Fermented or “sour” starch extracted from cassava is used in Colombia to prepare traditional, gluten-free, cheese breads such as pandeyuca and pandebono. Starch extraction consists of peeling, washing, and grating fresh cassava roots. The pulp is then screened under running water to obtain starch milk or lechada. The starch is then sedimented out and placed into wooden or tiled tanks (about 1 m3), where it ferments naturally over 20 to 30 days under anaerobic conditions and at an average temperature of 21 °C. The resulting sour starch is then sun-dried to obtain a stable product with 10%-15% moisture, and is marketed (Brabet and Dufour, 1996; Jory, 1989).

Bread-making potential (BMP) is the main criterion of quality for sour starch and is defined as the ability of the starch to swell during baking (Laurent, 1992).

Although quality and rapidity are two major issues in cassava starch production, sour starch is still produced according to traditional methods. Hence, sour starch is highly variable in product quality, limiting its use in food industries.

Fermentation and sun-drying critically influence the BMP of sour starch (Brabet and Dufour, 1996; Larsonneur, 1993). Developing adequate control of and suitable practices for these two processing steps would help stabilize and improve sour starch’s economic value and strengthen the status of this agroindustry.

Cassava processors sometimes improve sour starch quality by inoculating batches with surface water from fermentation tanks in which good quality products have been produced. But this practice still results in irregular quality of sour starch.

We therefore studied the natural fermentation of cassava starch in detail, in an attempt to relate the nature of microflora and their effect on final product quality. We then carried out a cassava starch inoculation trial, using amylolytic lactic acid bacteria (ALAB), isolated and selected from previous fermentation kinetic studies. Our purpose was to standardize product quality and reduce fermentation time.

We also carried out studies to confirm the role of sun-drying in the acquisition of BMP, and to determine the key factors responsible. The trials involved sun-drying kinetic studies, oven-drying at 40 °C and at 55 °C, drying under cover, oven-drying at 40 °C under ultraviolet (UV) light, and drying with water added.

Cassava Starch Fermentation

Natural fermentation

Natural fermentation of cassava starch is characterized by the presence of a predominantly lactic acid flora (108-109 cfu/g dry matter of starch), confirmed by the rapid and drastic decrease of pH (7 to 3.5 in 5 days), while total acidity increases because of a mainly lactic acid production (Brabet and Dufour, 1996). Lactic acid flora has an active catabolism but its level is constant during fermentation.

At the start of fermentation, starch is the main source of fermentable sugar. Gómez (1993) isolated 75 lactic acid bacterial strains, exhibiting good amylolytic activity, from natural cassava starch fermentation. This ALAB strain bank is currently being molecularly and biochemically characterized.

Previous works have shown modifications of cassava starch physicochemical and rheological characteristics during fermentation (Brabet and Dufour, 1996; Brabet and Mestres, 1991; Camargo et al., 1988; Cárdenas and de Buckle, 1980; Larsonneur, 1993; Nakamura and Park, 1975).

Effect of a starter culture on cassava starch fermentation and quality

A fermentation with starch inoculation was carried out at the “SDT Agroindustrial,” a starch-processing plant in La Agustina, Cauca Department, Colombia, using cassava variety CM 523-7. An amylolytic lactic acid bacterial strain, ALAB 20, used for the starch inoculation trial, was isolated from a previous natural cassava starch fermentation and identified as Lactobacillus crispatus, using the Gómez (1993) API 50CH system. Flores (1993) studied the physiological parameters of this ALAB 20 strain during a lactic acid fermentation on an MRS-starch medium in a bioreactor. (The glucose in the medium was replaced by soluble starch.)

The fermentation tank was partitioned into two: one part for natural fermentation and the other for inoculated-starch fermentation. Inoculated and noninoculated lechadas (aqueous starch suspensions) were first sampled. Then, samples of inoculated and noninoculated starch were taken at 1, 2, 3, 4, 5, 7, 10, 14, and 20 days of fermentation.

