Acceptable snack-type extrudates were produced, using flour from cassava (Manihot esculenta Crantz) as the main ingredient. Various formulas of cassava flour blended with other ingredients were tested. Extrusion processing was carried out, using a laboratory extruder (Wenger X-5, single-screw) under constant conditions, where feed moisture was 11%, barrel temperature 120-125 °C, screw speed 520 rpm, and feed rate 250 g/min. Sensory attributes of color, flavor, and texture, and overall acceptability were rated by panelists on a 5-point scoring system. Analysis of variance indicated significant differences (P < 0.01) for sensory attributes and for formulas. Flavor scored the highest, reflecting the presence of popular spices in the blends. Formula F4 received the highest scores for flavor and color and for acceptability. All formulas were acceptable, except for F7 and F8, which contained yeast. Color was most attractive when 0.1% turmeric was added.

Introduction

Cassava (Manihot esculenta Crantz) is grown mainly in tropical developing countries where it is a primary source of carbohydrates for millions of people (Coursey, 1978; Nestel, 1973). The roots do not store well after harvest and usually begin to deteriorate within 2 to 4 days (Odigboh, 1983). Processing helps solve the storage problem (Sammy, 1971) and increases the usefulness of cassava.

Snack foods now comprise an important part of the daily nutrient and calorie intake of many consumers. They can be sweet or savory, light or substantial, and may even be endowed with attributes such as “healthy” or “just for fun” (Tettweiler, 1991). Among West Indians, spicy snacks are especially popular.

Extrusion processing is one of the fastest growing, and most important, food-processing operations of recent years (Harper, 1981a; Paton and Spratt, 1984). The food industry has invested considerable research in the extrusion processing of a wide range of foodstuffs, developing many successful products (Linko et al., 1981), including snacks, baby foods, cereals and starches, and/or vegetable proteins (Harper, 1981b).

Cooked, extruded snacks are generally prepared from cereals such as de-germinated maize meal, and rice and wheat flour (Smith, 1976).

In Trinidad and Tobago, maize meal is a major imported ingredient for extruded foods such as ready-toeat snacks. Limited work has been done on the extrusion of cassava, resulting in the absence of cassava extrudates on the local market. The objectives of this research were to (1) use cassava flour as the main ingredient for a snack product under suitable processing conditions, and (2) determine, by sensory evaluation, the acceptability of extrudates of various formulas.

Materials and Methods

Feed ingredients

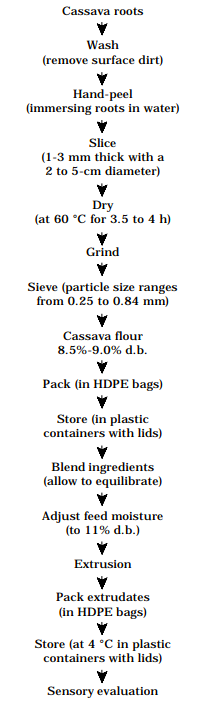

Cassava roots of the local variety ‘Maracas Blackstick’ were processed into flour (Figure 1) within 48 hours of harvesting. The flour was then blended with small amounts of additional ingredients to yield a variety of formulas. These ingredients were powdered spices, such as onion (0.2%, 0.5% w/w), garlic (0.2%, 0.5%), chili (0.2%, 0.5%), turmeric (0.1%, 0.2%, 0.5%, and 1.0%), and paprika (0.2%, 0.5%); sucrose (0.5%); uniodized salt (1.0%, 1.5%); monosodium glutamate (MSG, 1.0%), dried skimmed milk (0.5%); soybean oil (4.0%); yeast (1.0%, 1.5%), and defatted soybean flour (5.0%, 10.0%).

The feed sample of each formula was left to equilibrate for 24 h and adjusted to the targeted feed moisture of 11% d.b. The samples were again left to equilibrate at 4 °C for 24 h and, before extrusion, were allowed to reach ambient temperature. After cooking, the extrudates were packed in high-density polyethylene (HDPE) bags and stored at 4 °C in sealed plastic containers. Extrudates were presented to panelists for sensory evaluation within 2 days of extrusion.

