Methods of starch recovery vary greatly depending on the country, age of the plant, and starting material. They all however follow the simple principle of extracting the starch in the highest possible yield. Methods often use repeated wet grinding techniques coupled with cyclone separators or conventional centrifuges and are based on the water insolubility of starch and variations in density and size of the different granule components to obtain a pure starch product. Almost all commercial starch manufacture is now carried out using continuous processes.

In the recovery of starch from whatever source it is important not to neglect the recovery of the other grain or tuber constituents, e.g. bran(fiber), protein, and fat. It is usual practice to recover as much of these as possible for sale into a range of industries, e.g. animal feed and fermentation, so that nothing (or very little) goes to waste. This ensures low effluent treatment costs and increased revenue for the starch producer.

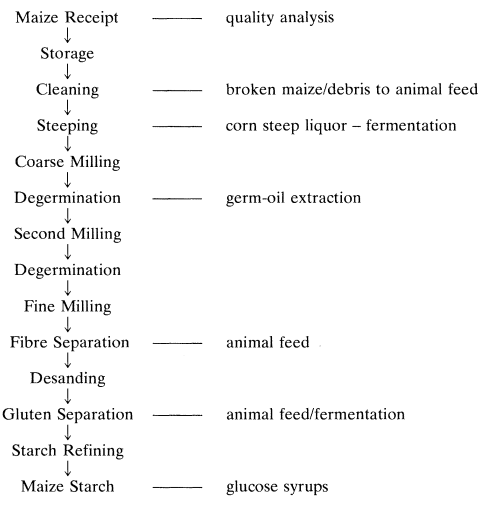

Maize starch

Maize starch is recovered from maize nibs by a wet milling process. In Europe, most plants use homegrown dent corn varieties. The schematic outline of the process is shown in Figure 1.4.

Dry milling processes have also been developed but the high oil content of maize (in the germ) lends itself more readily to the wet process.

Maize delivery, storage and cleaning

Maize is delivered to starch plants by water, rail or road. Deliveries are normally made on a daily basis but a 10-14 day buffer supply is normally maintained. Initial cleaning of the grain is carried out by first tipping the maize through coarse security sieves to remove any larger contaminants that may be present. The grain is then pneumatically transferred to a series of vibratory sieves and winnowing towers to remove both light and heavy contamination. Broken and damaged nibs must be removed at this stage as they are unsuitable for processing. These can be sold on directly or blended with other byproducts which are usually compounded for animal feed purposes. The clean maize nibs are then pneumatically transferred to holding silos to await processing.

Steeping

The first processing stage is steeping or soaking the grain in water. Steeping has two main purposes. First, it softens the grain to allow milling without shattering and second it brings the moisture content to the optimum for milling to be carried out and permits the gentle separation of the grain into its component parts. These can be placed in four constituent groups; the outer hull (bran or fiber), the germ, the maize gluten and the starch.

Maize is typically soaked for 30-50 h in stainless steel tanks holding 50-60 tons of product at 45-60°C using a counter-current process. High temperature/pressure processes are also used to reduce steeping times and volumes of steep water produced. The water contains added sodium metabisulphite as 0.1-0.2% sulfur dioxide and is inoculated with lactobacillus. Sodium metabisulphite is added for several reasons. It decreases the pH, it limits unwanted fermentation from putrefactive microorganisms and it promotes lactobacillus growth. This last point would appear to be of paramount importance in maximizing starch yield. It also acts in a disruptive way on the protein matrix in the endosperm allowing the maximum release of starch during the milling stage.

During the steeping process, the maize grains will absorb 5O% of their own weight of water and lose some 6% solids. This solid matter consists of soluble low molecular-weight sugars, proteins, low molecular-weight peptides, amino acids and minerals. The outflow steep stream is concentrated and sold as corn steep liquor to the fermentation industry or spray-dried onto maize gluten and sold as a solid for the same purpose.

Although the steeping process is discussed as a routine part of the wet milling process it must be pointed out that this stage is of considerable importance in terms of maximising the end yield of the starch and its physicochemical characteristics and is also important with respect to the quality of the corn steep liquor itself. Temperature/time changes during steeping will, for example, change the composition of the corn steep liquor. Since corn steep liquor is used in fermentation for secondary metabolite harvesting, qualities which lead to enhanced yields and optimum composition command a premium price.

Degermination

Degermination is the first stage of the separation process and is carried out by passing the soaked maize through primary attrition or pin mills. The milling surfaces have a series of interlocking pins which in fact do not mill as the name infers but rather gently tear the grains apart removing the hull and releasing the germ from the endosperm. The germ which contains most of the oil can be easily separated from the fibre, starch and protein components on the basis of its low specific gravity. Originally germ separation was accomplished in flotation tanks but now the process is carried out bypassing the process stream through multistage hydrocyclones. The germ fraction is removed as the overflow stream where it is washed several times to remove adherent starch and protein. The wash stream is added back to the process stream which then passes to a second milling stage. This removes any remaining germ from the maize kernel. A similar process of hydrocyclone separation and washing follows.

