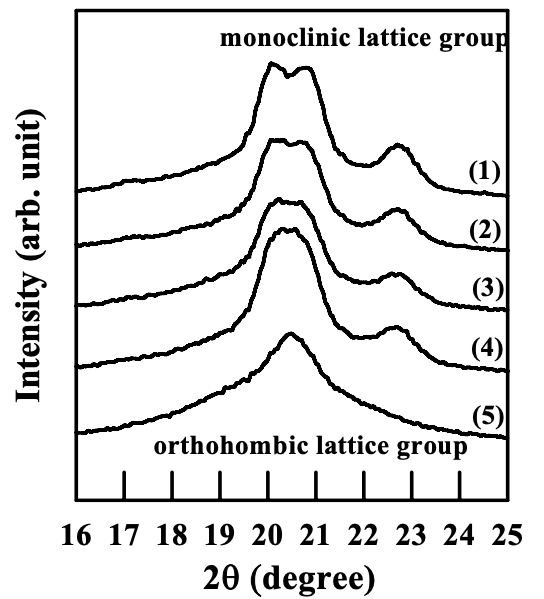

Wide-angle X-ray diffraction (WAXD) was used to investigate whether or not the crystalline structure of EVOH was influenced by the hydrogen bonding between EVOH and a modified starch in a blend. Previous research reported that the crystalline structure was largely affected by the amount of vinyl alcohol groups in EVOH. The crystalline structure takes orthorhombic lattice when the amount of vinyl alcohol groups is lower than 20 mol %, and takes monoclinic lattice when the amount of vinyl alcohol groups is higher than 20 mol %. It was also found that the composition-dependence of crystalline structure described above is only valid for slow crystallized samples. Thermal history also has an influence on the crystalline structures of EVOH. The literature showed that various cooling rates or crystallization temperatures could induce a change in crystalline lattice between monoclinic lattice and orthorhombic lattice.

- Miscibility of Blends Based on Modified Starch and EVOH Characterized by Phase Diagrams

- Hydrogen Bonding in Blends based on Modified Starch and EVOH Characterized by DSC and FTIR

- Mechanical Properties of Blends based on EVOH and Modified Starch

Figure 5.14 gives WAXD patterns of neat EVOH samples at various annealing temperatures. It is clearly seen that the diffraction patterns of EVOH are largely influenced by crystallization temperature. The quenched sample has a pattern characteristic of an orthorhombic lattice, with the (110) reflection peak being located at 20.5o (2θ). With increasing crystallization temperature, the (110) reflection peak is broadened and split into two monoclinic reflection (110) and (110) peaks. This change in the crystallization morphology was not observed during a typical temperature scan of the samples, even at the relatively slow ramp speed of 5 oC/min, because of its rather slow crystallization kinetics.

