The potential of cassava flour to diversify markets for cassava producers is investigated. The effects of different root processing regimes on cyanogen contents and microbiological counts—major factors governing quality in cassava flour—were investigated at CIAT. Chipping, rasping, and different drying technologies were evaluated in terms of product quality. Three types of chippers, five raspers, and drying by sun, oven, or bin were used. Rasping and drying reduced the cyanogenic glucoside contents of the roots by 90% to 100%, but microbiological counts were high for all drying technologies. The chipping trials indicate that sun drying on trays produced chips of similar microbiological quality to artificial drying.

Introduction

Cassava is grown in many parts of the developing world, mainly by small-scale farmers, for both food and income. Often such farmers have limited scope for other crops, because of harsh climate, poor soils, or both. Markets for fresh roots for direct consumption are stagnant or diminishing in many places because of increasing urbanization and changes in eating habits. Demand for roots for starch and chips for animal feed, although existing where such industries operate, is limited. Cassava flour is a product that could help diversify and strengthen cassava markets for these small producers.

The main industrial market opportunities for cassava flour are in the substitution of other raw materials, primarily wheat flour or starches, for further processing into final products. In some areas, smaller regional markets exist for local, cassava-based food specialties. To penetrate these markets, cassava flour must be of at least comparable quality to the product it is potentially replacing. Possible clients are unlikely to risk changing feed stocks if it is at all possible that the quality of their end product will be adversely affected.

Factors of Flour Quality

Microbiological quality

Wheat flour tends to be of high microbiological quality, because the economic product (the grain) develops above the ground; is cultivated with modern, large-scale, farming practices; and is harvested at relatively low moisture content. In contrast, cassava roots are usually cultivated with basic farming practices, picking up a microbial load from the soil, and have a much higher moisture content than grains. Hence, cassava flour is likely to have higher levels of microbiological growth.

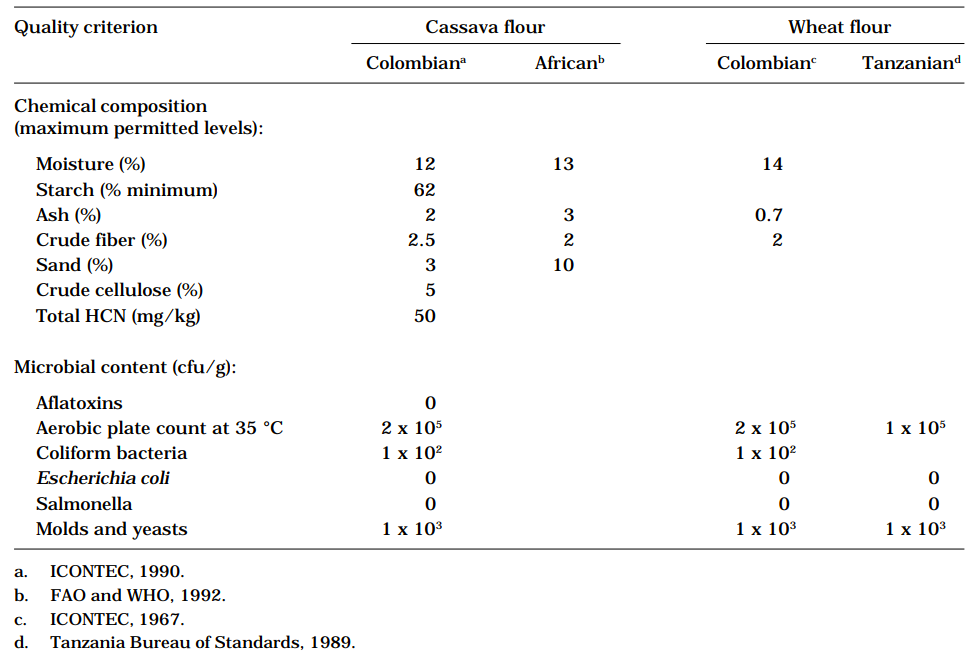

Table 1 gives selected flour standards. The Colombian standard permits the same maximum bacterial loads for both wheat and cassava flours. Cassava flour has a lower maximum permitted moisture than wheat flour, because of its perceived greater susceptibility to contamination.