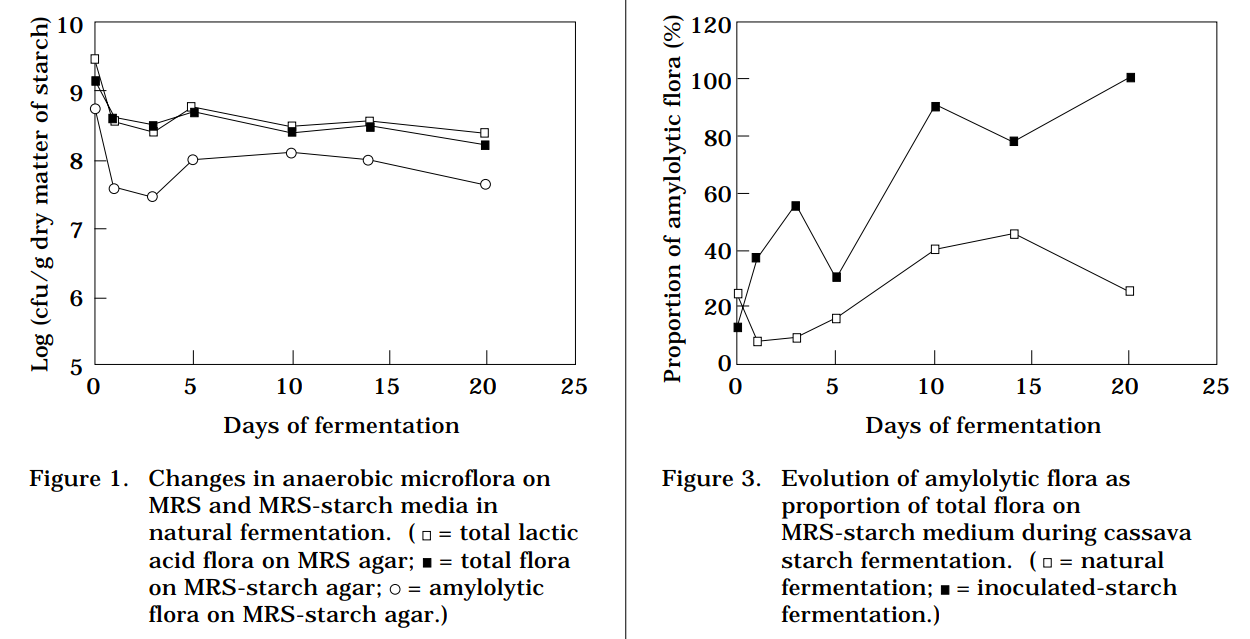

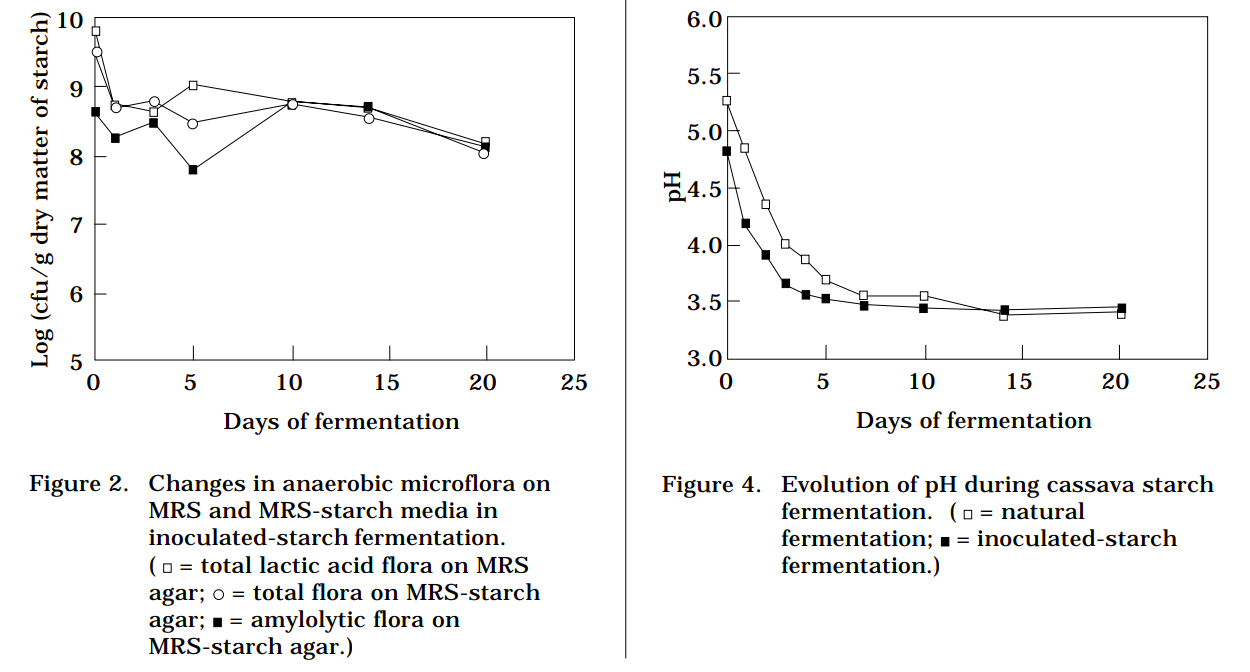

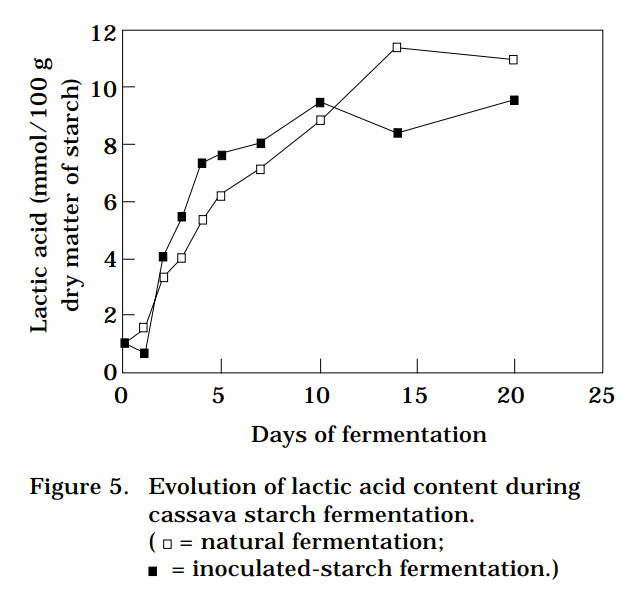

Changes in amylolytic and total lactic acid flora. Total lactic acid flora on MRS medium showed no significant difference between inoculated and noninoculated starch (Figures 1 and 2). This flora reached 108-109 cfu/g of dry matter of starch on the second day and remained constant until the end of fermentation. In contrast, as a proportion of total flora, amylolytic flora on MRS-starch medium (MRS medium where glucose was replaced by 20 g/L of soluble starch) were in a higher proportion