The separated germ is then dewatered and dried and may be sold for animal feed use or more commonly is deoiled on-site before being used for the same purpose. The dry germ contains 50-60% oil and the extracted and refined product is widely used domestically and commercially.

Fine milling

The underflow stream, post germ separation, then passes through a fine milling stage which produces a finely ground mixture of starch, gluten and fiber. This process must be very carefully controlled to ensure maximum size reduction of the protein and starch (without damaging the granule structure) but yet leave the fiber intact as far as is possible. This facilitates the separation of the fiber from the protein and starch and ensures minimum contamination of the starch stream with small fiber particles. The fiber fraction is sieved out using multistage bow sieves. It is then dewatered and dried and used for animal feed. This leaves a mainstream consisting principally of starch and gluten.

Gluten separation

The gluten-starch stream is then usually passed through a desanding hydro cyclone to remove grit and other heavy particles. The primary separation of the starch from the gluten is carried out using continuous high speed centrifuges which separate the lighter gluten fraction from the heavier starch. Thorough washing of the gluten to recover as much starch as possible is essential to give good starch yields from the process. The protein is used for animal feed as it lacks functionality and has a poor taste.

Starch refining

To obtain a high quality pure starch, the final stage of the process involves the washing of the starch to remove any remaining fiber, gluten and solubles via a counter-current, multistage hydrocyclone arrangement. The resultant starch stream is usually about 40% dry solids with a protein content less than 0.15% (dry basis). The starch from this stage can be fed directly to the first step of the glucose syrup conversion process or alternatively dewatered and flash dried to give maize or corn starch.

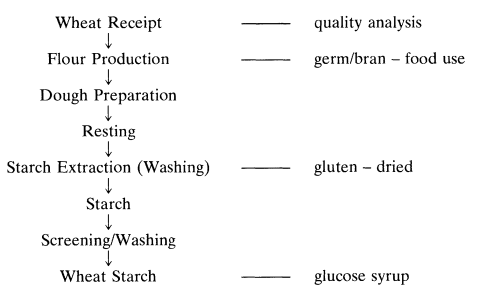

Wheat starch

Unlike the wet milling process for maize, wheat starch is manufactured not from whole wheat but from wheat flour obtained from a typical wheat milling process. The starch is generally not the main grain constituent of interest to the manufacturer but is rather of secondary importance after the wheat gluten. It is however an important constituent and its removal and subsequent use has a significant effect on the profitability of the wheat processor. The overall process for wheat starch production is shown in Figure 1.5.

In the flour mill the wheat is conditioned and subjected to repeated dry milling and sieving to remove the bran or fibre and germ. Oil is not usually extracted from the germ which is typically used intact for bread making. A dough is made from the flour by adding water and after a short resting period is washed extensively to separate the starch from the protein.

It should be noted that the wheat starch industry has evolved from the gluten industry. Initially wheat starch was produced as a byproduct of this process and the glucose syrup manufactured from it was often of poor colour and quality. The situation has now significantly changed with glucose syrups being manufactured from wheat starch to high specification. Furthermore owing to the high price of gluten and other considerations, wheat is now becoming a very attractive raw material for processing in Europe.

Dough preparation

Dough is usually made up in conventional Z-blade mixers of the type commonly used throughout the baking industry. Water is added to the dough at about 60% of the flour weight. After mixing, the dough is rested for about 20 min in order for the gluten matrix to develop and facilitate separation of the starch and protein.

Dough extraction

Post resting the dough is washed in gluten separators which are in effect continuous extractors. The separators are usually long cylindrical vessels housing multiple horizontally rotating paddle washers. The rested dough is fed via a top inlet falling to the bottom of the trough where it is moved and kneaded via the paddle action. Water is fed in at a constant rate at the bottom of the trough to maintain a level not far above the paddles. The washed out starch is held in suspension and removed at outlets at the top water margin at approximately 10% dry substance. In a continuous process the washed gluten is removed at one end of the extractor via an outlet auger.

Starch refining

The first stage of starch refining is carried out by screening the starch stream to remove residual bran and gluten. This can be done in a number of ways but is conveniently carried out by feeding the stream through what could be best described as large scale washing machines. The starch is washed out through cylindrical screens and the residual contamination of bran and gluten is taken out through a horizontal axis augar. The starch stream is then washed counter currently through multibank hydrocyclones to produce a starch stream which can be dried or thickened by centrifugation prior to feeding onto the conversion process.