Cyanogens

Cassava flour also contains residual levels of cyanogenic compounds (cyanogens), mostly cyanogenic glucosides (CG), cyanohydrins, and hydrogen cyanide (HCN). The glucosides initially present in the fresh roots are broken down, during processing, to the other cyanogens given above (Bokanga, 1992). Cyanogen concentrations are expressed as mg HCN equivalent per kg of dry matter, unless otherwise stated. Nonglucosidic cyanogen (NGC) concentration describes the combined concentrations of cyanohydrins and HCN. The cyanogen levels remaining vary with the raw material concentration and the processing technologies employed (Fish and Trim, 1993). These levels are not a major concern for nonfood use.

Hydrogen cyanide is toxic, but is usually present only in small quantities because of its volatility. Evidence suggests that cyanide poisoning and intoxication resulting from consumption of cassava flour may be caused by high residual cyanohydrin levels, which then decompose after ingestion (Banea, 1993; Mlingi et al., 1992). The effect of consuming CG on health is less clear and has not yet been thoroughly investigated.

Few official standards exist specifically for cassava chips and flour for human consumption. The Colombian standard for dried cassava sets a maximum total cyanogen content of 50 mg/kg (fresh basis), measured as HCN (ICONTEC, 1990). The regional standard being developed for Africa (FAO and WHO, 1992) sets a maximum total cyanogen content of 10 mg/kg (fresh basis). The standards are expected to evolve with the product, and further guidance may be found in the proceedings of the Cassava Safety Workshop held in 1994.

Research on Processing Technologies

The quality of the cassava flour produced at the CIAT pilot plant was rigorously evaluated in terms of residual cyanogens and microbiological quality (results not shown). Research was then carried out at CIAT, with the following objectives:

- To investigate the modification of chip size as a means of increasing the elimination of total cyanogenic potential (CNP) during flour production. The degree of cyanogen elimination achieved by the pilot plant effectively sets the maximum initial cyanogen concentration in the feed roots acceptable by a plant of this type. Increasing the elimination of cyanogens without fundamentally changing the process would ensure that the cassava flour produced meets the standard, and would increase the range of varieties that the plant’s processing operations can satisfactorily detoxify. Manually peeling the roots was not investigated at this stage.

- To investigate means of processing high cyanide varieties of cassava into flour with safe residual cyanogen levels. High cyanogen varieties are more suited to some agroecological zones, and are preferred to low cyanogen varieties in some regions. The operations of chipping and drying do not eliminate enough cyanogens to process high cyanogen varieties satisfactorily.

Effect of Chip Size on Residual Cyanogens in Bin-dried Chips

Methods

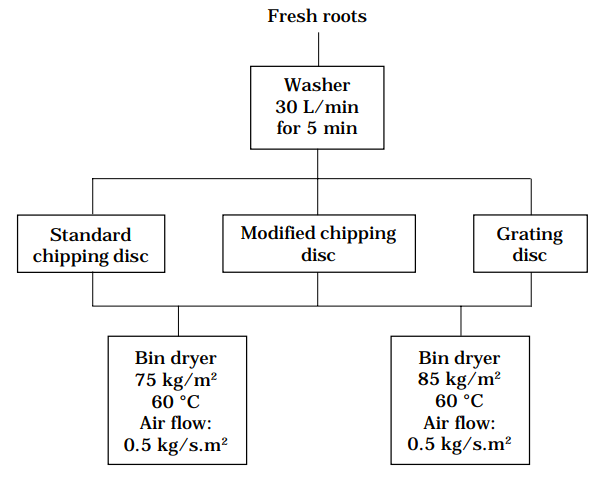

Trials were carried out with three different chipping disks: the standard disk (CIAT-designed); a modified version with reduced chip aperture to give thinner chips; and a grating disk designed by the Ecole nationale supérieure des industries agricoles et alimentaires (ENSIA), France (Monroy-Rivera, 1990). Roots 11 months old were harvested the day before the trial and stored outdoors overnight (normal factory plant practice). The roots were washed in a drum washer, which also effectively dehusks the roots, and chipped. The wet chips were bin-dried at 60 °C, at loading densities of 75 and 85 kg/m2 (Figure 1). Six samples were taken from both fresh and dried chips, and analyzed with the modified Cooke method (O’Brien et al., 1991).