in inoculated starch than in noninoculated (Figures 1, 2, and 3). Furthermore, flora were heterogenous during the natural fermentation, whereas the inoculated fermentation resulted in a predominance of the ALAB 20 strain.

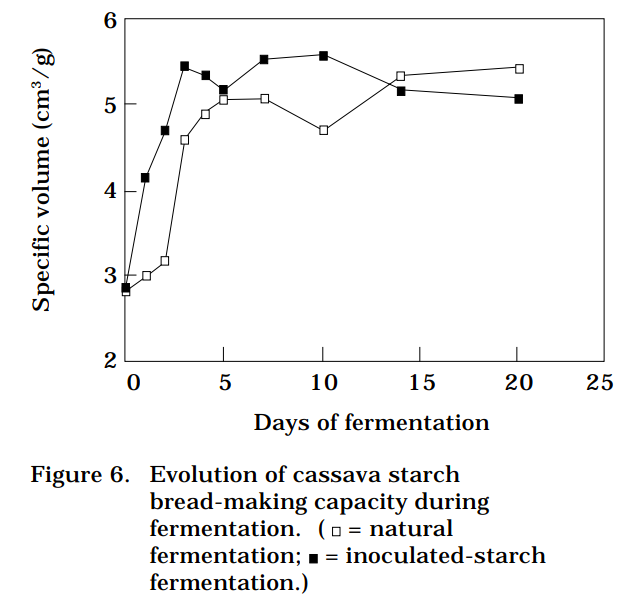

pH and lactic acid production. In the inoculated-starch fermentation, acidification was more notable during the first 5 days of fermentation, but pH value finally stabilized at 3.5 (pKa of lactic acid) in both fermentations (Figure 4). The inoculated fermentation produced slightly more lactic acid (Figure 5) during the first days of fermentation.