A single-screw laboratory extruder, with a 2.5-cm diameter, was used (Wenger X-5, Wenger Manufacturing Company, Sabetha, Kansas). The screw was of decreasing pitch with a compression ratio (channel depth in feed zone to channel depth in metering zone) of 2:1 and length to diameter (L/D) ratio of 15:1. The die diameter was 5.0 mm and land length 9.0 mm. The die plate was attached to a breaker plate, 6.0 mm thick. The extruder consisted of eight stainless steel, jacketed head sections. Each section in the barrel was uniformly supplied with steam generated from a Sussman Electric Boiler (Hot-Shot Model, MB-6, Automatic Steam Corporation, NY). Barrel temperature was monitored by thermocouples mounted inside the barrel, using a temperature recorder (Type BD41, Kipp and Zonen, Holland). A feed hopper with paddle agitator ensured uniform feed flow into the extruder barrel.

Extrusion conditions

Badrie and Mellowes (1991b) had already established suitable extrusion conditions for cassava flour: blends should be extruded at constant conditions of feed moisture 11% d.b., barrel temperature 120-125 °C, screw speed 520 rpm, and feed rate of 250 g/min.

Proximate analysis

The proximate composition of cassava flour and the crude protein (%) of defatted soybean flour were determined by AOAC (1965) procedures, except for crude fiber (AACC, 1983). Total carbohydrate was determined by difference. Amylose was estimated with a rapid colorimetric method (Williams et al., 1970).

Sensory evaluation

Extrudates were evaluated by 10 panelists, who were students and faculty staff of the University of the West Indies. They were widely experienced in the sensory evaluation of food products. They rated the sensory attributes of color, flavor and texture, and overall acceptability according to a scale where 1 = unacceptable; 2 = poor; 3 = acceptable; 4 = good; and 5 = excellent. In addition, comments were required.

Extrudates of uniform size were served in sealed polyethylene bags, randomly coded by three digits. Two samples were presented per session and water was provided for rinsing between samples. Scores assigned to each quality attribute and to the formulas were subjected to analysis of variance to determine any significant differences. Sensory means were separated by Tukey’s test (Larmond, 1977). Sensory evaluation was conducted at the University’s Food Technology Laboratory, between 10:00 a.m. and 11:00 a.m.

Results and Discussion

Proximate composition

The proximate composition of cassava flour was crude protein, 1.5%-1.6%; crude fat, 0.6%-0.7%; crude fiber, 1.7%-1.8%; ash, 1.5%-1.7%; total carbohydrate, 85.2%-86.2%; and starch amylose, 16.4%. Crude protein of defatted soybean flour ranged from 52.1% to 52.2%. When 5% or 10% defatted soybean flour was added to cassava flour, the crude protein content rose from 1.38% ± 0.02% to 5.20% ± 0.03 or to 7.49% ± 0.05%, respectively.

Low protein (< 3%) staples such as cassava do not provide adequate protein for human requirements, even when ingestion exceeds caloric requirements. In contrast, diets with cereals (8%-10% protein) can meet adult protein requirements (Cheftel et al., 1985). Soya protein, rich in amino acid lysine (Harper, 1981b), can be used to fortify cassava flour.

Soybean flour was added to the cassava flour blend to increase the protein content, improve quality, and increase the yellow color of the extrudate. Badrie and Mellowes (1992b) found that soybean flour makes extrudates more attractive and yellower, resulting in a change of Munsell color notation from 4.62Y 6.38/1.75 to 5.04Y 6.46/2.19 at 5% soybean flour or to 5.30Y 6.46/3.10 at 10%. Thermal processing of food can increase the potential for interaction between lipids, proteins, carbohydrates, and their breakdown products (Bruechert et al., 1988). Maillard browning appeared the most likely reason for the color change.

Badrie and Mellowes (1992b) also found, however, that adding soybean flour reduced extrudate expansion and increased bulk density. Extrudate expansion was negatively correlated with crude protein (P < 0.01, r = -0.88).

Establishing processing conditions

Sensory attributes of extrudates depend on extrusion conditions and feed material. Badrie and Mellowes (1991b) established suitable processing conditions, evaluated on the bases of extruder performance and the physical and chemical properties of extrudates.

Optimal expansion (2.82) occurred at a feed moisture of 11% d.b.—the minimum moisture necessary to obtain a flow of the extrudate through the die (at 120-125 °C, screw speed 520 rpm, and feed rate 250 g/min). Lower feed moisture either blocked the rotation of the screw (there was no transition from the original floury nature to the ‘melted’ state typical of extrusion) or the extrudates emerged from the die in bursts. Only at 11% feed moisture was a more uniform moisture distribution and, thus, a more elastic dough achieved, resulting in a smooth surface texture. Foods with a lower moisture content also tend to be more viscous, the greater pressure differential resulting in better puffing.

