.

The research concluded that the development of a cassava flour agroindustry was viable because cassava flour could be sold at lower prices than wheat flour, and consumers found the composite bread acceptable. However, bakers saw a high risk in lowering the quality of their products by using cassava flour.

The decision was made to continue with the pilot project, on the understanding that alternative markets for cassava flour were identified.

Pilot project phase

In this phase a pilot cassava flour plant was set up and operated under real market conditions to assess the feasibility of establishing the new agroindustry. The following activities were carried out:

Adjusting and evaluating production. A set of criteria (such as stability of farmer organizations or performance of cassava crops) was determined and used to select the site for the pilot plant at Chinú, Córdoba. The Cooperativa de Productores de los Algarrobos (COOPROALGA) was chosen as the executing farmer organization. The pilot plant was designed, and a local civil engineering firm built it within 3 months. Most of the equipment and machinery was manufactured in a Cali workshop but the metallic coal burner was available commercially. A well was dug to supply the plant with water.

Workers and administrative personnel were selected and trained. A daily and weekly timetable of activities was drawn up and an almost year-round supply of fresh cassava roots coordinated. In total, 42 t of dried chips were produced and transported by road to be milled in a commercial wheat mill in Medellín.

An information system for production was developed and implemented, and control parameters established. Specifications for the quality of raw material and sanitary controls were drawn up. The microbiological quality of the cassava flour was monitored, and variable costs of production closely supervised.

Support research was conducted, with the collaboration of the Universidad del Valle (UNIVALLE) and the Natural Resources Institute (NRI), UK. Areas investigated included the improvement of processing equipment, control of microbiological quality of cassava flour, development of a small-scale milling system for cassava chips, research on storage of cassava products, and development of moisture-measuring equipment for cassava products.

Testing and demonstrating an improved cassava production technology for the North Coast. Since 1989, 120 farmer-managed pre-production plots for demonstration were established on the North Coast with cassava-maize and cassava-maize-yam combinations; farmers were supervised by an agronomist.

The recommended technologies, which improved maize and cassava yields, combined adjustments in the use of preemergent herbicides, fertilization of maize and yam, more intensive use of human labor, and use of improved maize varieties.

Identifying markets for cassava flour and product promotion. As described above, the focus on bread making was modified after the research phase. Market opportunities were sought in other food industry categories where cassava flour would have an equal or better functional advantage or where it could be substituted, partially or completely, for other flours or starches.

A market study was conducted nationally among food companies of different sizes. The study first focused on products marketed and raw materials; then, flour samples were distributed for substitution trials; and, finally, feedback was obtained on the trials and buying intention was gauged. The study showed that potential markets for cassava flour included processed meats, cookies, ice-cream cones, pasta, pastry, soup and sauce mixes. Cassava flour exhibits functional advantages in most of these products. More than 80% of the volume would be destined to replace wheat flour. Assuming that cassava flour could be sold for 10% less than wheat flour and that there would be adequate promotion, the estimated mid-term market demand would be 20,000 t/year.

The promotional effort concentrated on Medellín, which had milling facilities and the largest single market detected in the study. Sixteen firms were visited and given free samples of flour. The subsequent trials were closely monitored. Inferences from this experience were that the microbiological quality was not acceptable to most companies, that the food industry was conservative, and that sales efforts would benefit from better technical information on cassava flour.

The flour developed was yellowish white and contained about 80% starch. Its granule size was smaller than that of wheat flour. It was called “Yukaribe,” and packaged in polypropylene sacks, complete with a graphic design. The flour was priced at 15% below wheat flour.

Feasibility of the agroindustry: pilot project phase. A computerized financial model of the pilot plant was designed and updated periodically to monitor production costs, plant efficiency, and profitability. At the end of the pilot project phase, the feasibility of the cassava flour agroindustry was seen as follows:

- Technical feasibility. The artificial drying process was inefficient; and the microbiological quality of cassava flour was substandard.

- Commercial feasibility. Additional technical information was required. The physicochemical and microbiological qualities needed improvement.

- Cooperative-management feasibility. Sales and marketing personnel were needed to handle product marketing.

- Economic feasibility. The financial rate of return (FRR), a profitability parameter, was calculated at 22%, which was considered low.

Expansion phase

The project could not proceed with a formal expansion phase because of the constraints described above, but some action could be taken in preparation for a future expansion. A hybrid pilot/expansion phase was developed to convert the pilot plant into a commercial operation with improved profitability.

Artificial drying costs were greatly reduced by doubling heat generation and switching from coke to mineral coal. This resulted in a shorter drying period and improved flour microbiological quality.

The plant received a small cassava-chip mill, developed jointly by CIAT and UNIVALLE. The mill consisted of a premilling component that reduced chip size and two cylindrical screens that also functioned as mills. The output was a first-grade flour (70%-85% extraction) and bran. In-plant milling reduced variable costs and contributed toward satisfying local demand for the product.

Members of COOPROALGA, the farming cooperative managing the pilot plant, were trained in the administration of small enterprises.

Developing and executing a plan for expanding the cassava flour agroindustry in Colombia. Cassava flour was promoted among the North Coast food industries, especially meat-processing, cookies, and spices, with the eventual penetration of the meat-processing sector.

However, to increase sales further, the marketing strategy was changed and cassava flour was promoted in nonfood industries—especially adhesives and plywood—where microbiological quality was less important and higher market prices could be obtained. Adhesive companies in major Colombian cities were provided with samples of cassava flour and, simultaneously, the Fundación para la Investigación y el Desarrollo de Tecnologías Apropiadas al Agro (FUNDIAGRO) provided support in the development of cassava flour-based adhesives. The adhesive markets in Cali and Barranquilla were penetrated, although industrial requirements demanded increased flour purity by reducing the extraction rate during milling.

The design of the prototype building for the processing plant was revised to reduce costs and increase performance in accordance with the pilot project experience. Designing involved a team of architecture students from UNIVALLE, supervised by a member of the university staff.

Training materials, including videos and manuals on production and management, were developed.

Feasibility of the agroindustry: expansion phase. By the end of 1993, the feasibility status of the cassava flour agroindustry was seen as follows:

- Technical feasibility. Food industry: yeasts levels were too high. Adhesives industry: no limitations.

- Commercial feasibility. Food industry: additional technical information on cassava flour was required by firms; physicochemical and microbiological quality required improvement; cassava flour price is competitive against wheat flour only in the North Coast. Adhesives industry: additional technical information was required by firms.

- Cooperative-management feasibility. Food and adhesive industries: sales and marketing personnel were needed to handle product marketing.

- Economic feasibility. Food industry: FRR was 26%. Adhesives industry: FRR was above 30%.

Conclusions

The major outputs of the cassava flour project were:

(1) The development of an efficient small-scale system for cassava flour production.

(2) Although members of the executing cooperative had been trained to manage the plant, a major priority was to improve the quality of the raw material used in the plant, including industrial varieties.

(3) Project feasibility is uncertain, because of high costs, deficient supplies, poor quality of the region’s cassava roots, and insufficient entrepreneurial capacity of the executing cooperative.

(4) To plan successful rural agroindustrial projects, the following points must be considered:

- (a) the importance of the integrated, or entrepreneurial, approach, encompassing interventions in production to guarantee a sufficient supply of low-priced, quality raw material;

- (b) the need to assign enough funds and time for product development and marketing; and

- (c) the need to identify project executors with entrepreneurial abilities.