Bread-making potential of starch. Inoculation of cassava starch with ALAB 20 allowed the final BMP to be reached 10 days earlier, compared with natural fermentation. But the final BMP of the starch was not improved (Figure 6).

Sun-Drying Cassava Sour Starch

Importance of ultraviolet radiation

Kinetic studies of drying cassava sour starch in the sun (8 h) were realized. Sour starch specific BMP increased from 2 cm3/g (wet starch) to at least 5 cm3/g in 4 h of sun-drying (Larsonneur, 1993). The same starch sample, when oven-dried at 40 °C (slow drying) or 55 °C (rapid drying), or dried under cover for 8 h, did not expand (specific BMP of 2-2.5 cm3/g).

These results demonstrate the need for sun-drying if sour starch is to acquire BMP, and the importance of solar radiation. The results also explain why Brazilian plants producing cassava sour starch do not artificially dry starch during the rainy season but ferment it instead for various months until the dry season arrives.

Oven-drying trials of sour cassava starch at 40 °C and under a UV lamp (Cole-Palmer, G-09817-20, 4 W, 254 nm and 366 nm) were conducted for 8 and 16 days. Under UV radiation, the sour starch’s capacity for bread making increased to a value close to that of the sun-dried starch control, whereas oven-dried samples expanded little:

Bread-making potential (cm3/g) at: 8 h/ 8 days/ and 16 days

| Treatment | 8 h | 8 days | 16 days |

| Sun-drying | 6.82 | 6.82 | |

| Oven-drying at 40 °C | 2.46 | 3.18 | |

| Oven-drying at 40 °C and under UV: | |||

| 254 nm | 3.94 | 4.95 | |

| 366 nm | 3.78 | 4.75 |

These results show that UV radiation is one of the different types of sun radiation able to develop the BMP of cassava sour starch. Compared with 8 h of sun-drying, the lengthy period (8 and 16 days) needed to increase the bread-making capacity of sour starch may be explained by the low power (4 W) of the UV lamp used.

The role of water in sun-drying sour starch

Water content of cassava sour starch during sun-drying plays an important role in improving the starch’s bread-making capacity. For example, cassava sour starch oven-dried at 40 °C for 8 h, then rehumidified to 50% and sun-dried for another 8 h, had a higher bread-making capacity (5.10 cm3/g) than the same starch sample dried under the same conditions but without the additional water (3.75 cm3/g).

Better results are obtained (7.4 cm3/g) if sour starch is sun-dried at 40 °C for 8 h, then sun-dried for another 8 h, but with water added every hour for 3 h. In contrast, the expansion of the starch in the sun-dried control (8 h) was 5.03 cm3/g.

Conclusions

To improve the quality of cassava sour starch, the following recommendations should be made to the rallanderos (cassava sour starch producers):

- To ferment. Starch should be fermented for at least 20 days. The pH should be controlled at 3.5. The fermentation tank should be covered with about 5 cm of water to ensure anaerobic conditions and lactic acid fermentation.

- To dry. Sour starch should be dried under sunny conditions. Starch samples should be turned over to ensure exposure of all starch granules.

The preliminary results of starch inoculation trial demonstrated that the use of ALAB 20 as a starter culture helped reduce fermentation time. Replicated starch inoculation trials, using the same strain, will be undertaken to confirm these results. Other lactic inocula will also be investigated for reducing fermentation time and improving cassava sour starch quality.

From the results cited above, the concept of an artificial drying apparatus, using UV radiation and controlling starch moisture, can be visualized. This would make standardizing sour starch drying and quality possible, which would no longer be at the mercy of the weather.

Studies are being conducted to evaluate the influence of cassava variety and root storage on sour starch quality. Climatic conditions and the water used during production may also have effects.