Results

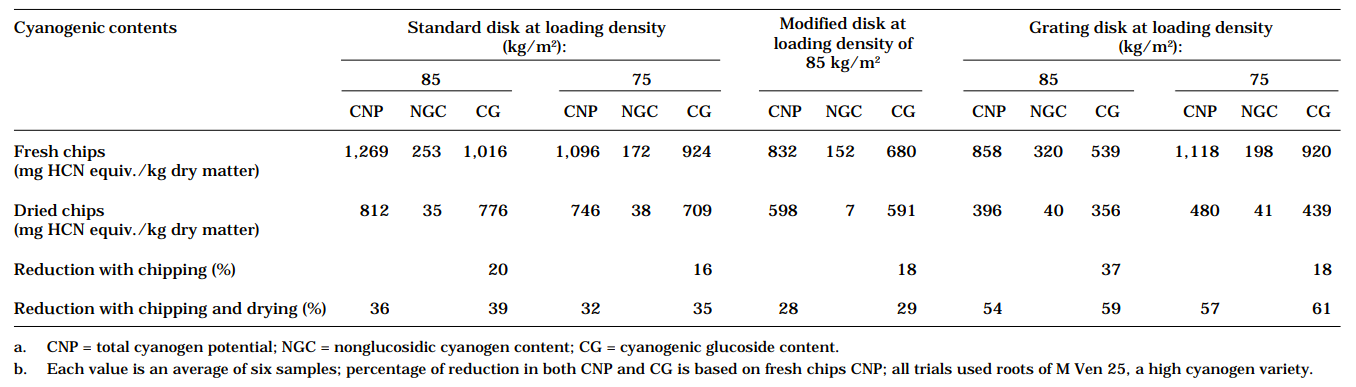

Table 2 gives the cyanogen contents measured during these trials.

Standard disk. The total CNP in the fresh chips were reduced by about 34% by chipping with the standard disk, followed by drying within 5 hours. This figure is consistent with the results obtained by using the same disk at the pilot plant, where proportionally greater reductions in CNP were achieved with longer drying times. This was despite processing a different variety under different climatic conditions.

Modified disk. The modified disk achieved a similar level of reduction in CG, but with a lower overall CNP reduction of 28%.

The modified chips had an average thickness of 4.3 mm, compared with 6.1 mm for the normal chips, providing a greater cut-surface area. A greater initial elimination of the CG was therefore expected in the modified fresh chips because of the higher percentage of damaged root tissue. Under suitable conditions, a faster drying rate was also expected, leading to surface drying of the chips in a shorter period, and earlier termination of cyanogenic reactions.

The low degree of elimination obtained with the modified chips indicates that the effect of fast drying is masking any effect of chipping, which would be more obvious at the slower drying rates obtained at higher loading densities.

Grating disk. The grating disk showed a higher reduction (56%) than the standard chipper (34%) of CNP, with chipping and drying. This is consistent with the greater extent of tissue damage achieved. Reduction of CG with chipping and drying was consistent at 59%-61%. The reduction in CG is dictated by the quantity of glucosides brought into contact with linamarase enzyme, which, in turn, depends on the extent of tissue damage. Cyanogenic glucosides in undamaged tissue remain intact. The chips produced by the grating disk were more fragile than the pilot plant ones and less suitable for bin drying.

Summary

Elimination of CNP from chips made by the standard disk increased with drying time, regardless of cassava variety or location.

The grating disk eliminated 22% more CNP than the pilot plant disk at the same loading density. Grated chips, however, are more fragile than standard chips and less suitable for bin drying.

Effect of Different Raspers on Residual CNP in Tray-Dried Pulps

The effect of different raspers on the degree of cyanogen elimination achieved with rasping and drying was investigated. Rasping almost completely destroys the root tissue structure, much more so than chipping. The trials used roots of M Ven 25, a very high cyanogen variety, to establish the upper limits of cyanogen elimination.

