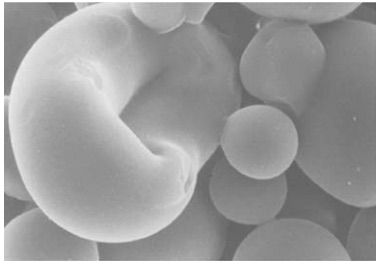

Microscopy, light microscopy and scanning electron microscopy, has played an important role in increasing the understanding of the granular structure of modified starches. It has been used to detect the substituted regions’ microstructural changes in starch granules (Kim et al., 1992; Singh et al., 2004). Changes in appearance of starch granules after hydroxypropylation have been reported for potato (Kim et al., 1992) and cassava starches (Jyothi et al., 2007). Most of the structural changes upon hydroxypropylation take place at the relatively less organized central core region of the starch granule, i.e., where the hydroxypropyl groups are most densely deposited. Pushing-apart effect and donut-shapeelike granule of propylene-treated potato starch have also been reported by Huber and BeMiller (2001) and Singh et al. (2004) (Figure 1). The structural changes in hydroxypropylated starch granules become more evident with increasing MS (Kaur et al., 2004; Kim et al., 1992). However, there was no change in surface or shape characteristics of the hydroxypropylated canna starch granules (Chuenkamol et al., 2007) and pigeon pea starches (Lawal, 2011). These altered regions were apparently larger in large granules compared with small granules in all the potato starches examined, which may be attributed to differences in the native granule architecture and fragility.

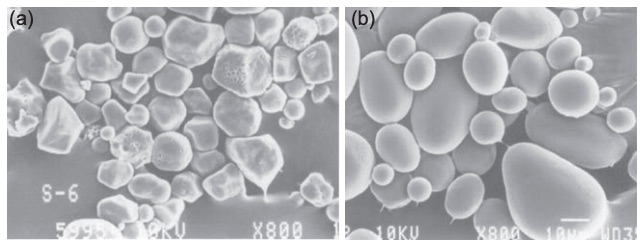

Acetylation treatment has also been found to alter granule morphology, although to a lesser extent than hydroxypropylation in some starches (Singh et al., 2016). Some researchers have found that potato, maize, and rice starch granule surface becomes rough and the granules tend to form aggregates upon acetylation (Figure 2) (Gonzalez and Perez, 2002; Sha et al., 2012; Singh et al., 2004). Some granule fusion and deformation and the rough appearance of the granule surface in the acetylated potato, maize, and rice starches might also be the result of surface gelatinization upon addition of NaOH for maintaining alkaline conditions during acetic anhydride addition. As the degree of acetylation increased, the intermolecular hydrogen bonds were damaged and starch granule structure was more disrupted (Sha et al., 2012; Singh et al., 2004).

The starch granule size of cross-linked starches is very responsive to the changes in the DS by substituted phosphate groups: the higher the DS, the larger the granule size. The average increase in granule size has been observed to be higher for rice and MS than for potato starch for a given DS. The increase may be because of the substitution by phosphate groups inside the modified granules, building certain repulsive forces that increase the sizes of inter- and intramolecular spaces and allowing more water molecules to be absorbed. Phosphorylated potato starches can be prepared using a mixture of mono- or disodium phosphate (Singh et al., 2016). Studies on waxy maize starches (WMSs) using different reagents (POCl3 and propylene oxide) reported the variations in the relative reaction patterns (Huber and BeMiller, 2001). The microstructural changes of cross-linked starches predominate on the granule surfaces as a result of using highly reactive POCl3 owing to the higher reactivity of POCl3, and contrarily, using less reactive propylene oxide generally diffuses into the granule matrix before reaction (Huber and BeMiller, 2001; Kaur et al., 2004). Shiftan et al. (2000) reported that epichlorohydrin (EPI) cross-linking is not homogeneous and is concentrated in the noncrystalline domain of starch granules.