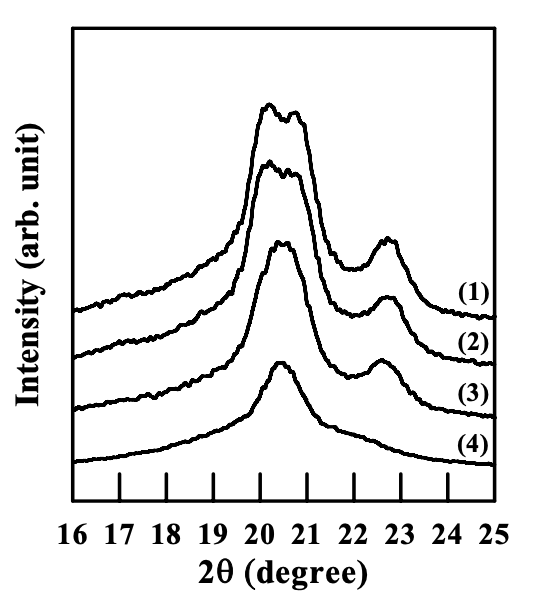

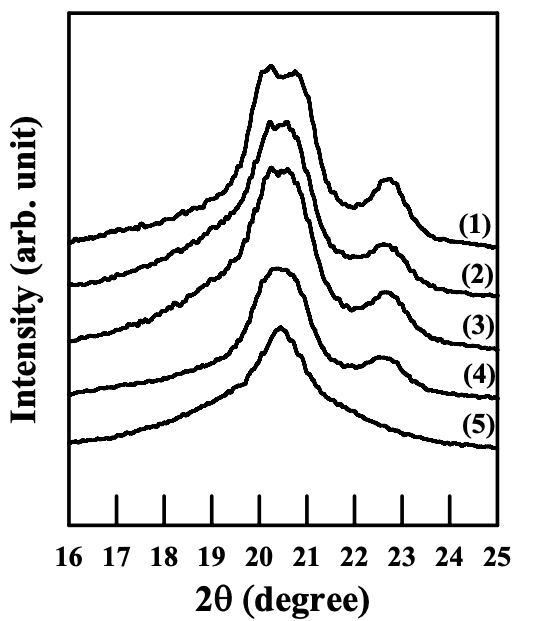

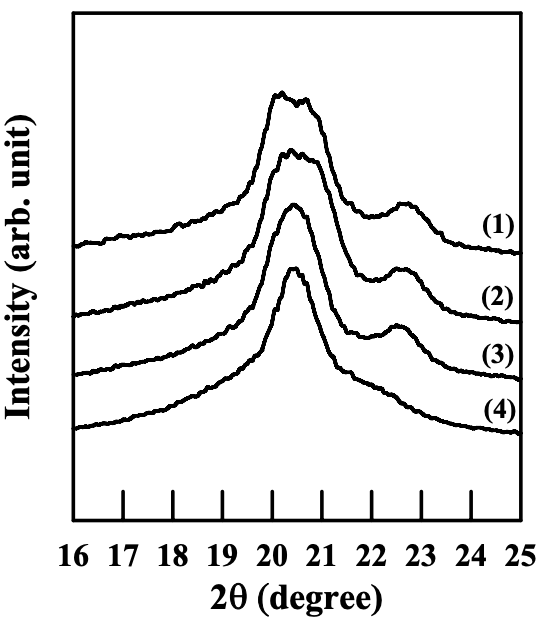

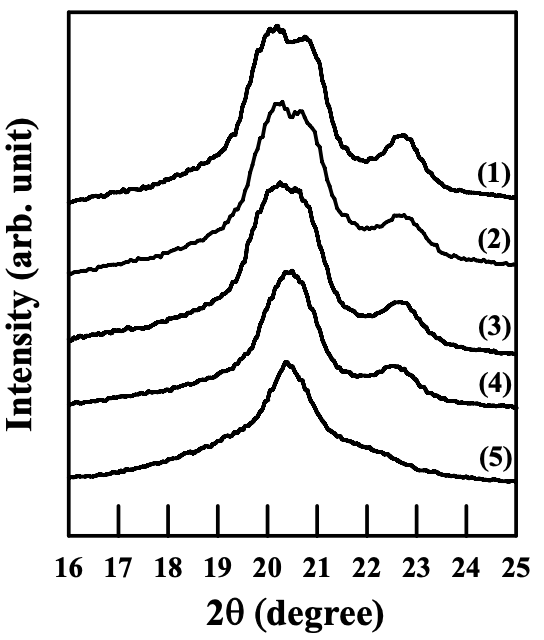

The change in crystalline morphology described above in neat EVOH has been reported. Figures 5.15 to 5.18 give WAXD patterns of the blends based on EVOH and a modified starch, crystallizing at various temperatures. The reflection peaks shown in the WAXD patterns of the blends are ascribed to the crystalline phase of EVOH in the blend (the modified starch is amorphous). Referring to Figures 5.15 to 5.18, it is shown that the change in the crystalline morphology in a blend with increasing crystallization temperature is similar to that in neat EVOH (see Figure 5.14).