Methods

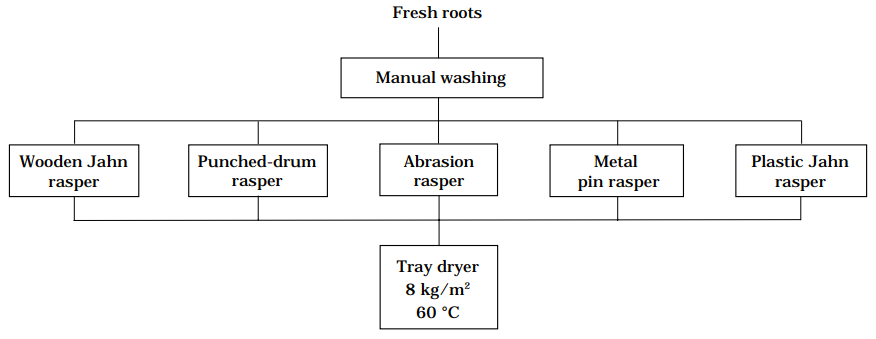

Five different raspers were used:

- A conventional, wooden Jahn rasper, in which serrated blades are mounted laterally on a wooden drum.

- A punched-drum rasper, consisting of a metal sheet with outward facing jagged holes (punched through with a nail), fixed around a wooden drum frame.

- A pin rasper (experimental), a metal drum scored diagonally in both directions across its length with metal pins protruding about 5 mm from the drum’s surface.

- An abrasion rasper (experimental), with a layer of carborundum, about 10 mm deep, fixed around a drum.

- A plastic, Jahn rasper (experimental), in which metal serrated blades are mounted laterally on a plastic drum.

Four of the rasper drums tested were interchangeable within the same rasper frame, designed to investigate their relative starch extraction efficiency. The drums were 400 mm in length and 270 mm in diameter. The plastic Jahn rasper drum was a smaller, self-contained unit, 275 mm in length and 200 mm in diameter. An ordinary 5-HP motor was used for all the raspers. The wooden Jahn rasper and the punched-drum rasper are in common use in the cassava starch industry.

Roots were harvested at 9 months and stored as for the chipping trials. The roots were washed in clean but untreated water and dehusked manually. Fifteen kilograms of the washed roots were rasped without adding water. The resulting pulp was mixed and dried at 8 kg/m2 on two trays in a despatch tray dryer at 60 °C (Figure 2). Four samples each of the fresh and dried pulps were taken for evaluation of cyanogen concentrations. This procedure was followed for each rasper.

Results

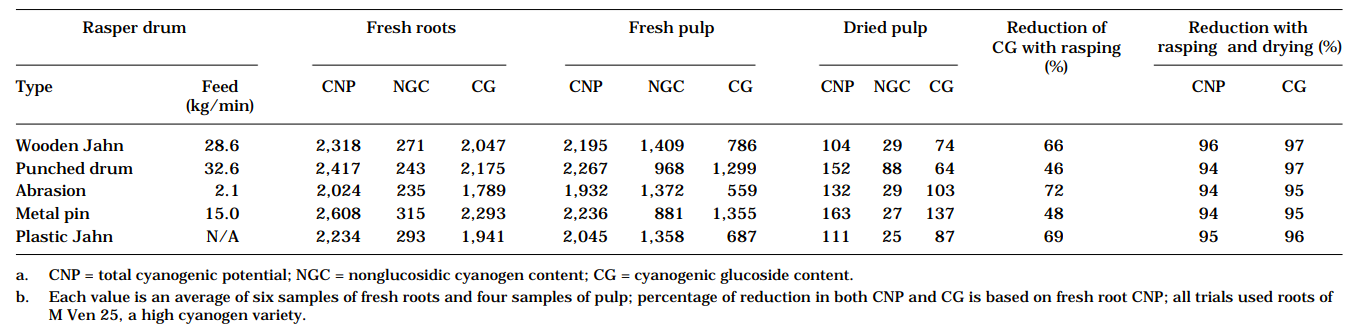

Table 3 gives the cyanogen concentrations measured during this trial.

Cyanogen contents of rasped pulps. The reduction in CG with rasping only was variable, with both the Jahn raspers reducing the CG by 65%, and the punched drum by 43%. When the pulps were both rasped and dried, the CNPs were reduced by 94%-96% for all raspers, regardless of the degree of reduction effected by rasping alone. The residual CNPs in the pulps ranged from 104 to 163 mg/kg. In previous milling trials, the residual CNP concentration in first-grade flour was about 36% of the level in freshly dried chips. Assuming this to hold true for pulps, the flours would have CNPs between 38 and 58 mg/kg, thus mostly meeting the Colombian standard of 50 mg/kg.