The optimal expansion of cassava flour extrudate can be related to its microstructure. Scanning electron microscopy on cassava flour extrudates (Badrie and Mellowes, 1991a) at 11% feed moisture revealed wide porous air cells with thin cell walls. Extrudate expansion was positively correlated (P < 0.05, r = 0.80) to the water solubility index (WSI). At 11% moisture, the lowest texture values were recorded. Low-moisture extrusion, according to Harper (1989), can cause more mechanical damage (shear stress) to the feed, resulting in a softer texture. At 11% moisture, a more intense and attractive color (4.62Y 6.38/1.75) was also obtained.

Extrusion was stable between 100 and 125 °C, producing uniform, puffed products. Temperature increases from 100-105 °C to 120-125 °C brought corresponding increases in extrudate expansion. At higher temperatures (130-155 °C), extrudates became increasingly irregular, degenerating to rapidly ejected fragments. Temperatures above 125 °C probably resulted in a weakened structure and led to a rougher extrudate surface texture.

Establishing formulas

Because spicy snacks are a particular favorite of West Indians, powdered flavorings of onion, garlic, chili, paprika, and turmeric were included in the blends. Turmeric, a major ingredient of curry powder, also lent a more appealing yellow color. Other flavor enhancers were sucrose, salt, and monosodium glutamate. Dried skimmed milk provided both protein and flavor. Soybean oil was added at 4% level—a level at which Badrie and Mellowes (1992b) showed that lowest bulk density and highest extrudate expansion resulted, linked to increases in the WSI and total reducing sugars. Hsieh et al. (1990), working with maize meal extrudate produced by a twin-screw extruder, reported that adding salt and sugar enhanced radial and axial expansion but reduced bulk density and breaking strength.

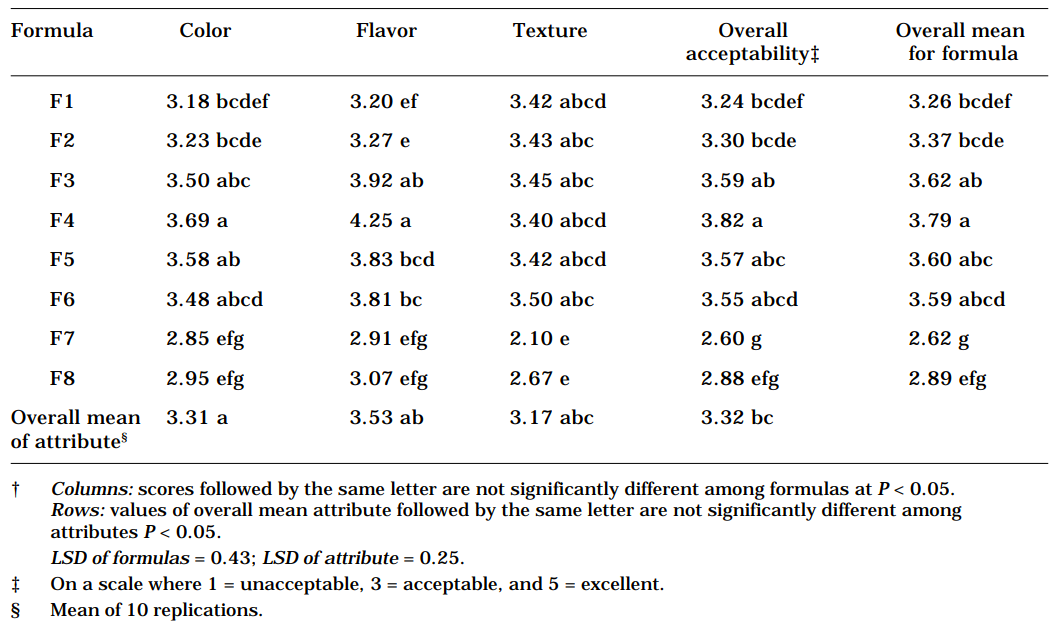

For the first formula (F1), sensory scores for all parameters were better than acceptable, that is, higher than 3 (Table 1). But panelists’ comments revealed that the color was unevenly distributed and too yellow. Extrudates were also too spicy and too salty, with a distinct taste of turmeric. Expansion was acceptable, but texture was slightly hard and the extrudate overly dense.