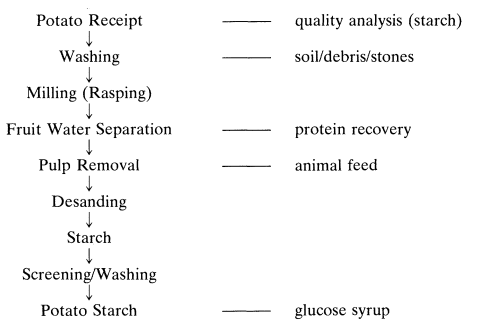

Potato starch

Unlike corn and wheat where material may be bought against internationally agreed quality specifications, potatoes are usually supplied by farmers local to the plant. The farmers are contracted to grow a specific acreage of potatoes and are supplied with seed potatoes of industrial quality. The harvested crop contains up to 20% starch compared with domestic potato varieties which contain about 10% starch. Supply from such a diverse group of producers means that the quality of the raw material will vary considerably, for example regarding contamination, residual soil, etc. and incoming potatoes at the factory must be closely examined.

Many statistics are quoted in the potato starch industry. These include the energy required to treat the waste which is equivalent to that required to extract the starch and in a potato starch plant half the surface area is required to process the waste (usually in a series of lagoons). It must be emphasised that environmental issues are a major problem and the plants efficiency and cost effectiveness will depend on the ability to recycle water and remove as much organic waste from the effluent stream as possible. The tonnage of water required to process one ton of potatoes must be as small as possible.

Delivery and cleaning

The overall process of potato starch production is shown in Figure 1.6.

Potatoes must be processed quickly after harvest or they will rapidly deteriorate, unlike maize and wheat which can be dried and stored almost indefinitely. A wide range of transport is used to deliver potatoes to the processing plant although road is the usual means owing to the local nature of the raw material. All deliveries are weighed and randomly sampled to assess the content of soil, stones and other debris. These contaminants are removed from the sample and weighed to form a measure of the ‘impurities’ in the product. The starch content of the potatoes is determined by weighing a known quantity of potatoes in air and water and calculating the starch content by reference to density tables.

After tipping the potatoes in a ‘dirty’ holding area they are taken into a water flume to sieves where floating vegetable matter and stones are removed. The potatoes are then washed in rotating drums were most of the dirt is removed by attrition. Many thousands of tons of soil, stones and vegetable matter are produced during a typical campaign and the weather at harvest of the potatoes is important with respect to the quantities of these components in the potatoes. The potatoes are then stored in a clean potato area ready for processing.

Rasping, extraction and refining

Potatoes are a relatively pure starch source and can be processed fairly simple. They are first milled by gravity feeding onto rotating rasping saws which reduce the potatoes to a pulp. This process must destroy the structure of the potato and free the starch from the other constituents without damaging the starch granules or producing too fine a pulp. The pulp is passed over magnets to remove any possible metal contamination from the rasping stage. Sodium meta-bisulphite is added to limit enzymic browning and metal complexing reactions which may occur. The potato pulp is then passed to a slurry tank where as much fruit water as possible is removed by decantation.

Antimicrobial agents may also be added at this stage to reduce the numbers of microorganisms in the finished product. The starch stream is purified to remove any heavy debris, fibre and soluble matter by subjecting it to repeated cycles through multibank hydrocyclones. The final step involves washing the starch counter currently with conditioned water. The starch stream may then either be dewatered to 60-65% solids on rotary vacuum filters and dried or concentrated to 30-40% solids for feeding onto conversion into glucose syrups. Potato fibre and protein may also be recovered during the process of starch manufacture. Although these constituents are not present in large quantities in potatoes, over a campaign, where many hundreds of thousands of tons of potatoes are processed significant quantities are recoverable. Typically these components are used for animal feed. The fruit water is a particularly good source of soluble protein which can be recovered by heat coagulation.

Tapioca starch

Tapioca is a common starch source in Brazil, Thailand, Malaysia, Indonesia and Nigeria. The processing of tapioca follows a very similar process to that for potatoes. Both crops have high water contents and have to be processed as soon as possible after harvest. The tapioca root varies widely in size between about 20-75 cm in length and is also covered with a skin that is removed prior to processing. The peeled roots are cut into thin slices prior to grinding in the rasping mill. The tapioca slurry is then subjected to a similar processing regime as potato slurry. The process is shown in Figure 1.7.

In many of the countries which use tapioca as a starch source, roots are available all year round and processing is therefore virtually non-stop. The quality of the roots and particularly their composition will vary over the year, however, with starch contents for example ranging from 13% to 25% over the processing period. Viscosity of the extracted starch also changes markedly over the campaign period.

Farmers are paid according to the starch content of the tapioca and there is obviously some reluctance among farmers to bring low starch content roots to the factory just to keep the factory running. Where the country has a wet season, actually harvesting roots may be impossible and factories have no option but to stop production of starch. A further complication with tapioca roots is that some varieties contain appreciable quantities of cyanide and care must be taken to ensure the starch is washed thoroughly to remove all traces.

Although the production techniques for tapioca starch are very similar to those for potato starch, tapioca starch production is not as well developed as potato starch. For example, the pulp removed from the roots and sent for animal feed contains up to 55% starch which is a considerable loss of revenue.