This level of total cyanogen elimination probably approaches the maximum possible in practice, given that variations occur because of fluctuating conditions. No significant differences in the overall elimination of CNPs was found between the raspers.

Root throughput. The abrasion rasper’s root feed was 10% below that of the Jahn or punched-drum raspers, thus making it unsuitable for commercial flour production. The shredding action employed by both the Jahn and punched-drum raspers removes a deeper layer of root tissue with each contact than does the erosive action of the abrasion rasper, resulting in a larger root feed.

The pulp produced by the abrasion rasper was finer and more homogenous than the other pulps, indicating a greater degree of tissue comminution. However, the final reduction in CNP achieved with the abrasion rasper was not significantly different to that achieved with the other raspers. The pulp was also more liquid and difficult to handle than the others.

Summary

Except for the abrasion rasper, the raspers evaluated were suitable for processing roots with high cyanogen contents to flour with low cyanogen content. The wooden Jahn and the punched-drum raspers are commercially available.

Effect of Different Drying Techniques on Residual Cyanogens and the Microbiological Quality of Dried Pulps and Chips

The effects of different drying techniques (sun and artificial) on the microbiological quality and on the cyanogen concentrations of chips and rasped pulps were evaluated.

Rasped pulp is not suitable for bin drying, and the effect of rasping on the microbiological quality of the dried product is unknown. Because smaller operations may not be able to justify the investment and cost of artificial drying, the effect of sun drying on the microbiological quality of products was also evaluated.