For the second formula, F2, adjustments were made to F1: the level of turmeric was reduced from 1% to 0.5%, and salt was reduced from 1.5% to 1.0%. Panelists again found the extrudates hard, too spicy, too yellow, and tasting of turmeric, although all sensory scores were acceptable (Table 1).

For formula F3, turmeric and paprika were reduced from 0.5% to 0.2%. A significantly better flavor and more acceptable color resulted (Table 1), but extrudates of F4 (0.1% turmeric and 1.5% spices) gained the highest overall acceptability, scoring highest in both color and flavor.

For F5, spice content was further reduced to 0.9%, but panelists found the extrudates too bland, and the flavor rating dropped from 4.25 (for F4) to 3.83.

To improve texture of the extrudates, the percentage of defatted soyflour was increased from 5% to 10% (F6), thereby reducing the total carbohydrate level. The result was a reduced extrudate expansion and an increased bulk density, but no significant change in texture. Adding cassava starch to cassava flour (i.e., increasing the total carbohydrate) tended to increase all textural attributes, the extrudate becoming less elastic or springy (Badrie and Mellowes, 1992b).

Badrie and Mellowes (1992b) showed that when soybean flour was added to cassava flour, the percentage of noncarbohydrate components (in particular, crude protein) increased. Extrudate expansion was negatively correlated with crude protein (r = -0.88, P < 0.01). Bulk density was negatively correlated (r = -0.96, P < 0.05) to extrudate expansion and positively correlated to crude protein (r = 0.89).

To reduce the bulk density of the extrudates, instant dry yeast was incorporated in the blend at 1.0% (F7) and 1.5% (F8). However, these additions resulted in unacceptable sensory scores. The effectiveness of sodium bicarbonate (baking powder) or maize amylose on reducing extrudate bulk density will be assessed in a later study. Although amylose tends to provide surface regularity and lightness, cassava starch or flour has too low an amylose content (16.4%) and produces denser, less radially expanded extrudates (Badrie and Mellowes, 1992a).

Sensory scores

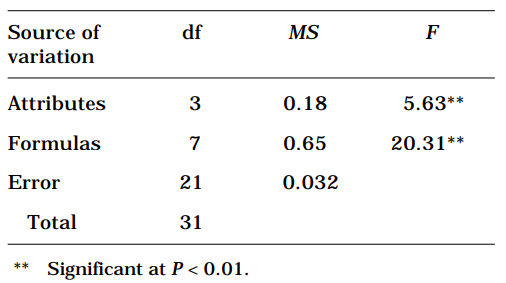

Analysis of variance indicated significant differences at both 5% and 1% level for sensory attributes and formulas (Table 2).

Flavor received the highest overall mean score (3.53, i.e., better than acceptable), with texture (3.17) registering the lowest, although also better than acceptable. Only F7 and F8 proved unacceptable (Table 1). Panelists commented on the unique flavor of cassava extrudates. However, they tended to rate texture lower because of their tendency to compare cassava extrudates with the popular maize extrudates. Cereals have excellent expansive properties and are well suited to thermal extrusion.

As Stanley (1986) observed, texture is the major obstacle in remodelling ingredients into acceptable foods. To produce products in the highly acceptable or excellent categories, panelists recommended lightening texture and reducing bulk density and surface irregularity of extrudates.

The F4 overall rating of 3.79 was significantly (P < 0.05) higher than other formulas.

Conclusions

Distinctive and acceptable extrudates can be produced, using cassava flour as the main ingredient. The study pointed to texture, bulk density, and surface regularity as areas requiring attention. Flavor achieved the highest overall rating, attributable to the 1.5% spice in most formulas. Except for F7 and F8, to which dry yeast had been added, all formulas were acceptable. Formula F4 emerged as the best overall product, having scored the highest for flavor and color. Color was found to be most attractive when 0.1% turmeric was added.

Other formulas, especially those incorporating local ingredients, can be tried. Successful development of extruded cassava products for the snack food industry in the West Indies could give rise to competition with popular, established maize-based products, the meal for which must be imported. Extrusion is a rapidly growing food-processing operation and extruded spicy snacks are popular in the West Indies, but more trials and consumer-type sensory evaluations are necessary before cassava-based extruded snacks can enter the local market.