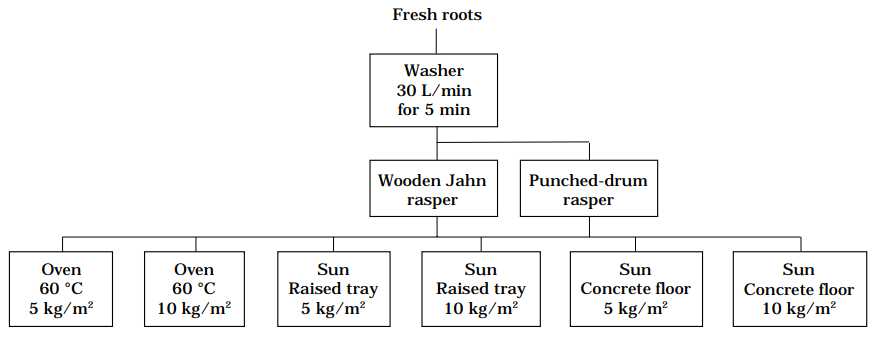

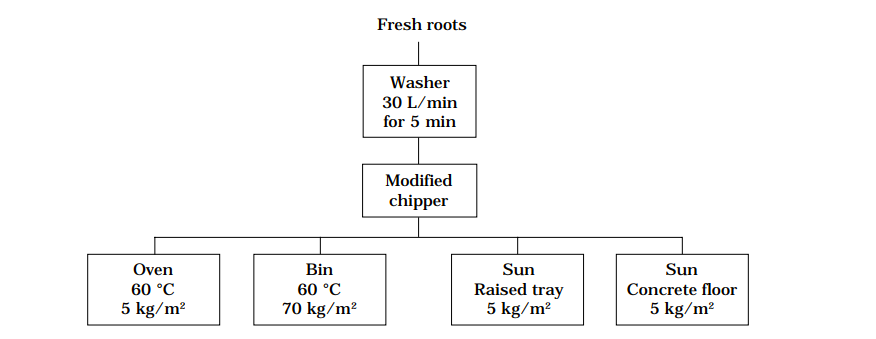

Methods

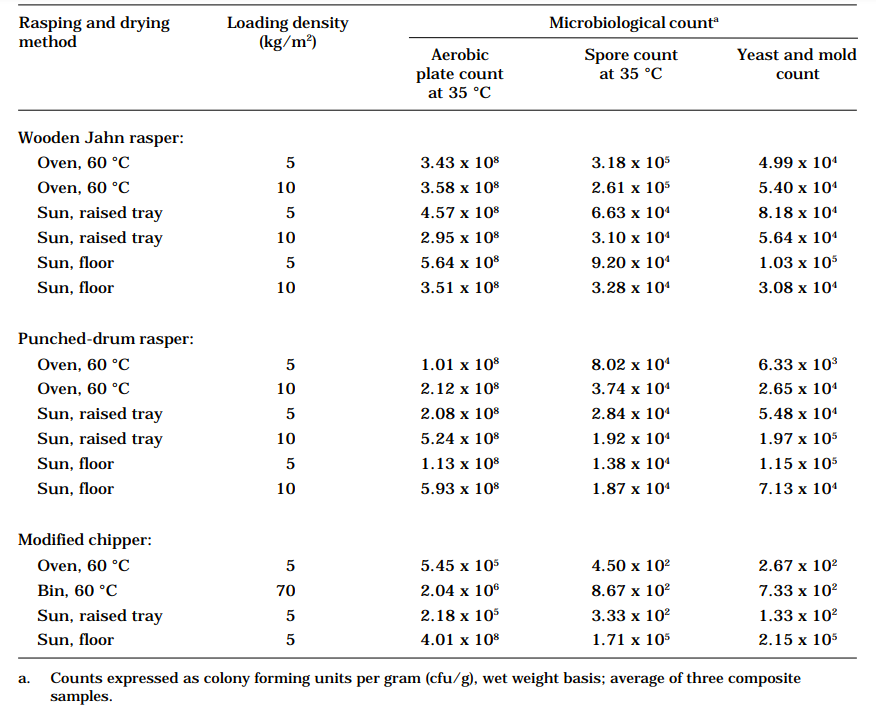

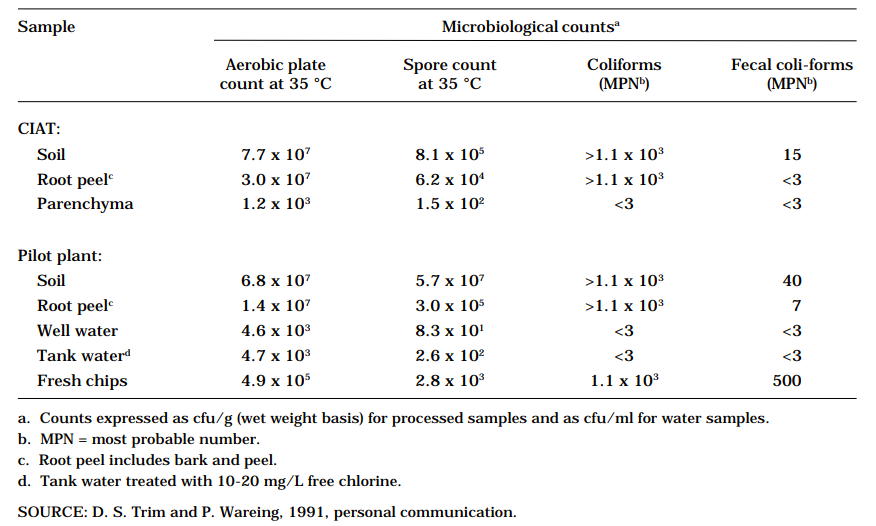

Three trials were carried out on 10-month-old roots of cassava variety M Ven 25. The first two trials used the wooden Jahn and punched-drum raspers for root comminution. The roots were washed and dry-rasped as in the rasping trials described above. The pulps were dried at loading densities of 5 and 10 kg/m2 on raised trays and on a concrete floor in the sun, and in an oven at 60 °C. The final trial was carried out with the modified chipper, with the chips dried at 5 kg/m2 in the same way (Figure 3). Chips were also bin-dried at 70 kg/m2 and 60 °C (Figure 4). The chips and pulps were mixed manually every 2 h during drying. Three composite samples of each dried product were taken for microbiological analysis. The samples were analyzed for aerobic plate counts (APC) (35 °C), spore counts (35 °C), and yeasts and molds the following day (ICMSF, 1978). Four samples each of the fresh and dried pulps were also taken for cyanogen evaluation.

Results

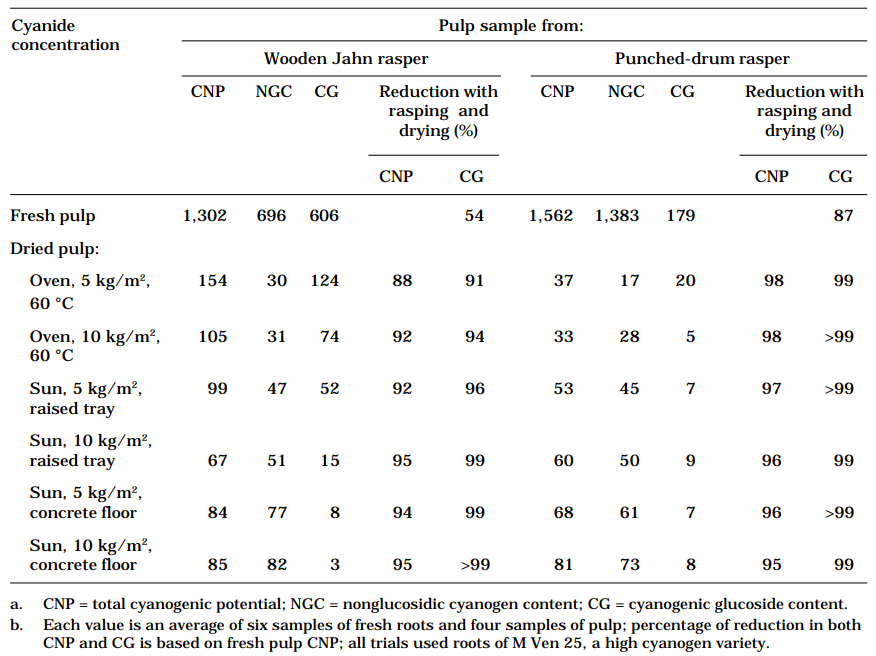

Table 4 gives the cyanogen concentrations measured during the trials and Table 5, the microbiological counts.

Cyanogenic contents of dried chips and pulps. Compared with the rasping-only trials, the punched drum reduced CG (88%) more than the wooden Jahn rasper (53%). Rasping and drying reduced the CG by 90%-100%. Sun-dried pulps tended to have higher residual NGC than did oven-dried pulps, possibly because of the higher rate of removal of HCN during forced-circulation oven drying, which would increase the rate of breakdown of cyanohydrin to HCN. Residual cyanohydrin levels tend to drop with storage and may also be reduced by the heat generated by milling to flour.

Microbiological quality of dry pulps and chips. All of the dried, rasped, pulp samples had high APCs (108 cfu/g), as did the chips which were sun dried on a concrete floor. The oven-dried, and raised-tray, sun-dried chips were of acceptable quality (105 cfu/g), and the bin-dried chips had only slightly higher counts. The rasped pulps provide a better substrate for microbial growth than the chips, as the cell contents (e.g., sugars and proteins) have all been released by rasping.

However, the APCs of fresh chips have been measured at around 105 cfu/g (Table 6). Previous pilot-plant experience has shown that, with long drying times (22 h), the APCs of the chips are at 108 cfu/g, but reducing the drying time to 10 h reduces the APCs to 105 cfu/g. Faster drying of the pulp may therefore offer a means of reducing the counts. The shortest pulp drying time of 6 h was insufficient to affect the counts.

Raised-tray sun drying of chips gave a product of good microbiological quality with APCs similar to those of oven-dried chips. Thus, this method may have potential for reducing costs under suitable climatic conditions (site specific).

Summary

Rasping and drying of cassava roots is an effective means of reducing the CNP present in high cyanogen cassava varieties. However, the greater degree of root disintegration leads to increased microbiological growth.

Conclusions

Processing with the grating disk reduced CNP by 22% more than the standard disk. However, drying grated chips at high loading densities may be difficult.

Fast drying stopped the elimination of cyanogens early in the drying period of the modified-disk chips, masking any effect chip size might have had. Greater reduction in CNP is likely at higher loading densities. Rasping and drying is an effective means of processing even very high cyanogen roots to a flour that meets the Colombian standard. Further work is needed to improve the product’s microbiological quality. In suitable climatic conditions, raised-tray sun drying of chips gives a product of good microbiological quality.